Push screw device and roll forming machine

A screw and moving roller technology, applied in the field of roll forming machines, can solve the problems of easy adhesion of raw materials or retention of scoop shells, overload and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

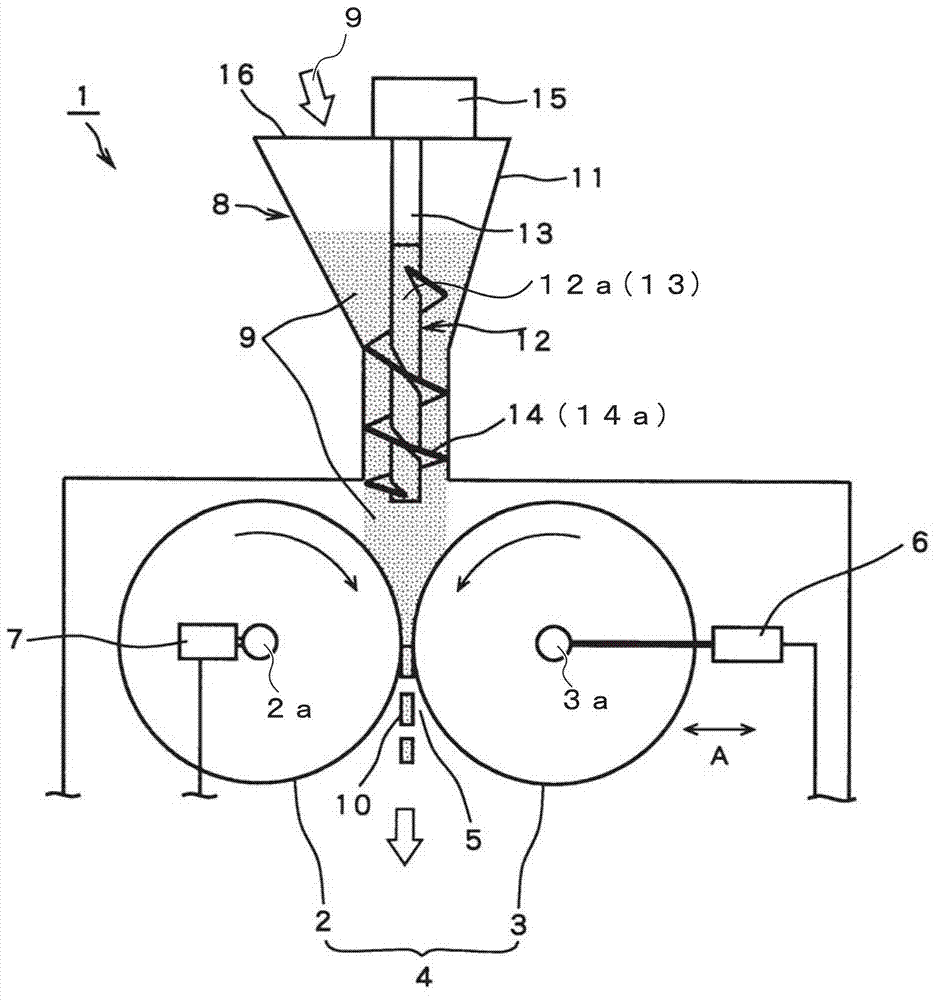

[0031] A press-in screw device for a briquette machine (hereinafter referred to as a press-in screw device) according to an embodiment of the present invention and a briquette machine (roll former) equipped with the same will be described below with reference to the drawings.

[0032] figure 1 It is a vertical cross-sectional view showing a schematic structure of the briquette machine 1 of the present embodiment.

[0033] This briquetting machine 1 is provided with: a casing 11 for storing raw materials 9 and a bucket 8 for pressing the raw materials 9 in the casing 11 to the lower part of the screw device 12, and by sandwiching the raw material 9 extruded from the bucket 8, The raw material 9 is a pair of fixed roll 2 and movable roll 3 for press molding.

[0034] The fixed roll 2 and the movable roll 3 of this briquette machine 1 have rotating shafts 2 a and 3 a parallel to each other in the horizontal direction, respectively, and rotate inwards of each other in plan view....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com