Ventilation method for exploiting short distance coal bed in fire zone based on positive pressure ventilation system

It is a positive pressure ventilation and short-distance technology, which is applied in mine/tunnel ventilation, mining equipment, mining equipment, etc. It can solve the problems of complex air leakage rules, complex processes, and many air leakage channels, so as to overcome blindness and hysteresis, Guarantee the effect of safe and efficient recovery and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

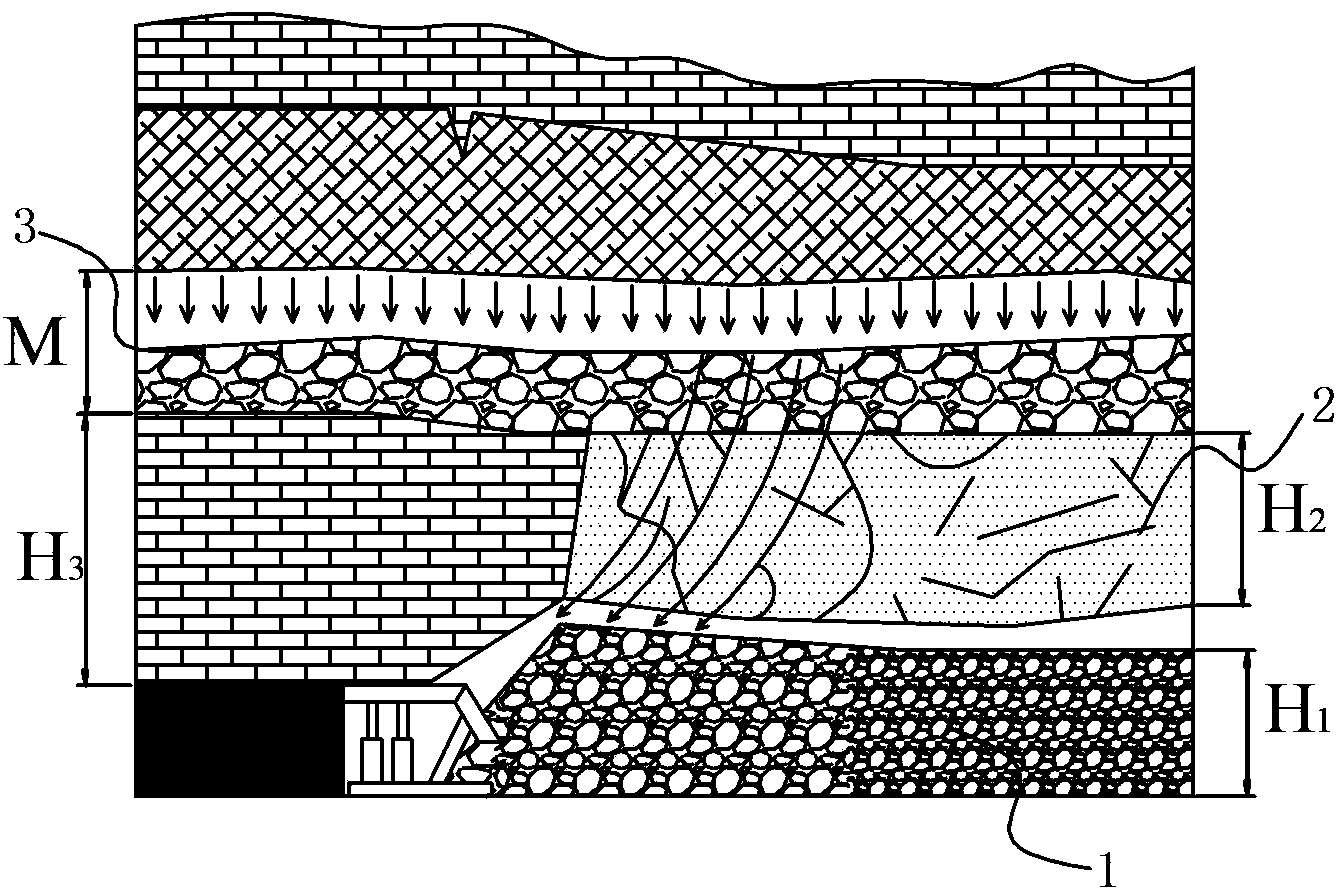

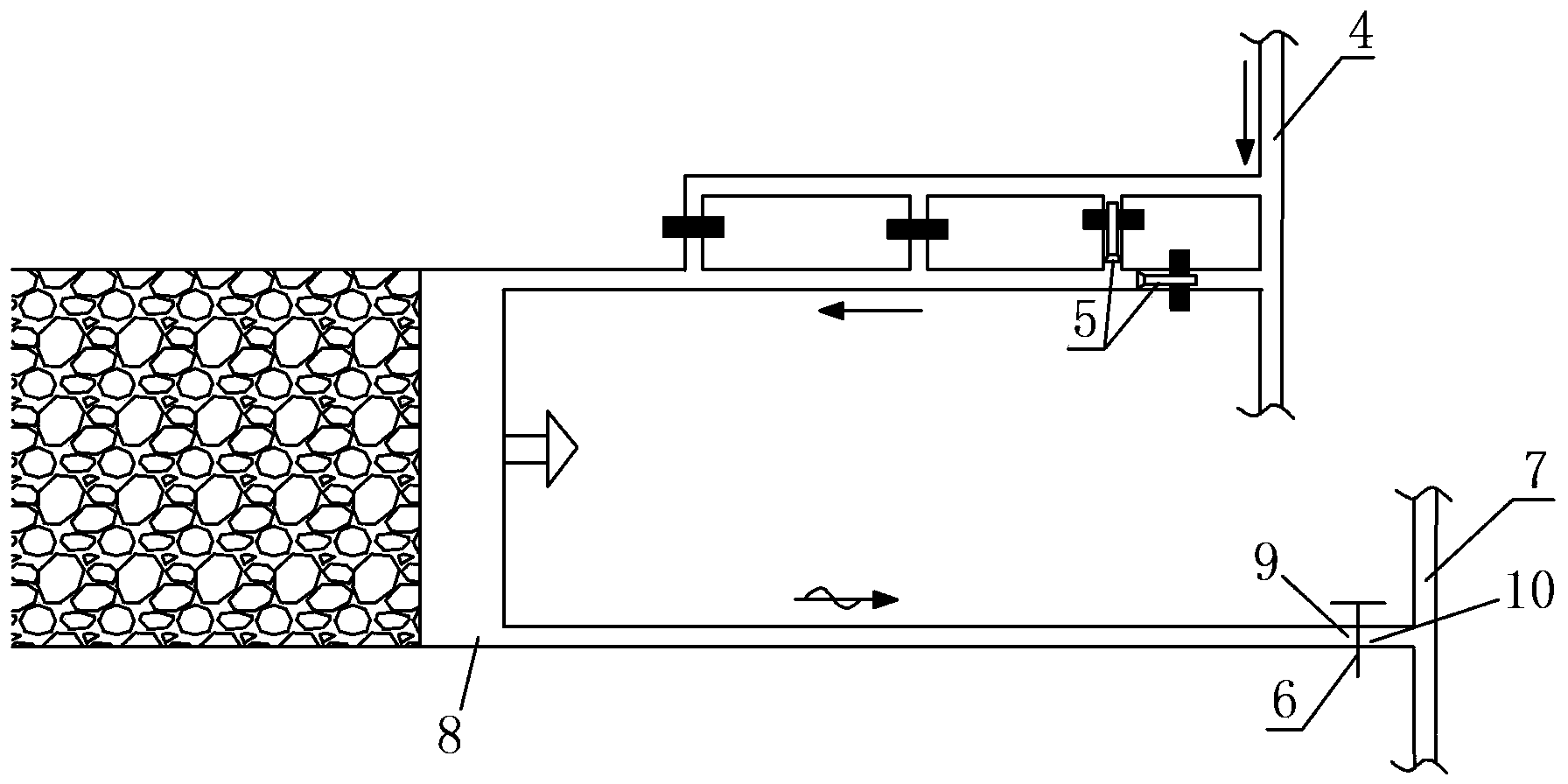

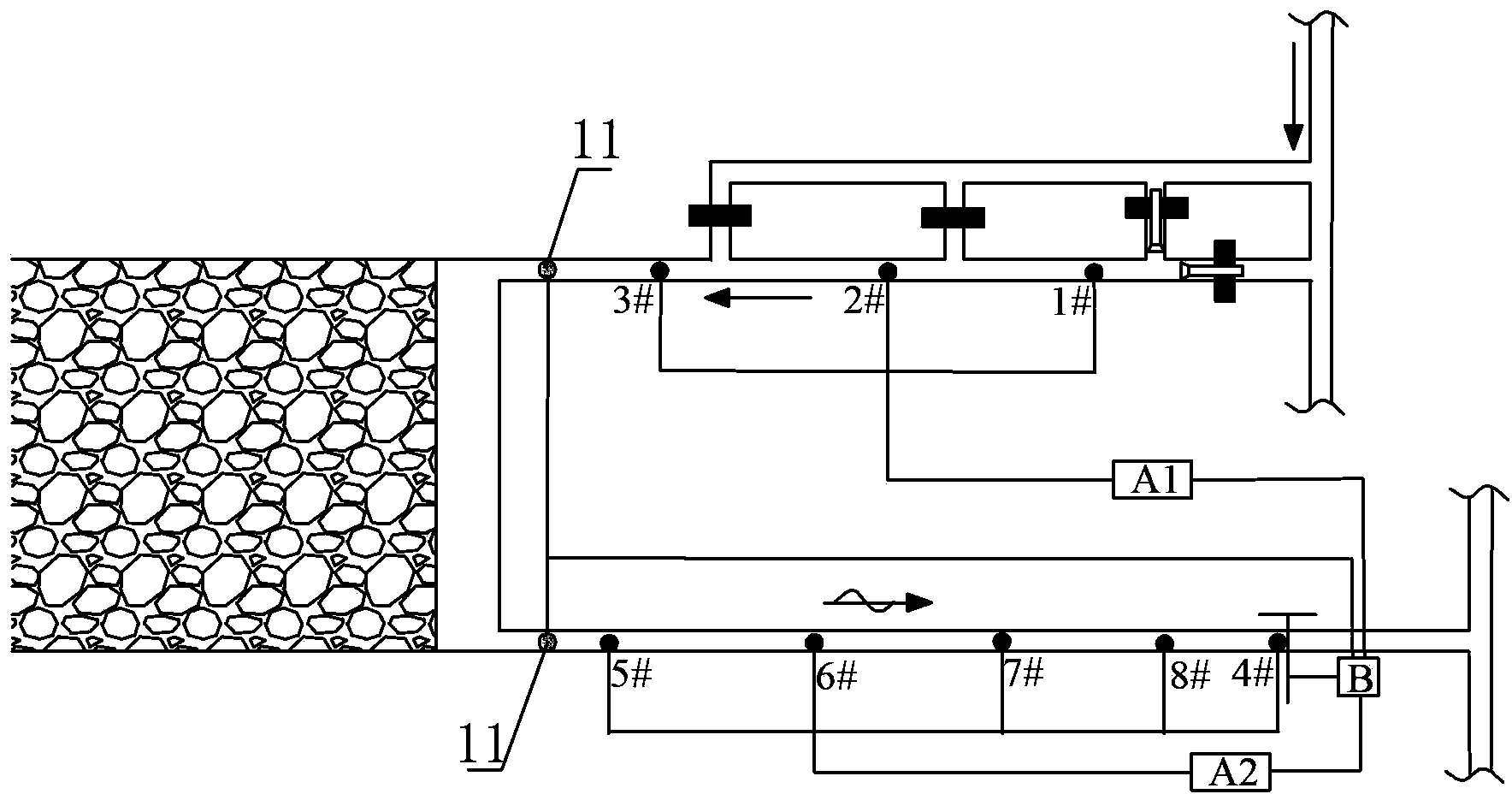

[0041]The present invention is based on the positive pressure ventilation system of the coal mining face, and based on the judgment of the connectivity between the coal mining face and the upper fire area in the short-distance coal seam, it is clear that the abnormal influx of harmful gas from the upper fire area of the coal mining face into the working face combined with the actual situation of the coal mining face, determine the safe pressure range of the lowest pressure energy area of the working face (at the return air corner), and then determine the coal mining work by measuring the ventilation parameters of the coal mining face and the law of energy conservation. According to the energy loss of the coal mining face, the safe adjustment range of the pressure difference of the return wind window is calculated, and based on this, combined with the automatic control technology, the change of the pressure difference between the front and rear (inside and outside) of the ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com