Control system and method of continuous artificial plate hot press

A control system, a technology for a hot press, which is applied to sequence/logic controller program control, electrical program control, flat products, etc. The effect of convenient debugging and maintenance, high reliability and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

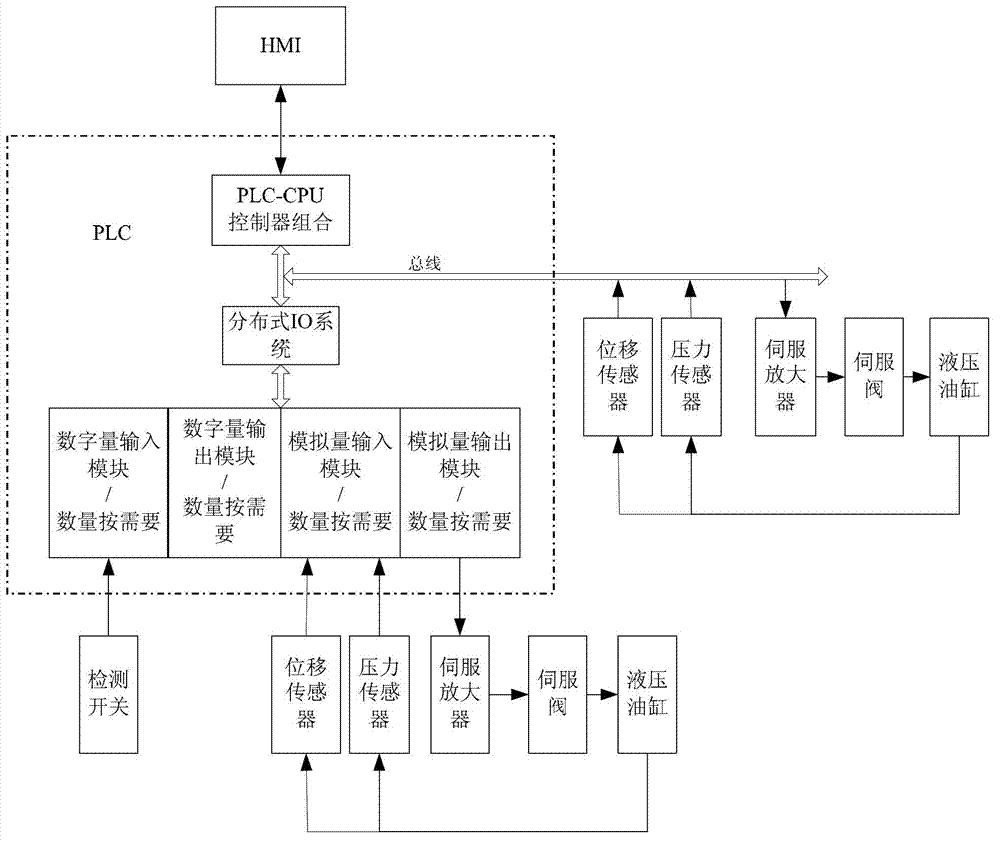

[0026] like figure 1 As shown, a wood-based panel continuous hot press control system in this embodiment includes a PLC, a hydraulic cylinder, a displacement sensor, a pressure sensor, a servo valve amplifier, a servo valve, a detection switch, a motor, and an HMI connected to the PLC for providing an HMI. (Human Machine Interface, human-machine interface) computer or touch screen, PLC includes CPU, distributed I / O system, and digital input modules, digital output modules, and analog input modules connected to the CPU through the distributed I / O system And the analog output module, the displacement sensor and the pressure sensor are connected with the PLC, the servo valve amplifier is connected with the servo valve and the PLC respectively, the detection switch is connected with the digital input module of the PLC, and is used to detect the signals of the actions of each component in the control system; The displacement sensor and the pressure sensor are respectively connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com