Semiconductor microwave oven and semiconductor microwave generator connecting structure for same

A technology of microwave generator and connection structure, which is applied in microwave heating, household stove/stove, heating fuel, etc. It can solve the problems of long cooking time, poor heat dissipation, large transmission loss, etc., and achieve reduction of transmission loss and increase of adjustment range. Large, simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

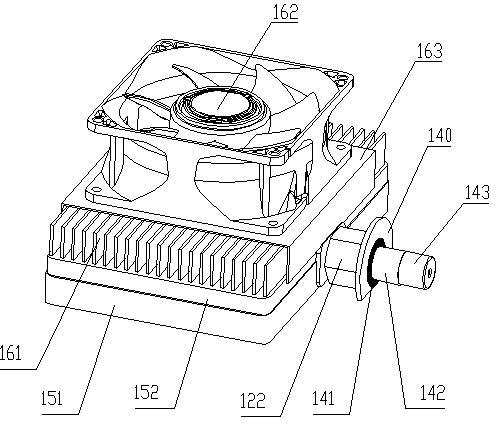

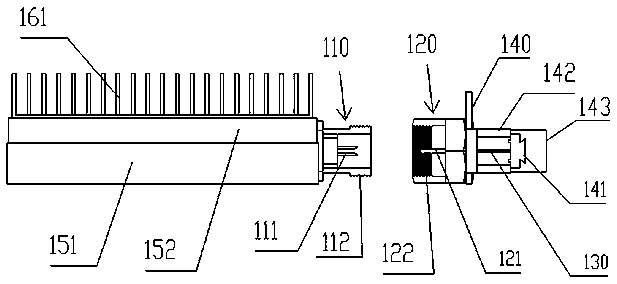

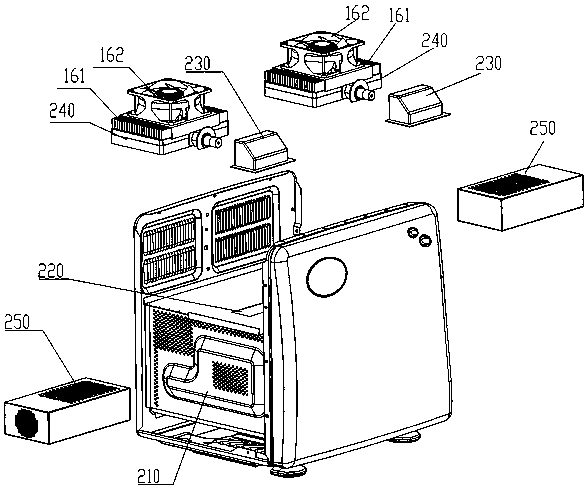

[0028] see figure 1 and figure 2 , the semiconductor microwave generator connection structure of the embodiment of the present invention, which includes a semiconductor microwave generator and an antenna 130 connected thereto, and the semiconductor microwave generator and the antenna are connected through a matching adapter socket 110 and an adapter plug 120 connected, the semiconductor microwave generator directly transmits the microwave to the antenna head 141 through the matching socket and plug, which shortens the transmission distance and reduces the loss of the microwave in the transmission process, and has a simple and compact structure and less transmission loss.

[0029] In this embodiment, the adapter socket 110 is disposed on the semiconductor microwave generator, the adapter plug 120 is disposed at one end of the antenna 130 , and the antenna head 141 is disposed at the other end of the antenna. The connection structure can also adopt another embodiment, the adap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com