Direct drive type wind turbine generator system

A wind turbine, direct-drive technology, applied in the direction of wind motor combination, wind engine, wind power generation, etc., can solve the problems that increase the difficulty of unit design, the difficulty of wind farm construction, large volume and weight, and excessive motor volume and weight. , to achieve the effect of improving economy and reliability, reducing weight and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

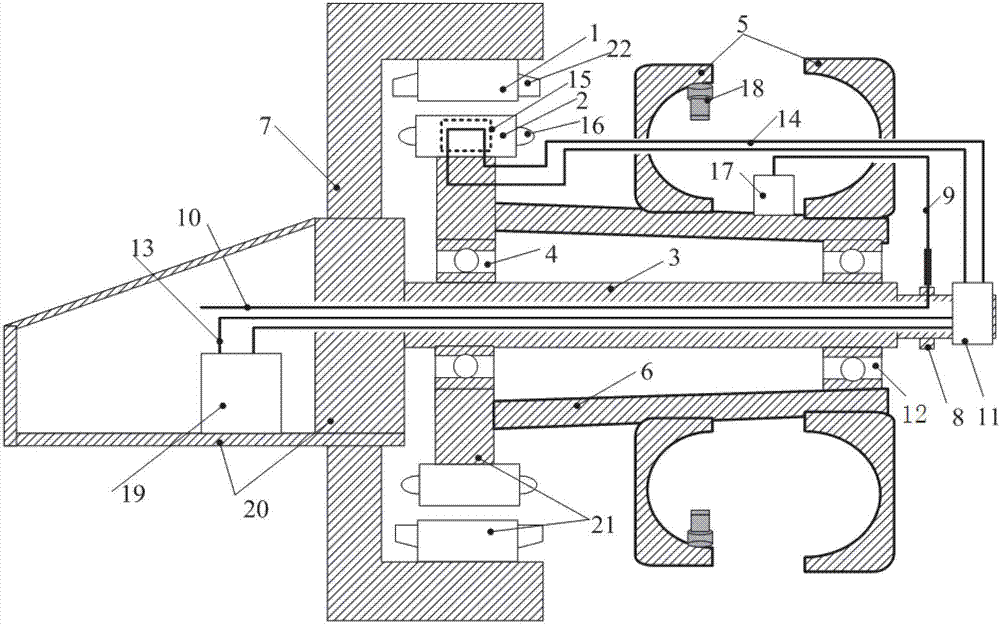

[0019] see figure 1 As shown, a direct-drive wind power generating set of the present invention includes a frame 20, a main shaft 3, a hub 5 and a generator 21, wherein the generator 21 adopts a high-temperature superconducting generator, that is, its rotor 2 adopts a superconducting excitation coil 16 Excite the motor.

[0020] The rotor 2 of the generator 21 of the present invention can be fixedly connected with the hub 5 through the rotor bracket 6, and the rotor bracket 6 is rotatably supported on the main shaft 3, so that the rotor 2 and the hub 5 can rotate around the main shaft 3 at the same speed. Preferably, the present invention adopts a double bearing la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com