Film coating agent for seedling tray and preparation and use method of film coating agent

A film-coating agent and film-forming technology, which is applied to plant protection covers, etc., can solve the problems of inability to solve the problem of film covering of seedling trays, inapplicable film covering of seedling trays, and frequent spillage and damage, so as to facilitate long-distance transportation , Improve the emergence rate, and the effect of reasonable ratio of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of film-covering agent for seedling cultivation tray of the present invention is:

[0055] Fill the container with water, pour the film-forming components into the water, stir for 3-5 minutes, then pour in the auxiliary components, continue to stir for 3-5 minutes, and then stand still for 30 minutes to obtain the present invention. Weakly acidic.

[0056] The using method of film-covering agent for seedling raising tray of the present invention is:

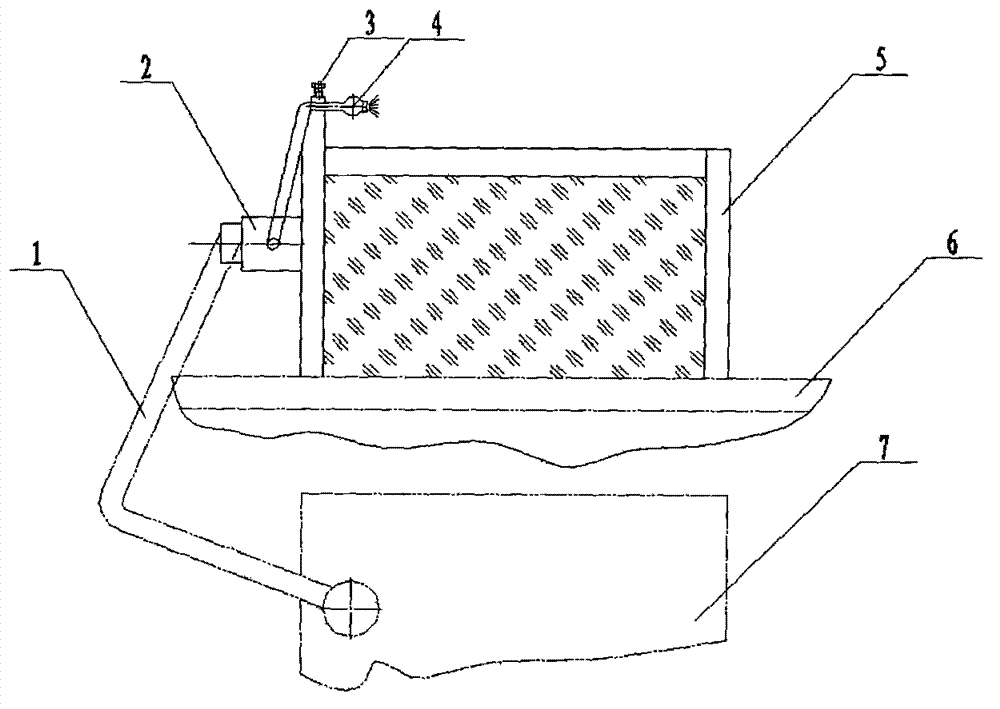

[0057] A, the coating agent that configures is packed in the water tank 7 of coating device, (as figure 1 as shown, figure 1 It is a schematic diagram of the structure of the laminating device used when inventing the lamination. ) The coating device comprises a water tank 7 and a nozzle 4, the coating device is arranged on the frame 6, the coating device is provided with a coating frame 5, and one end of the coating frame 5 is provided with a nozzle 4 and an angle adjustment bolt 3, and the nozzle...

specific Embodiment

[0080] 1. Put 10kg of water in the container, pour 1kg of biochemical potassium fulvic acid into the water, stir for 3-5 minutes, then pour 2.5g of copper sulfate, 12.5g of 75% chlorothalonil wettable powder into the water, and continue stirring 3-5 minutes, then stand still for 30 minutes to obtain the present invention. When using, the steps are as follows:

[0081] A. Put the configured coating agent into the water tank of the coating device. The coating device includes a water tank and a nozzle. The coating device is set on the frame. There are nozzles and angle adjustment bolts, the nozzles are fixed on the film frame through the angle adjustment bolts, and the angle adjustment bolts are used to adjust the spray angle of the nozzles; the bottom of the frame is equipped with a water tank and a distribution box, and a pressure pump is installed in the water tank. , There is a cut-off valve under the nozzle, and the cut-off valve is fixed on the laminating frame. Fixed con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com