On-line detection system and detection method for machining accuracy of parts for CNC lathes

A detection system and parts processing technology, which is applied in general control systems, control/regulation systems, metal processing equipment, etc., can solve the problems of low detection efficiency, long time consumption, poor detection stability, etc., and achieve simple operation, improved flexibility, The effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

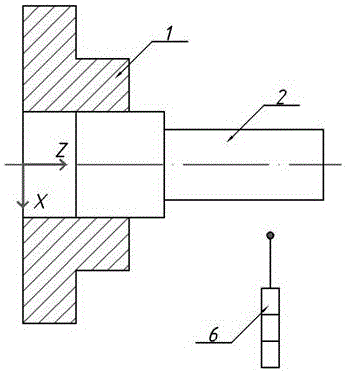

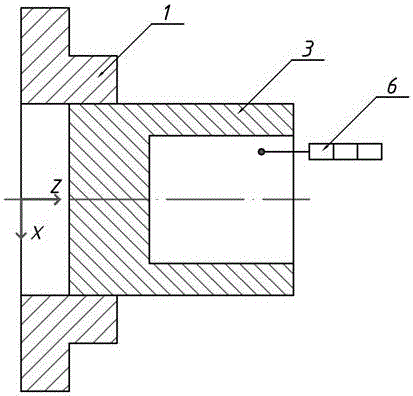

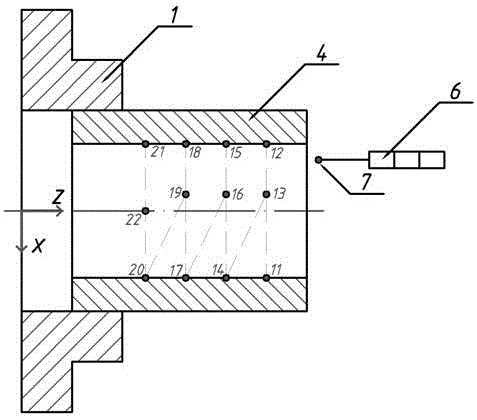

[0039] The structure diagram of the present invention is as figure 1 , 2 , 3, and 4, the technical solution of the present invention is: the part processing accuracy online detection system for CNC lathes of the present invention includes a chuck 1, a workpiece, and a lathe probe 6, wherein the workpiece is mounted on the chuck 1 , The lathe probe 6 is installed on the side of the workpiece, and the signal output end of the lathe probe 6 is connected to the controller of the detection system. The workpieces described in the present invention are respectively figure 1 , figure 2 , image 3 , Figure 4 The workpieces 2 to 5 marked in , and the workpieces 2 to 5 are parts of different shapes.

[0040] The above-mentioned lathe probe 6 adopts a trigger probe.

[0041] The present invention faces the detection method of the on-line detection system of part processing precision of numerical control lathe, comprises the following steps:

[0042] 1) Install the lathe probe 6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com