Process for manufacturing 17-4PH Martensite precipitation-hardening stainless steel forgings

A precipitation hardening and manufacturing process technology, applied in the field of manufacturing process of 17-4PH martensitic precipitation hardening stainless steel forgings, can solve the problems of high product scrap rate, reduce steel forgeability, affect steel structure and performance, etc. Low scrap rate, good effect of improving plasticity, organization and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The manufacturing process of the 17-4PH martensitic precipitation-hardening stainless steel forging of the present invention will be further described in detail through specific examples below.

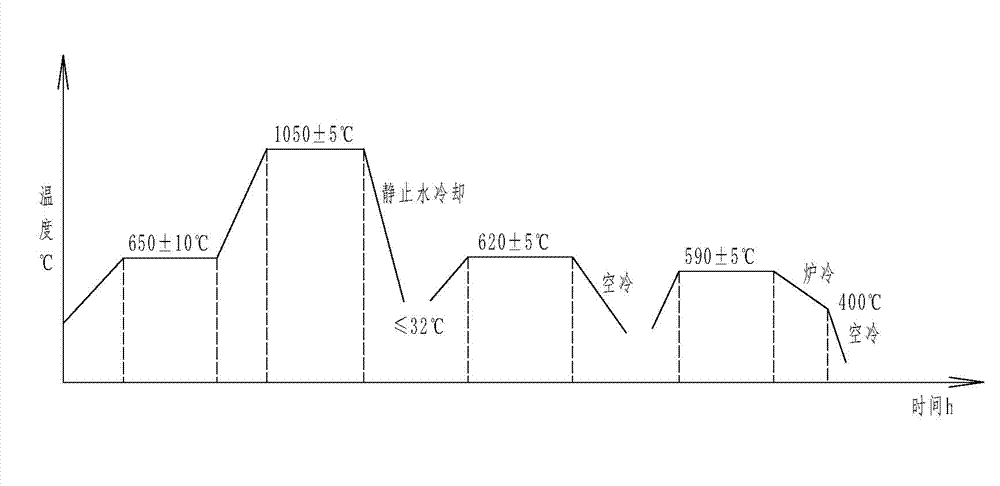

[0011] Such as figure 1 As shown, the manufacturing process of 17-4PH martensitic precipitation hardening stainless steel forgings includes the following steps:

[0012] Quenching: First, heat the workpiece to 650±10°C for the first heat preservation. The first heat preservation time is proportional to the thickness of the workpiece. When the thickness of the workpiece is 1 inch, the heat preservation time is 0.5 to 1 hour. After a period of time, heat the workpiece to 1050±5°C for the second heat preservation. The second heat preservation time is proportional to the thickness of the workpiece. When the thickness of the workpiece is 1 inch, the heat preservation time is 0.5 to 1 hour. After a period of time, put the workpiece into water for static water cooling until the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com