Non-alkali composite flooding compound based on straight-chain fatty alcohol ether carboxylic betaine

A technology of non-alkali composite flooding and alcohol ether carboxyl, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems not mentioned in the application of straight-chain fatty alcohol ether carboxy betaine, and achieve the improvement of critical micelle Concentration, reduced Krafft point, good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0060] This preparation example provides N-[hexadecyl polyoxyethylene ether (3)-2-hydroxypropyl]-N, N-dimethylcarboxybetaine amphoteric surfactant, and its synthetic method comprises the following steps:

[0061] (1) Etherification reaction: Add 0.10mol n-hexadecyl alcohol polyoxyethylene ether (3), 0.005mol tetrabutylammonium bromide, 0.20mol solid NaOH into a three-necked flask equipped with electric stirring, thermometer and reflux condenser , add n-hexane as a solvent, heat up to 60°C, add 0.11mol epichlorohydrin dropwise to react at constant temperature for 4 hours, then wash with water until neutral, and obtain the etherification reaction product;

[0062] (2) Amination reaction: Add 0.05mol of the above-mentioned etherification reaction product in a three-necked flask equipped with electromagnetic stirring, a thermometer, a reflux condenser and a drying tube, 10.0g of a dimethylamine aqueous solution with a mass concentration of 30-33%, add Ethanol was used as a solvent...

preparation example 2

[0066] This preparation example provides N-[octadecyloxy-2-hydroxypropyl]-N, N-dimethylcarboxybetaine, and its synthetic method comprises the following steps:

[0067] (1) etherification reaction: add 0.10mol n-octadecyl alcohol, 0.005mol tetrabutylammonium bromide, 0.20mol solid NaOH in the there-necked flask equipped with electric stirring, thermometer and reflux condenser, add n-hexane as solvent, Heating to 50°C, adding 0.11mol epichlorohydrin dropwise to react at constant temperature for 3 hours, and then washing with water until neutral to obtain an etherification reaction product;

[0068] (2) Amination reaction: Add 0.05mol of the above-mentioned etherification reaction product in a three-necked flask equipped with electromagnetic stirring, a thermometer, a reflux condenser and a drying tube, 10.0g of a dimethylamine aqueous solution with a mass concentration of 30-33%, add Ethanol was used as a solvent, the reaction was stirred at 50°C for 1 h, and the ethanol was rem...

Embodiment 1

[0073] The N-(eicosyloxy-2-hydroxypropyl)-N,N dimethylcarboxybetaine provided in this example is prepared by the similar method of Preparation Example 2, the difference is that the preparation example 2 The reactant n-stearyl alcohol is replaced by n-eicosanol.

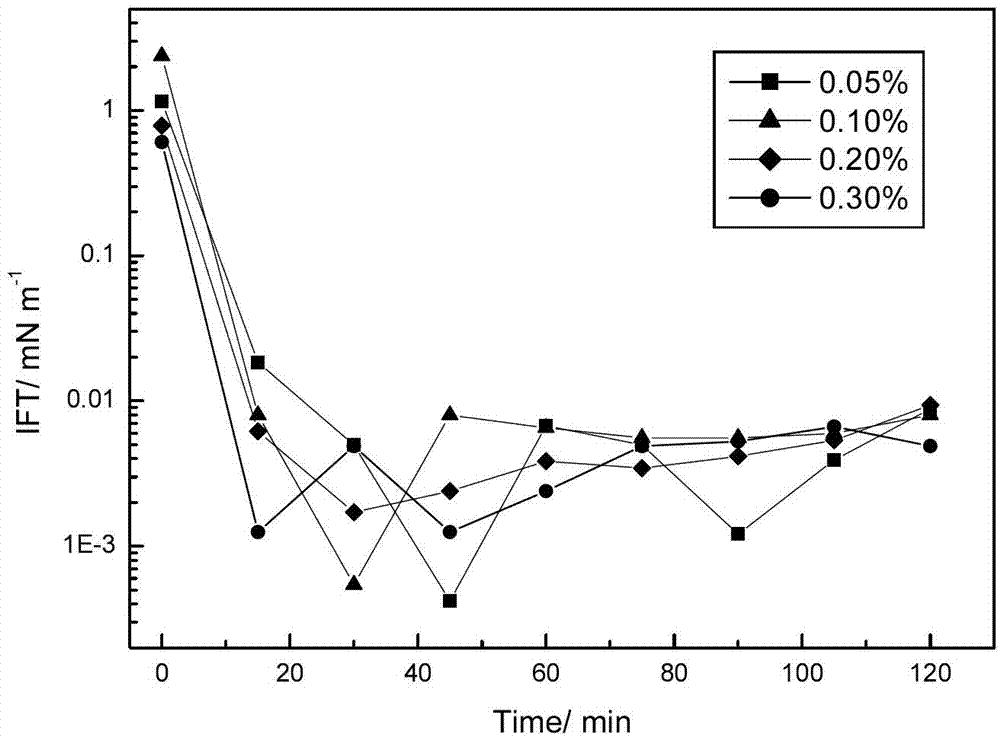

[0074] The amphoteric surface containing N-(eicosyloxy-2-hydroxypropyl)-N,N dimethylcarboxybetaine was prepared from the produced water of Daqing No. 4 Plant (its salinity and main ion content are shown in Table 1). A series of non-alkali composite flooding compositions of active agent and polymer binary system, wherein the mass concentration of surfactant is 0.05%, 0.10%, 0.20%, and 0.30% respectively; the polymer is partially hydrolyzed polyacrylamide, its The mass concentration is 0.12%. At 45°C, the interfacial tension with crude oil from Daqing No. 4 Plant was sequentially measured, and the results are as follows image 3 shown. Under the condition of no alkali and no other additives, the oil-water interfacial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com