Horizontal feeding device of numerical control vertical lathe with maximum machining diameter of 2.5m

A CNC vertical, diameter machining technology, applied in feeding devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of complexity, high price, difficult maintenance, etc., to improve positioning accuracy and motion accuracy, and low cost of use , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

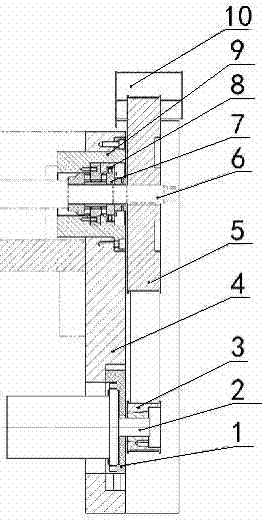

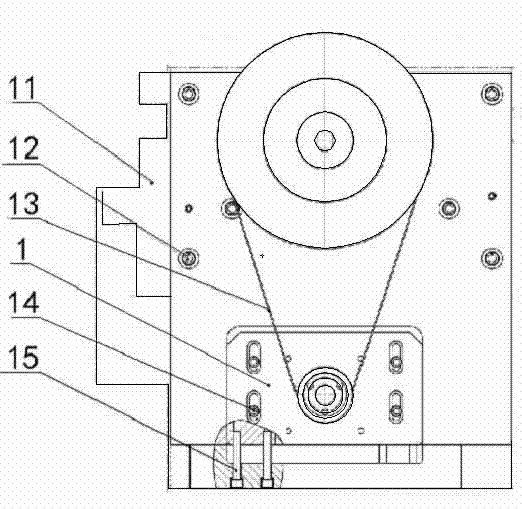

[0014] The accompanying drawings disclose the specific structure of the embodiment of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings

[0015] Depend on figure 1 , 2 It can be seen that the present invention includes a beam 11, a beam end plate 4, a servo motor 2, a synchronous belt transmission device composed of a toothed driving pulley 3, a toothed passive pulley 5 and a synchronous toothed belt 13, and leading parts such as a lead screw 6. composition. The beam end plate 4 is fixed on the end of the beam 11 by screws 12, and the servo motor 2 is installed on the distance-adjusting slide 1; after the servo motor 2 and the distance-adjusting slide 1 are fixed, the distance-adjusting slide 1 is first tightened Screw 15 adjusts the center distance between the motor shaft and the lead screw, and then fixes its position on the beam end plate 4 by locking screw 14; the lead screw 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com