Light diffusion plate for simultaneously raising light transmittance and haze and matching technology thereof

A technology of light diffuser and light transmittance, applied in the direction of diffusing elements, etc., can solve the problems affecting the light transmittance of the light diffuser, and the light diffuser cannot guarantee high light transmittance, etc. Excellent UV performance and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

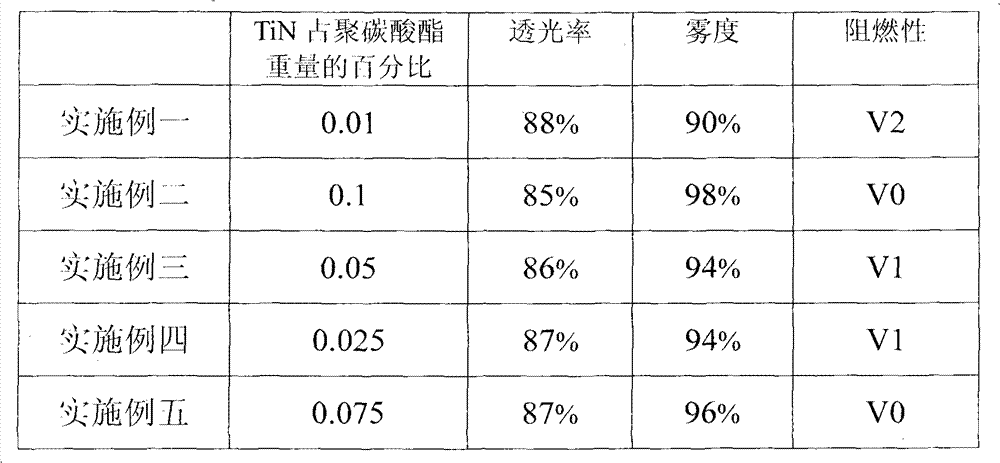

[0016] A light diffusing plate that simultaneously improves light transmittance and haze. The raw material formula components of the above light diffusing plate include a base material made of transparent resin and a light diffusing agent. The key is that the light diffusing agent is Titanium nitride, or zinc nitride, or tin nitride, or iron nitride, or copper nitride, or copper phosphide, or iron phosphide, or two or more of the above It is formed by compounding a mixture of substances, and the weight percentage of the above light diffusing agent in the transparent resin is: 0.01-5%.

[0017] The above-mentioned light diffusing agent has an average particle fineness of 1-50 nm.

[0018] The nitride of titanium mentioned above is TiN, and the nitride of zinc is Zn 3 N 2 , tin nitride is Sn 3 N 4 , Iron nitride is Fe 3 N, copper nitride is Cu 3 N, the phosphide of copper is Cu 3 P, the phosphide of iron is Fe 3 p.

[0019] The above-mentioned transparent resin comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com