Floating plate type crushing device of crusher

A technology of crushing device and crushing disk, which is applied in the direction of grain processing, etc., can solve the problems of crushing shaft, small crushing disk, backward crushing device, hindering crushing function, etc., and achieve the effects of improved crushing efficiency, safety, stability and reliability, and reasonable functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

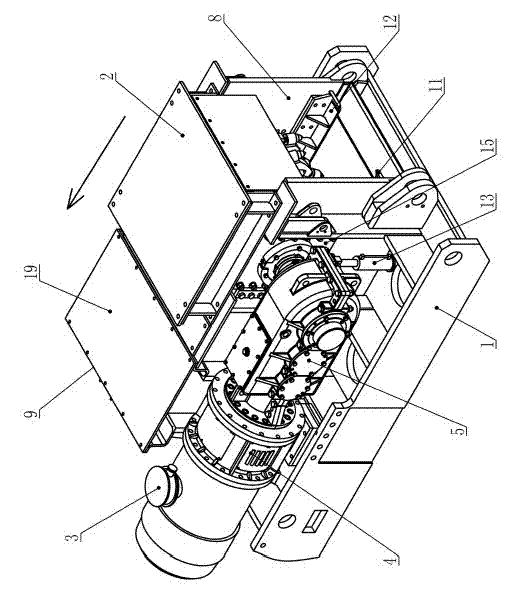

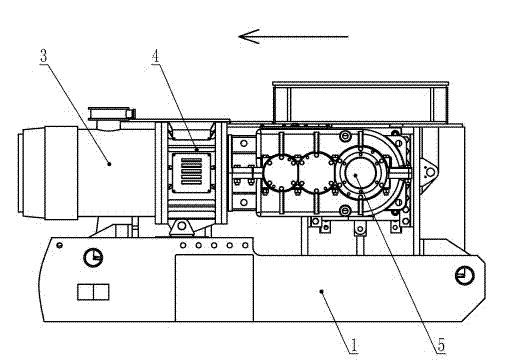

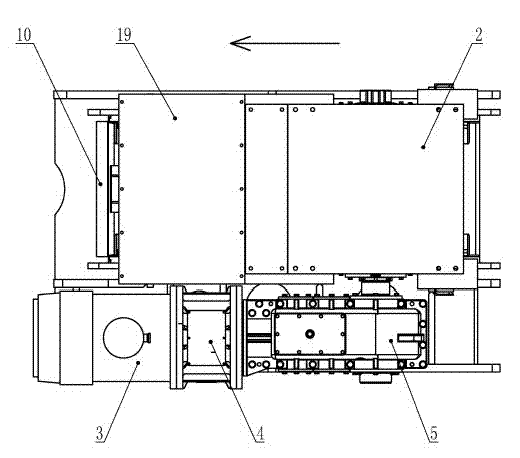

[0020] figure 1 , 2 , 3, and 4 show the structure diagram of the crushing device. The position and connection relationship of each part must be correct and the installation should be firm.

[0021] The bottom of the crushing device is a frame 1, and one part on the frame is a crushing groove 8, and the front part of the crushing groove 8 is a coal discharge groove 9 and a coal discharge plate 10; The second fixed plate 16 is equipped with a broken shaft 6 between the first fixed plate 15 and the second fixed plate 16. On the broken shaft 6, the first broken disc 7, the second broken disc 17, the same shape and specifications are arranged side by side. The third crushing disc 18, the crushing shaft 6 is connected with the reducer 5 mounted on the frame 1, the reducer 5 is connected with the coupling 4, and the coupling 4 is connected with the motor 3; Support oil cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com