Concrete test loading device and test method under load and multifactor coupling

A technology of loading device and test method, which is applied in the direction of measuring device, using repeated force/pulsation force to test the strength of materials, instruments, etc., can solve the problems of thread wear, reduce the service life of the device, test accuracy, and high strength, and achieve cost reduction , avoid harmful substances erosion, increase the effect of loading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in more detail below in conjunction with accompanying drawing example:

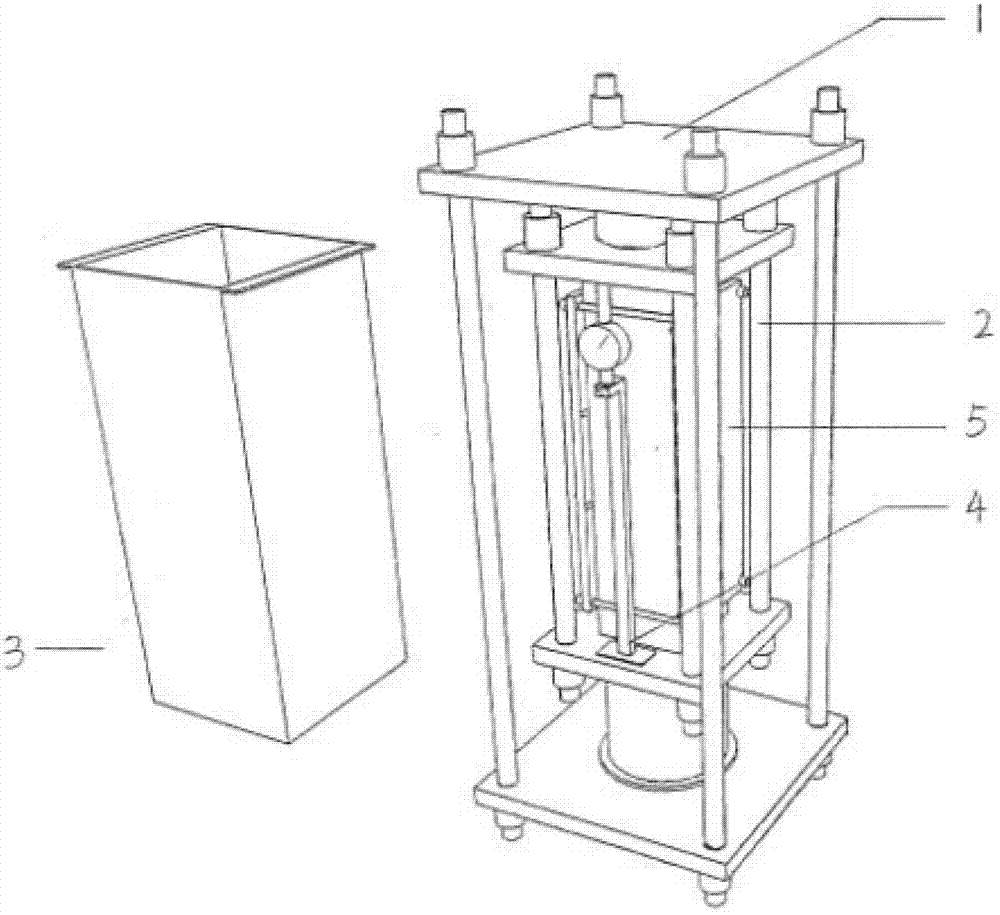

[0027] combine Figure 1-10 , The concrete test loading device under the load and multi-factor coupling action of the present invention is composed of five parts: a press 1, a main clamp 2, a test piece box 3, a sensor assembly 4, and a side clamp 5. Below in conjunction with accompanying drawing, connection mode and effect thereof of each part of the present invention are set forth as follows:

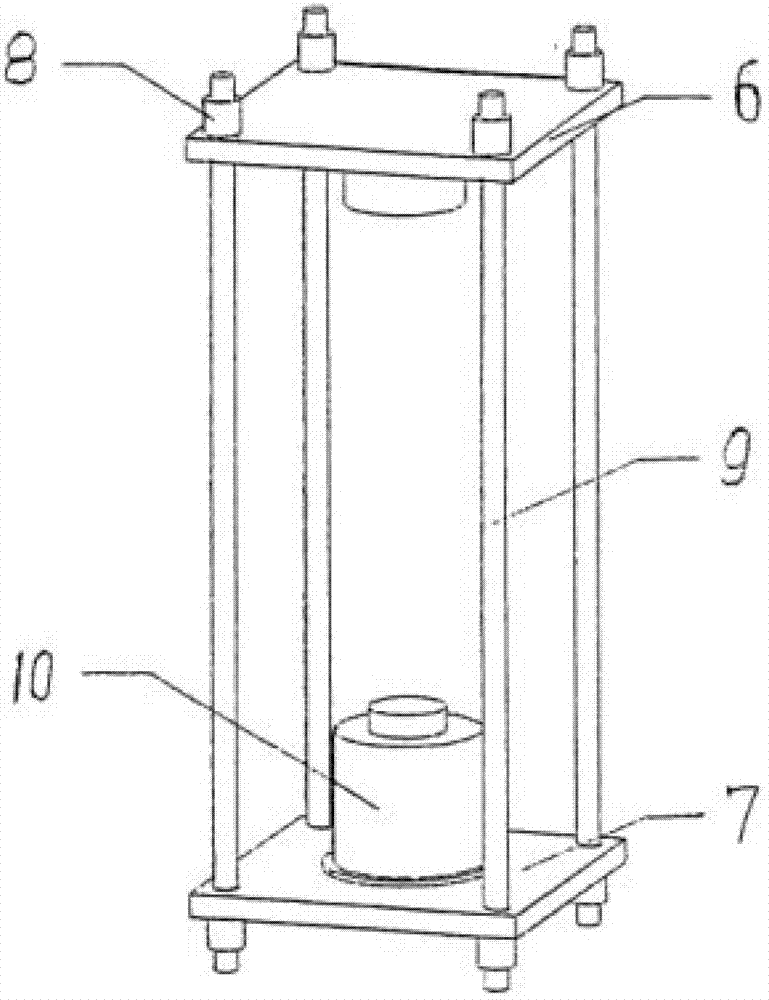

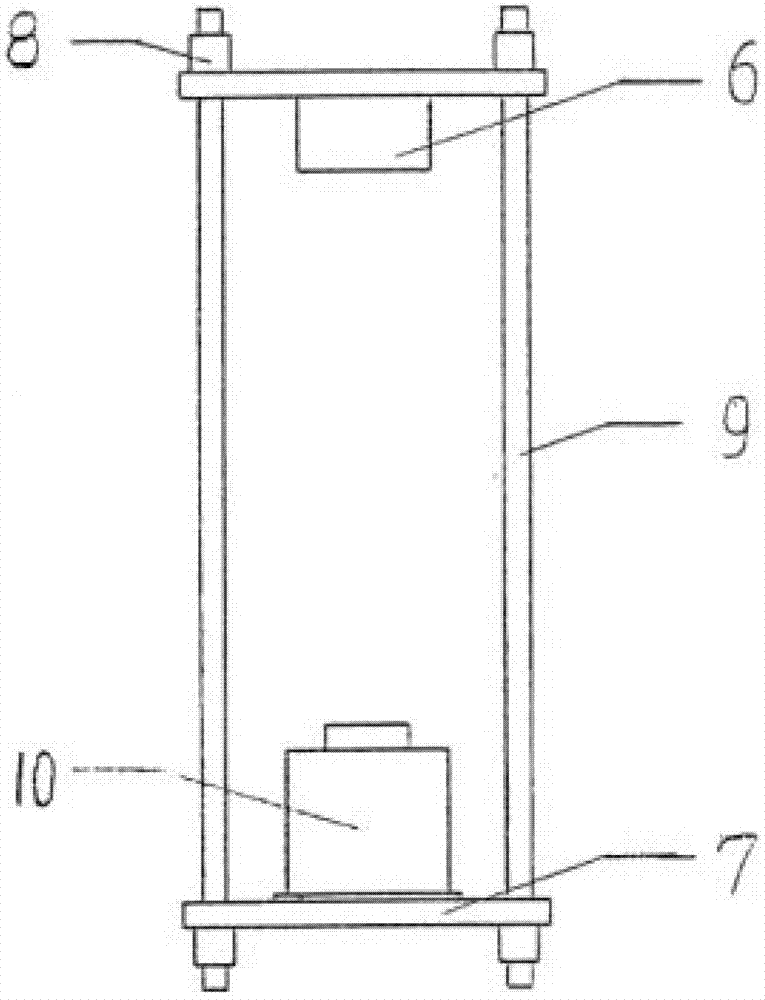

[0028] The press 1 includes an upper platen 6, a lower platen 7, a separate hydraulic jack 10 is placed in the center of the lower platen 7, and the two platens are connected by four pull rods 9 and 8 nuts 8 (see figure 2 ); the main fixture 2 includes two identical pressing plates 15, and the two pressing plates are connected by four pull rods 17 and 8 nuts 18 (see Figure 6 ); the side clamp 5 includes a left pressing plate 13 and a right pressing plate 12, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com