Silicon controlled rectifier driving method and device

A thyristor drive, thyristor technology, applied in the field of circuits, can solve the problem of large drive loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

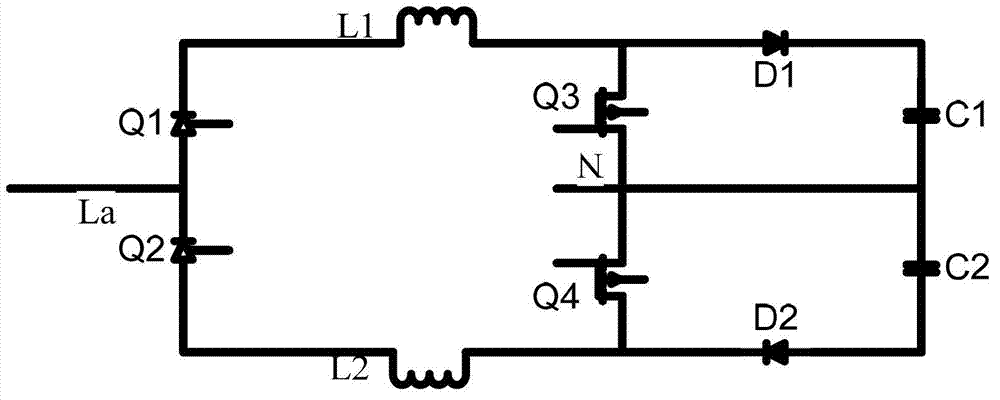

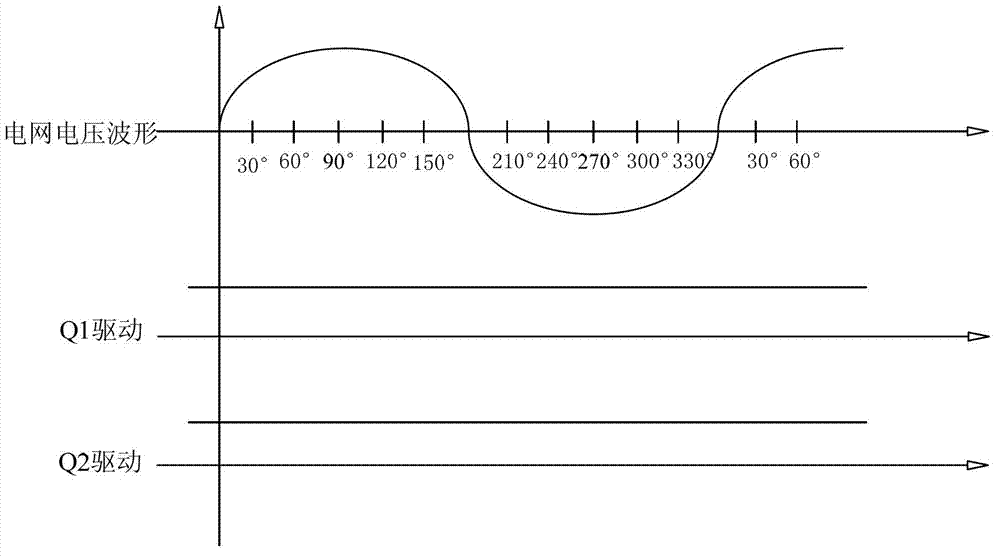

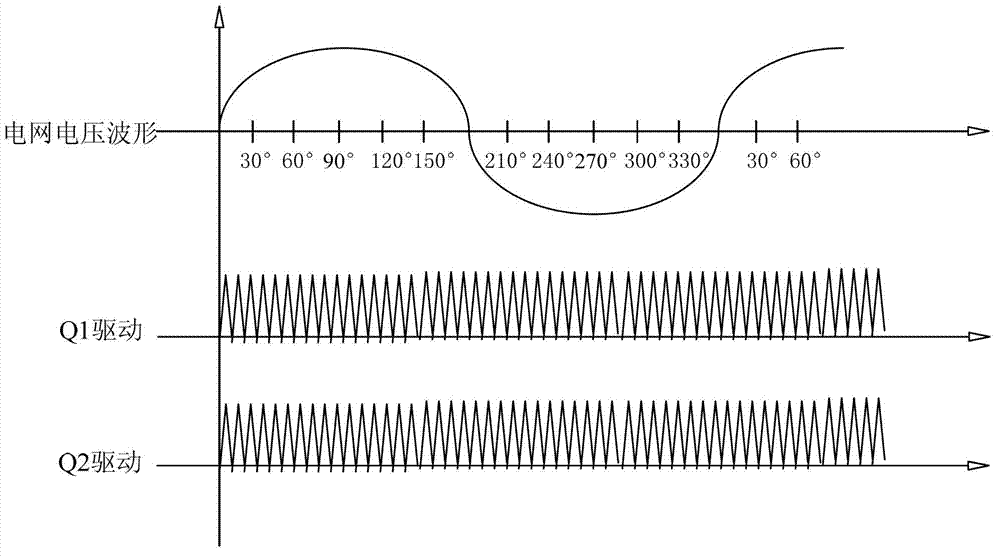

[0055] In the prior art, when the commercial power is working normally, the driving device for the thyristor generally continuously outputs driving signals to the first thyristor Q1 and the second thyristor Q2, and these two thyristors are used as diodes. from the aforementioned figure 1From the working principle of the dual BOOST circuit shown, it can be seen that the first thyristor Q1 needs to be turned on in the positive half cycle of the grid voltage AC, and the second thyristor Q2 needs to be turned on in the negative half cycle of the grid voltage AC. According to the reverse voltage isolation characteristics of thyristors, theoretically, in the prior art, the driving of the first thyristor Q1 and the second thyristor Q2 is continuously turned on. In the positive half cycle of the grid voltage AC, the second thyristor Q2 will be closed due to the negative voltage applied to both ends. Turn off, in the negative half cycle of the grid voltage AC, the first thyristor Q1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com