Synthesis method of hydroxylated polyvinyl chloride copolymer resin

A technology of polyvinyl chloride copolymer resin and synthesis method, which is applied in the field of emulsion copolymerization to introduce HEMA into PVC chains, which can solve the problem of low HEMA content (not exceeding 0.1%, difficult cost of monomer and resin separation and recovery, HEMA homopolymerization ratio Large and other problems, to achieve the effect of large particle size range of latex, less pollution, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The composite emulsifier, initiator I, desalinated water, pH regulator, seed emulsion and vinyl chloride monomer are polymerized under anaerobic and closed conditions. The polymerization temperature is 50°C. The polymerization time of initiator II and HEMA monomer is 12 hours to prepare copolymer emulsion; then recover the unreacted vinyl chloride monomer to obtain colloidal particles with an average particle size greater than 1.0 μm. After spray drying, vinyl chloride / hydroxyethyl methacrylate copolymer paste resin is obtained.

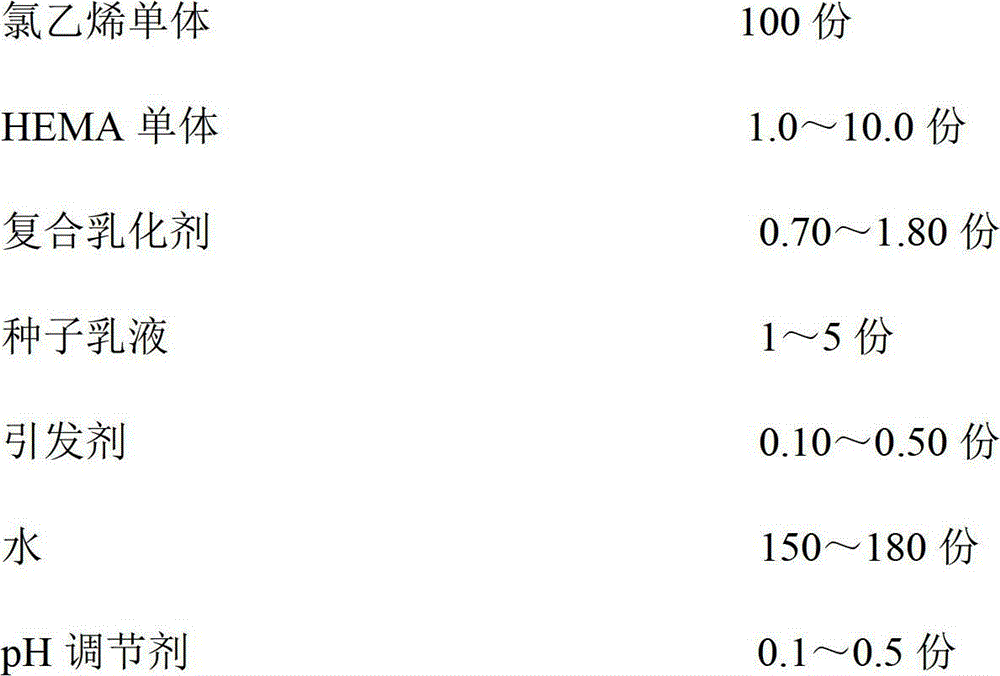

[0031] The parts by weight of each component are as follows:

[0032]

[0033]

[0034] The seed emulsion particle diameter is 120nm, and the weight solid content is 42%;

[0035] The composite emulsifier is a mixture of sodium dodecylbenzenesulfonate and myristyl alcohol, and the weight ratio is 2:1;

[0036] The initiator I is ammonium persulfate, the initiator II is tert-butyl hydroperoxide, and the weight ratio of the initiator I t...

Embodiment 2

[0040] The composite emulsifier, initiator I, desalinated water, pH regulator, seed emulsion and vinyl chloride monomer are polymerized under anaerobic and closed conditions. The polymerization temperature is 52°C. Initiator II and HEMA monomer are polymerized for 10 hours to obtain a copolymer emulsion; then unreacted vinyl chloride monomer is recovered to obtain colloidal particles with an average particle size greater than 1.5 μm. After spray drying, vinyl chloride / hydroxyethyl methacrylate copolymer paste resin is obtained.

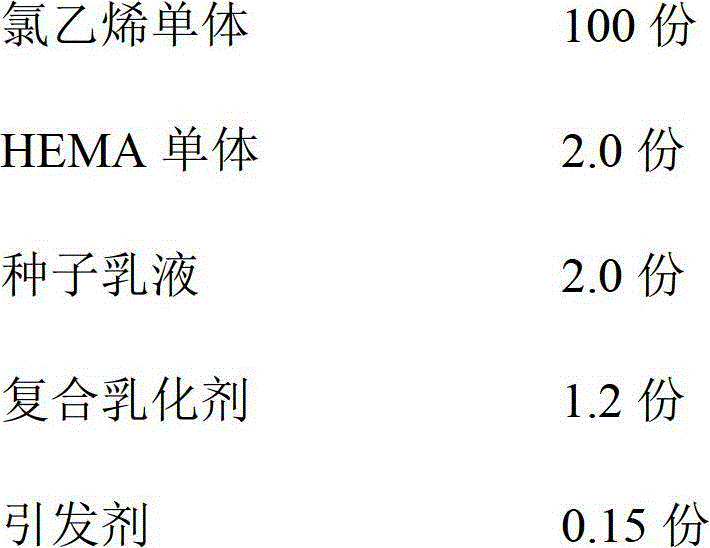

[0041] The parts by weight of each component are as follows:

[0042]

[0043] The particle size of the seed emulsion is 300nm, and the weight solid content is 32%; the compound emulsifier is a mixture of sodium dodecylsulfonate and cetyl alcohol, and the weight ratio is 1.8:1;

[0044] The initiator I is potassium persulfate, the initiator II is diethylhexyl peroxydicarbonate, and the weight ratio of the initiator I to the initiator II is 4:1;

...

Embodiment 3

[0048] The composite emulsifier, initiator I, desalinated water, pH regulator, seed emulsion and vinyl chloride monomer are polymerized under anaerobic and closed conditions. The polymerization temperature is 55°C. Initiator II and HEMA monomer, the polymerization time is 9h, and the copolymer emulsion is prepared; then the unreacted vinyl chloride monomer is recovered, and the colloidal particles with an average particle size greater than 1.6 μm can be obtained. After spray drying, vinyl chloride / hydroxyethyl methacrylate copolymer paste resin is obtained.

[0049] The parts by weight of each component are as follows:

[0050]

[0051] The particle size of the seed emulsion is 210nm, and the weight solid content is 35%; the composite emulsifier is a mixture of nonyl aryl polyether alcohol and octadecanoic acid, and the weight ratio is 1:1;

[0052] The initiator I is a mixture of sodium bisulfite and copper sulfate with a mass ratio of 1:0.1, and the initiator II is dieth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com