Tire vulcanizing apparatus

A technology for tire vulcanization and finished tires, applied to tires, other household appliances, household appliances, etc., can solve the problems of uneven pressure on the upper mold 4, bending of the connecting rod 13, etc., and improve durability, reliability, and quality Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Next, one embodiment of the tire vulcanizer of the present invention will be described based on the drawings.

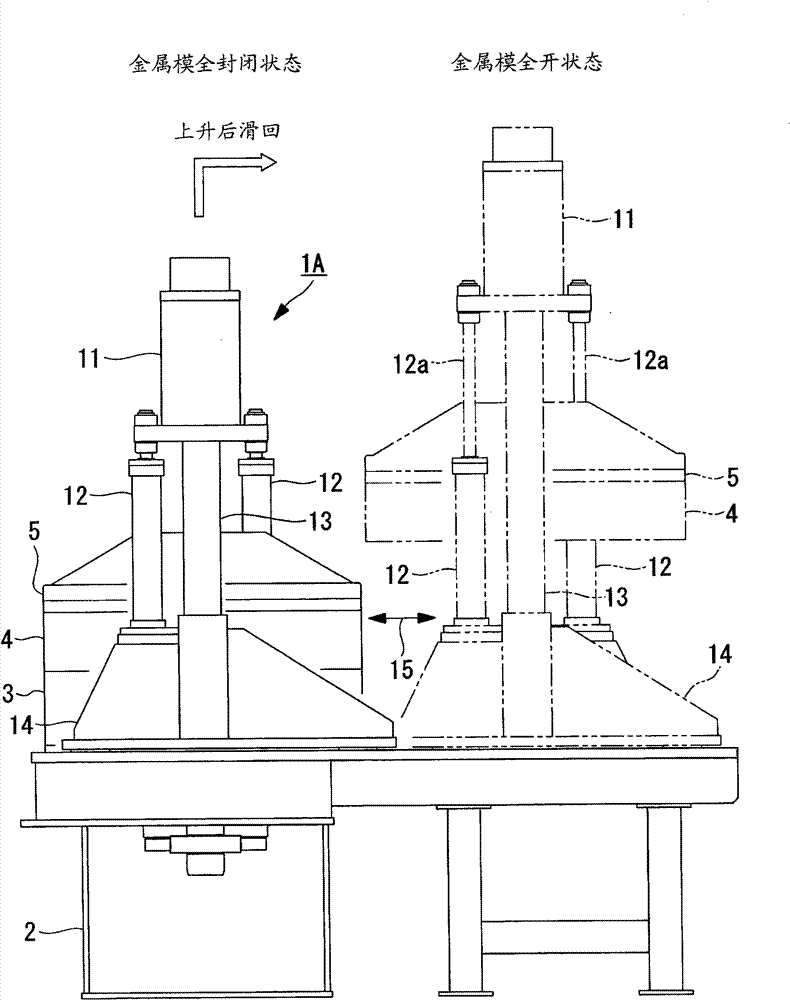

[0049] Figure 1~4 The shown tire vulcanizer 1A is a device that puts a green tire into a die that can be separated into a lower die 3 and an upper die 4 , heats and presses it, and vulcanizes it into the final shape of a finished tire. In addition, in order to form the inner shape of the tire, an air bag (not shown) is disposed inside the mold.

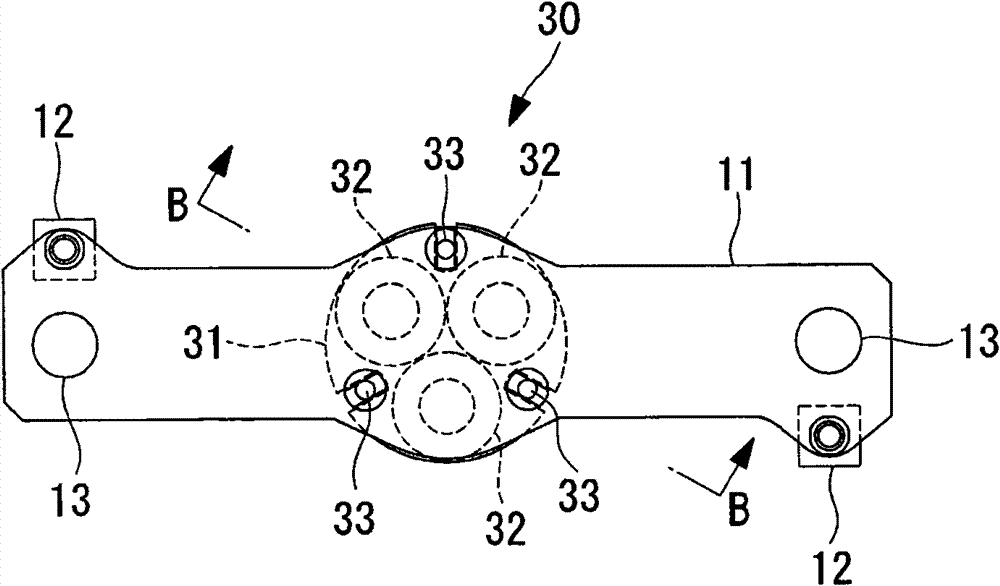

[0050]This tire vulcanizer 1A is installed on a base member 2 fixed to a foundation. A fixed lower mold 3 and a moving trolley 14 capable of moving back and forth in the horizontal direction are provided on the base member 2 . In addition, the lifting / sliding mechanism 10A of the upper mold 4 and the pressurizing cylinder mechanism 30 are provided on the moving trolley 14, and can move integrally.

[0051] In addition, the tire vulcanizer 1A of the present embodiment includes a slide-back mechanism. For example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com