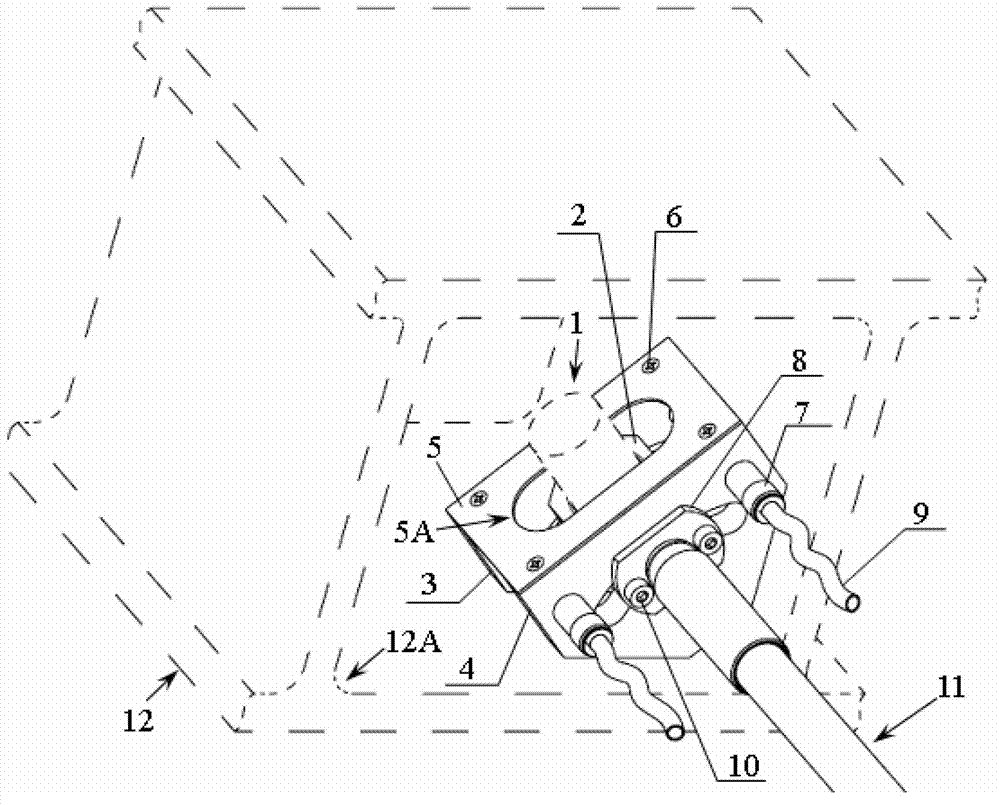

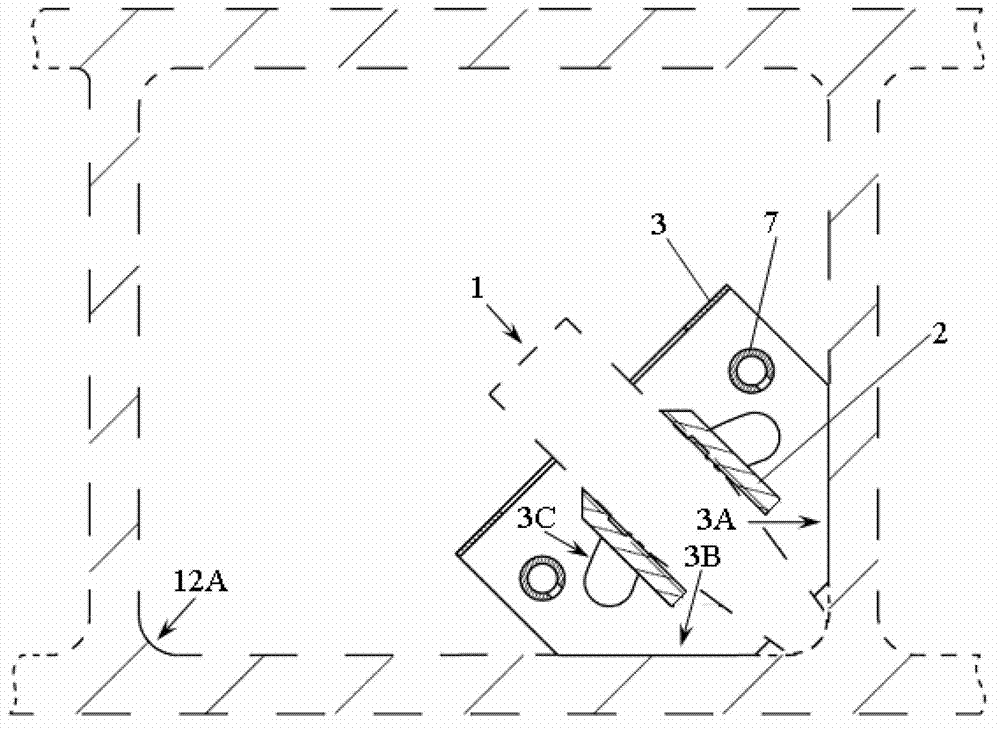

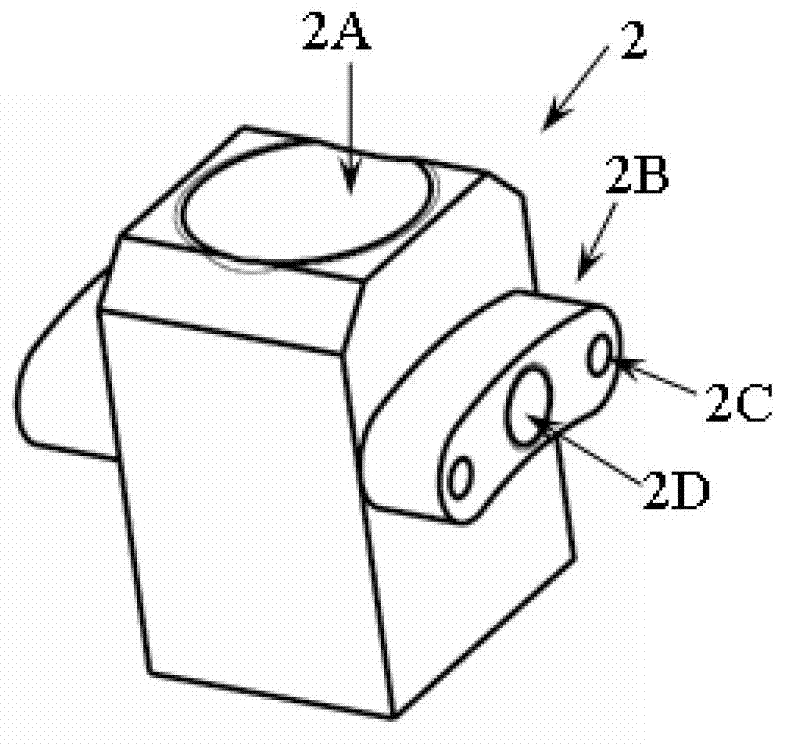

Ultrasonic scanning device and method for detecting R region of inner cavity of composite material structure

A composite material and scanner technology, which is applied in the analysis of materials, the analysis of solids using sonic/ultrasonic/infrasonic waves, and the material analysis using sonic/ultrasonic/infrasonic waves, which can solve missed detection and misjudgment, influence discrimination and qualitative analysis , the signal law is not clear and other problems, to improve the stability and reliability, improve the stability of the detection signal, improve the effect of sound wave coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Adopt the ultrasonic probe in the closed inner cavity R region of the detection composite material structure in the present invention, select FCC-B-1, FCC-D-1 and MUT-1 in the FCC and MUT series ultrasonic instruments produced by Beijing Aeronautical Manufacturing Engineering Research Institute. Two types of ultrasonic instruments are respectively matched with the ultrasonic scanner in this patent invention, and the composite material structure closed inner cavity R area ultrasonic scanning detection method in the present invention is used to composite the aircraft with a length between 1000-2800mm respectively. A series of actual ultrasonic scanning tests were carried out on the R area of the closed inner cavity of the overall structure of the material. During the scanning process, the ultrasonic probe was always in good contact with the surface of the R area of the inner cavity of the overall structure of the composite material to be tested, and the detection signal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com