Micro-display slit system and micro-display slit method

A microscopic and fissure technology, applied in microscopes, optics, instruments, etc., can solve the problems of difficult adjustment, complex overall structure, and high manufacturing cost, and achieve the effect of simplified overall structure, simple adjustment operation, and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiment of the present invention will be further elaborated below in conjunction with accompanying drawing:

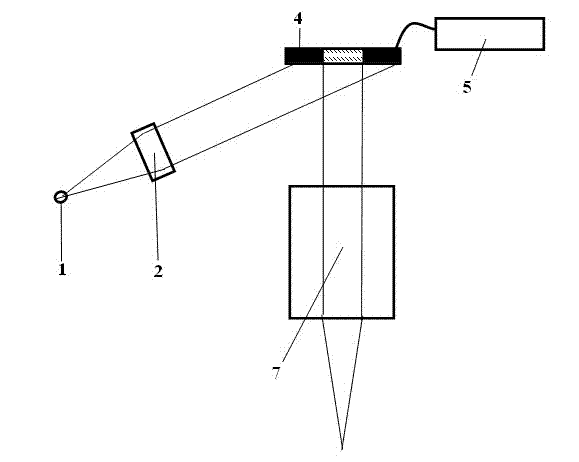

[0035] figure 1 It is a schematic diagram of a digital light processing DLP chip micro-crack implementation system. The micro-display chip 4 uses a digital light processing DLP chip, and the micro-display chip drive unit 5 controls and forms cracks on the micro-display chip 4 . The light emitted by the light source 1 reaches the microdisplay chip 4 after passing through the collimation unit 2, and the array of tiny mirrors in the slit actually becomes a surface light source irradiated by parallel light, and each tiny mirror on it The angle can be controlled by the micro-display chip driving unit 5; the reflection direction of the tiny mirror array of the micro-display chip 4 is controlled by the micro-display chip driving unit 5 to achieve control of whether and how much light passes through the projection unit 7, different crack patterns ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com