Device and method used for measuring film thickness

A technology for measuring devices and film thickness, applied in measuring devices, optical devices, instruments, etc., can solve the problems of narrow spectral width, low resolution, low precision, etc., and achieve expanded spectrum range, improved resolution, and high-precision film thickness measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

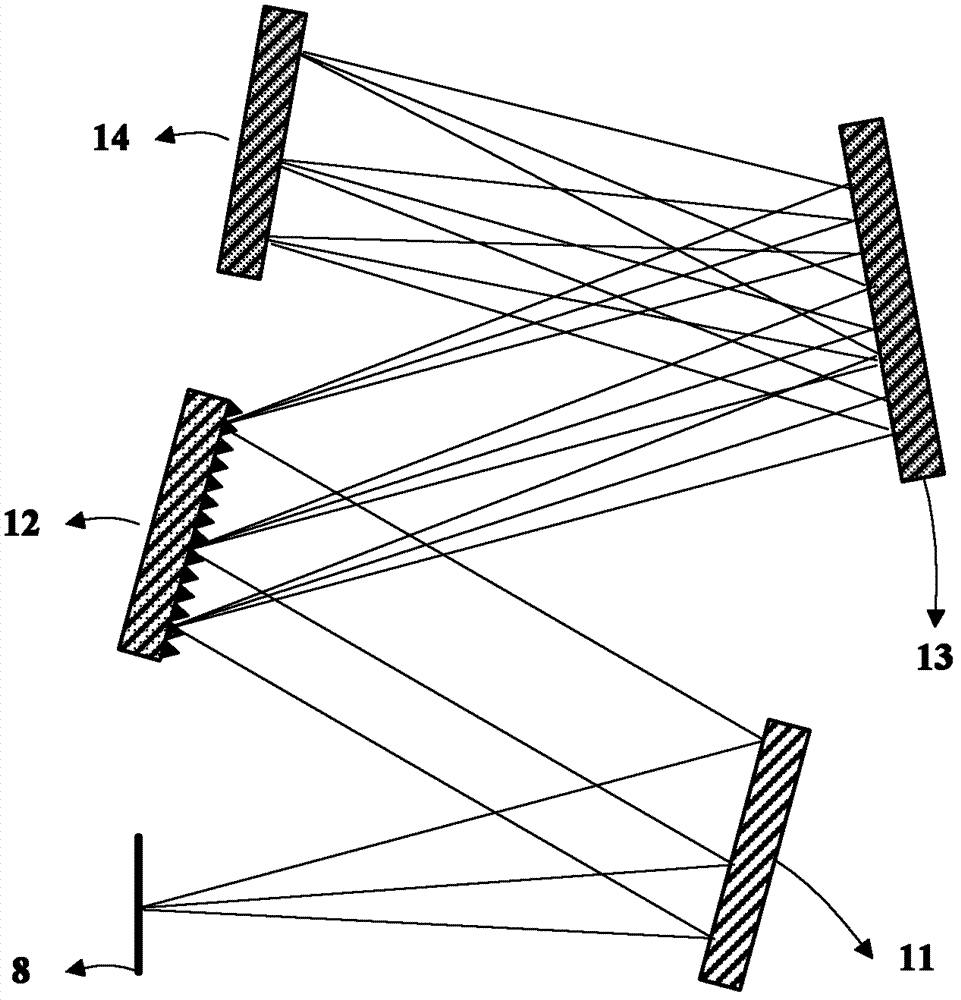

[0046] Since a prism can split a beam of light in a continuous spectrum, in some measurement systems that require high resolution, a prism can be used as a spectroscopic device to improve resolution.

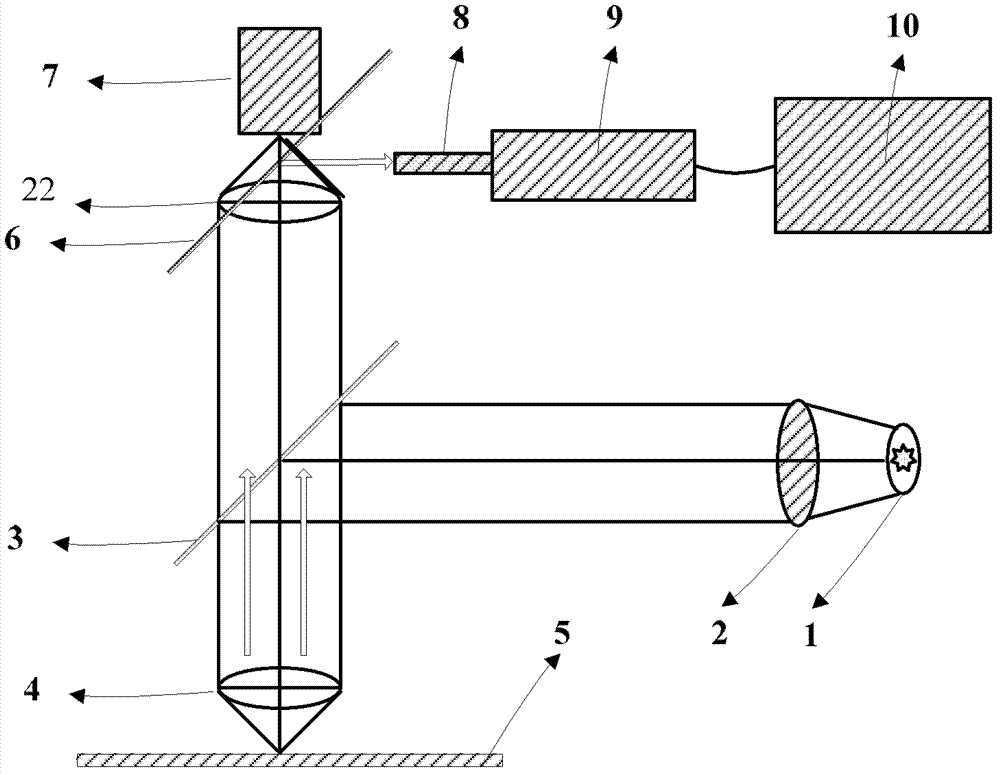

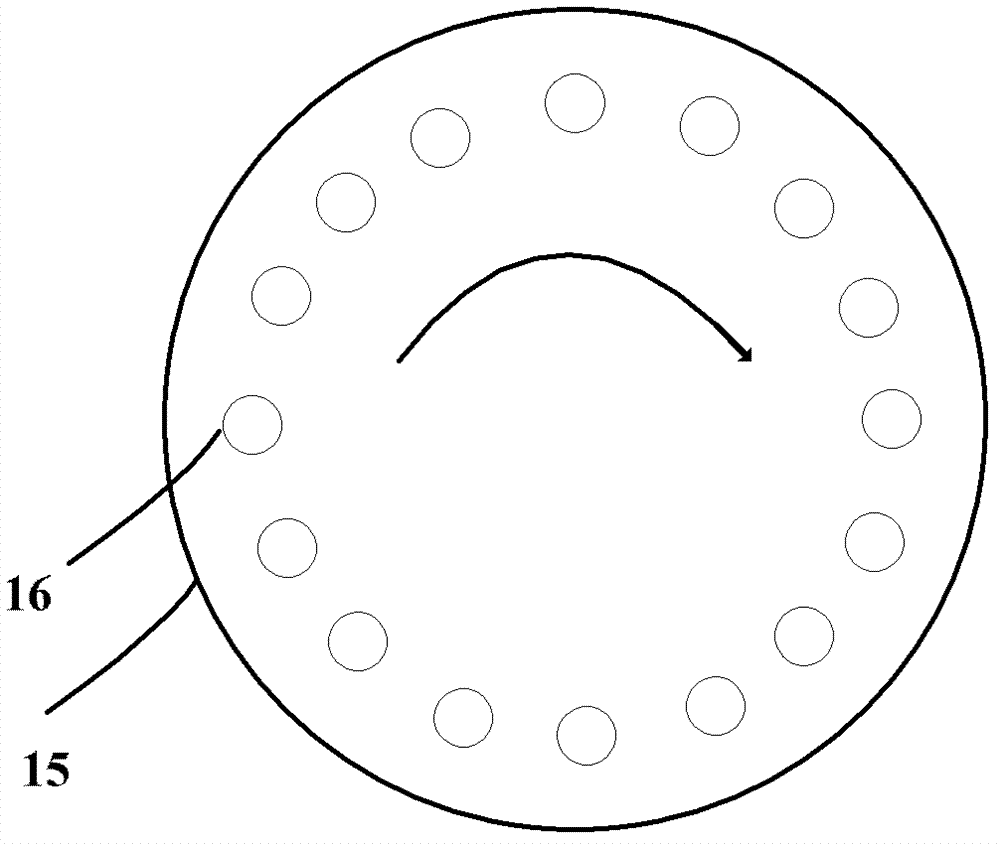

[0047] The basic idea of the present invention is: a kind of film thickness measuring device, comprises collimating lens, first half-mirror, objective lens, second half-mirror, collecting optical fiber, computer and spectroscopic unit; Wherein, said spectroscopic The unit is used to perform spectroscopic processing on the light collected by the collection fiber, and separate and obtain light of each wavelength; the computer is used to obtain the intensity of light of different wavelengths, and calculate the film thickness of the measured object.

[0048] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail by citing the following embodiments and referring to the accompanying dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com