Production process for firecracker fuse

A production method and fuse technology, applied to fuzes, offensive equipment, explosives, etc., can solve the problems of large amount of fuse stored in fuses and affect production safety and efficiency, and achieve high production efficiency, safe and reliable production equipment, and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

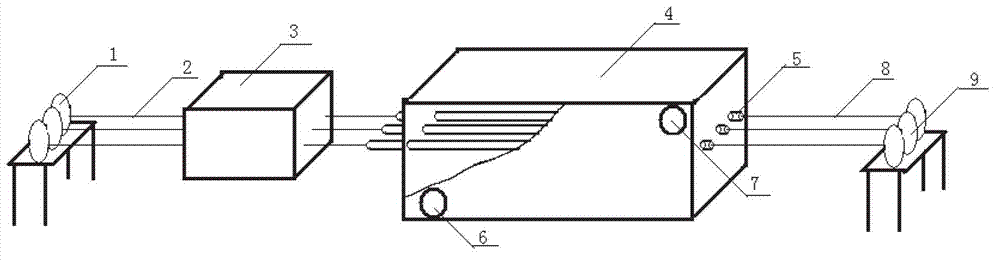

[0018] The production method of the firecracker fuse of the present invention is: take by weighing 4 kg of raw material potassium perchlorate; 3 kg of barium nitrate; 0.2 kg of potassium hydrogen phthalate; 2 kg of hemp stalk charcoal or flue-cured tobacco stem charcoal powder; 0.6 kg of titanium powder ; Mix 0.2 kg of aluminum powder evenly; add water to the uniformly mixed raw materials to make a paste: pass the nitrated cotton thread through the prepared raw material paste, so that the cotton thread is evenly coated with the fuse powder and dried in the air Or dry, cut into sections and package, store indoors. The production method of the firecracker fuse of the present invention consists of a cotton thread ball 1, a cotton thread 2, a liquid medicine tank 3, a heating and drying water tank 4, a drying pipe 5, and a fuse ball 9 connected in series to form production equipment; Corresponding small holes allow the cotton thread 2 to enter the liquid medicine tank 3 from one s...

Embodiment 2

[0020] The production method of the firecracker fuse of the present invention is: take by weighing 4kg of raw material potassium perchlorate; 2.8 kg of barium nitrate; 0.2 kg of potassium hydrogen phthalate; 2.2 kg of hemp stalk charcoal or flue-cured tobacco stem charcoal powder; 0.5 kg of titanium powder ; Mix 0.3 kg of aluminum powder evenly; add water to the uniformly mixed raw materials to make a paste: pass the nitrated cotton thread through the prepared raw material paste, so that the cotton thread is evenly coated with the fuse powder and dried in the air Or dry, cut into sections and package, store indoors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com