Solid fermentation device and method for white liquor

A solid-state brewing and liquor technology, applied in biochemical equipment and methods, wine cellar utensils, preparation of alcoholic beverages, etc., can solve problems affecting cellar wine quality stability, inconsistent quality, poor aroma, etc., to improve production Improvement of wine quality, alcohol content, and promotion of esterification and aroma production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Taking the fermentation process of Luzhou-flavor distiller's grains as the research object, the whole fermentation process lasted for 60 days.

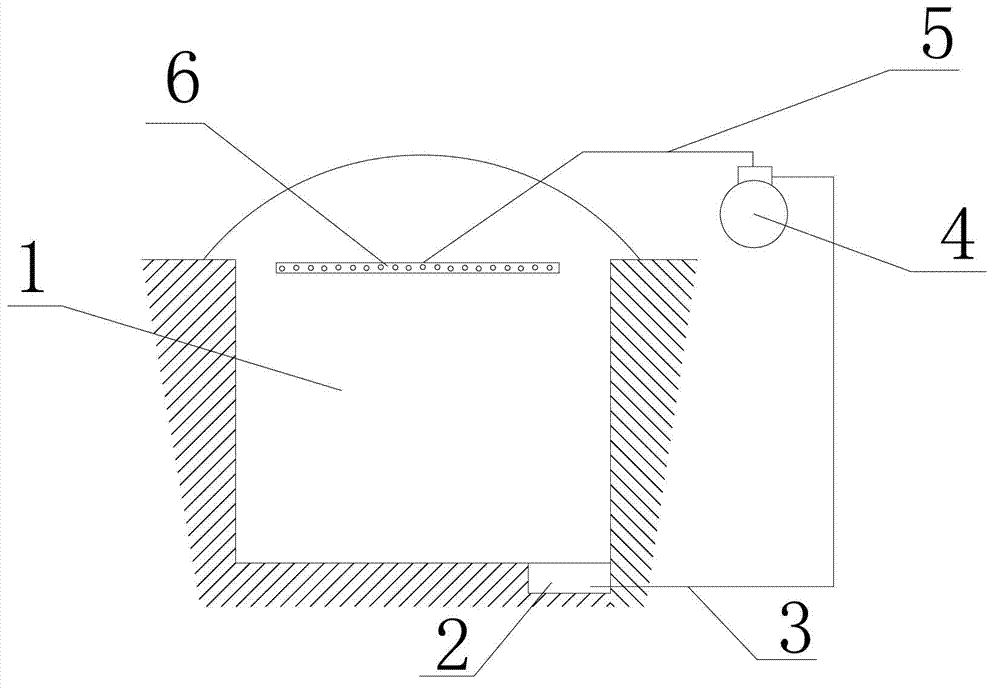

[0020] Using the method of the present invention, after 35 days of fermenting the fermented grains, the cellar yellow water circulation system of the present invention is used to make 0.05-0.1m of water per 24 hours. 3 Yellow water / bad m 3 The yellow water circulation speed is high, and the yellow water is transferred from the yellow water pit 2 at the bottom of the cellar to the top of the cellar 1 to evenly moisten the fermented grains in the upper layer, and so on until the end of the fermentation period.

[0021] The natural fermentation method of fermented grains was used as a comparison, and the cellars of the same size and quality were used, and the fermented grains of the same quality were filled into the cellars at the same time and fermented in a closed manner for 60 days.

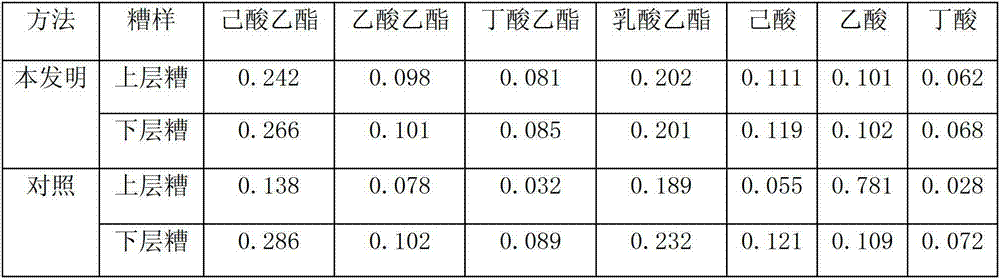

[0022] After the fermentation is over, tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com