Plug-type connector for media lines

A technology of plug-in connectors and connectors, applied in the direction of couplings, mechanical equipment, etc., can solve the problems of large overall size, etc., and achieve the effect of compact structure, easy operation and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

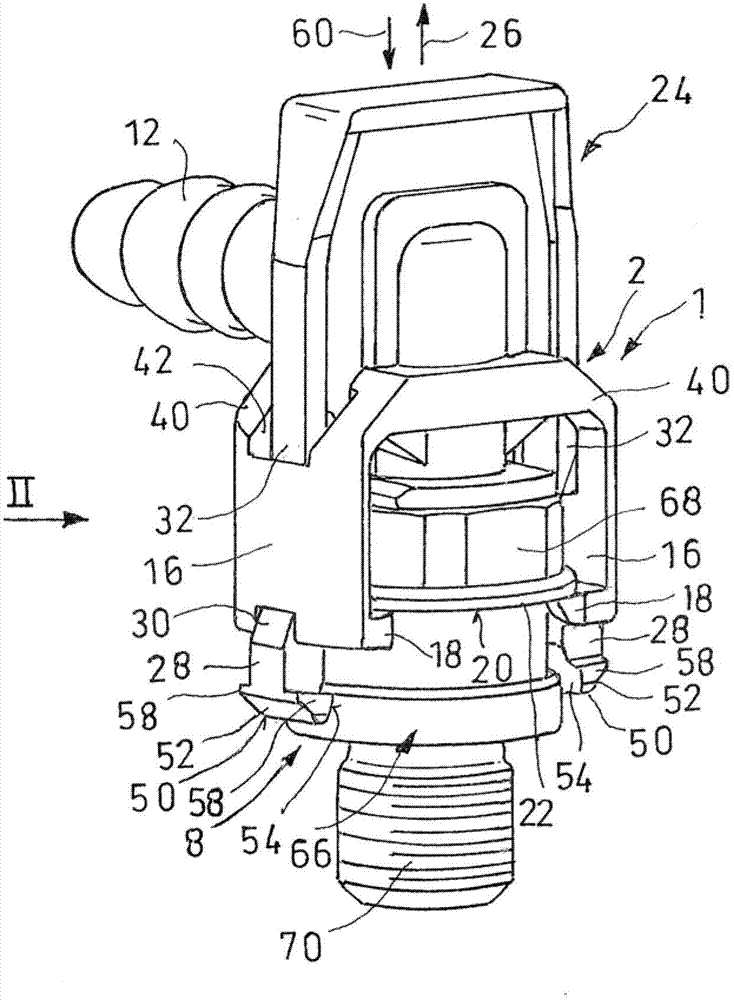

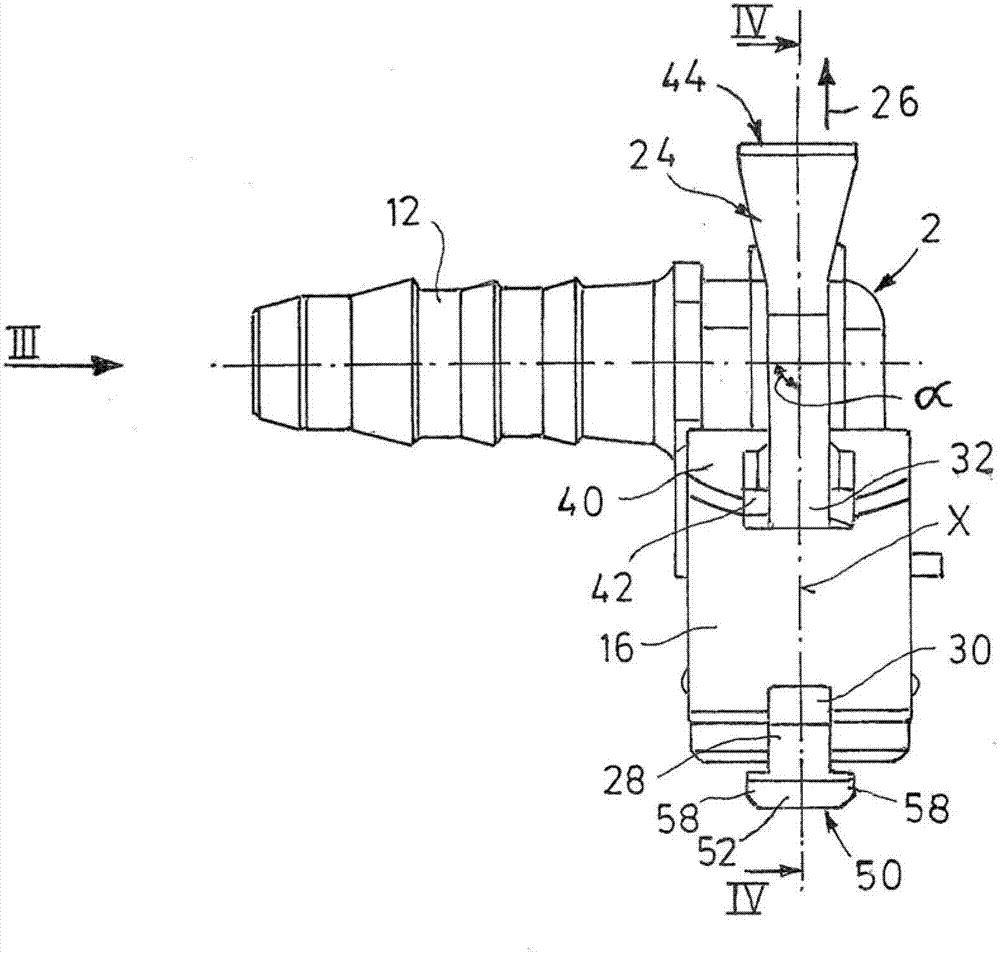

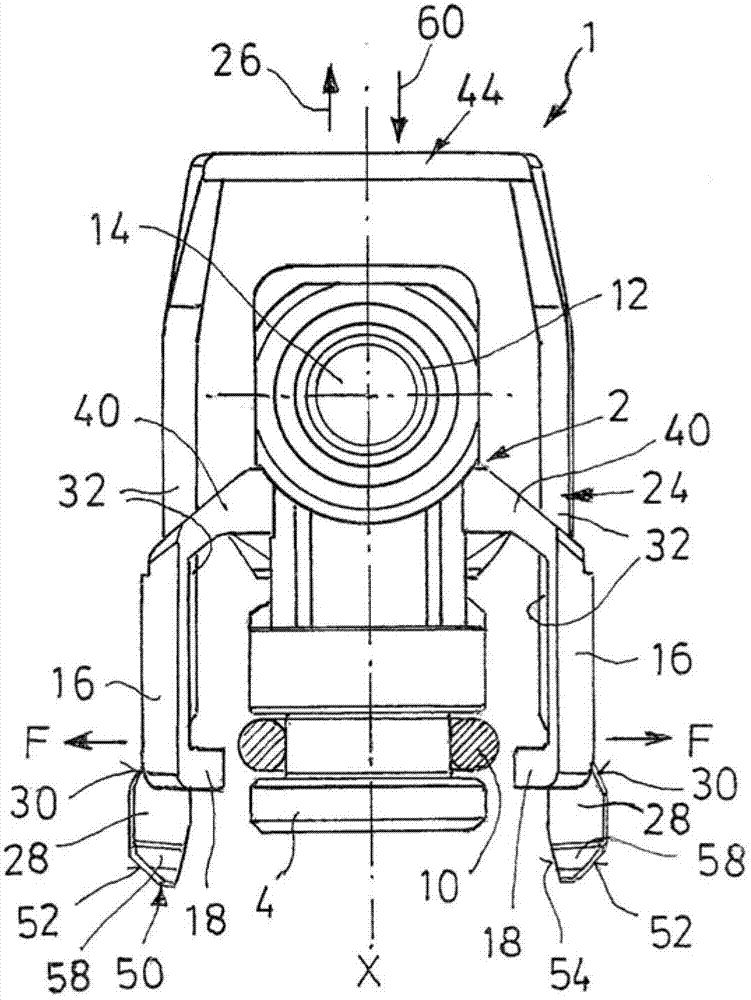

[0025] In the different figures, identical components are always assigned the same reference numerals and are therefore usually only described once in each case.

[0026] The plug connector 1 according to the invention comprises a plug part 2 with a plug pin 4 . The plug rod 4 can be inserted into the socket 6 of the receptacle 8 in the direction of the longitudinal axis X of the connector, while the plug part 2 can be releasably locked by means of a latching device in the inserted position of the plug rod 4 Hold, that is to say, this plug-in connection is locked (fixed) and cannot be accidentally released, but, in order to release the plug-in connection when necessary, this lock can be removed (disengaged). For sealing the plug-in connection, a circumferential gasket 10 is provided, which is preferably arranged in the outer annular groove of the plug-in rod 4 .

[0027] The plug part 2 is used to connect (at least) one (not shown) medium line (hose or pipe) to the receptacle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com