Gas phase acid catalytic biomass hydrolysis continuous production method of furfural

An acid catalysis and biomass technology, applied in the direction of organic chemistry, etc., can solve the problems of difficult treatment of acid-containing waste residue, low furfural content, and many side reactions, and achieve the effects of less side reactions, high furfural yield, and less discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

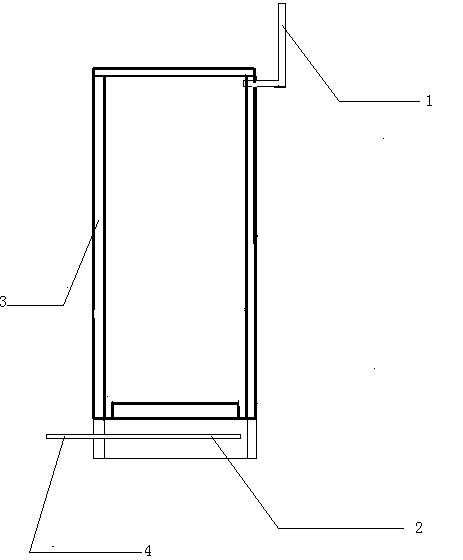

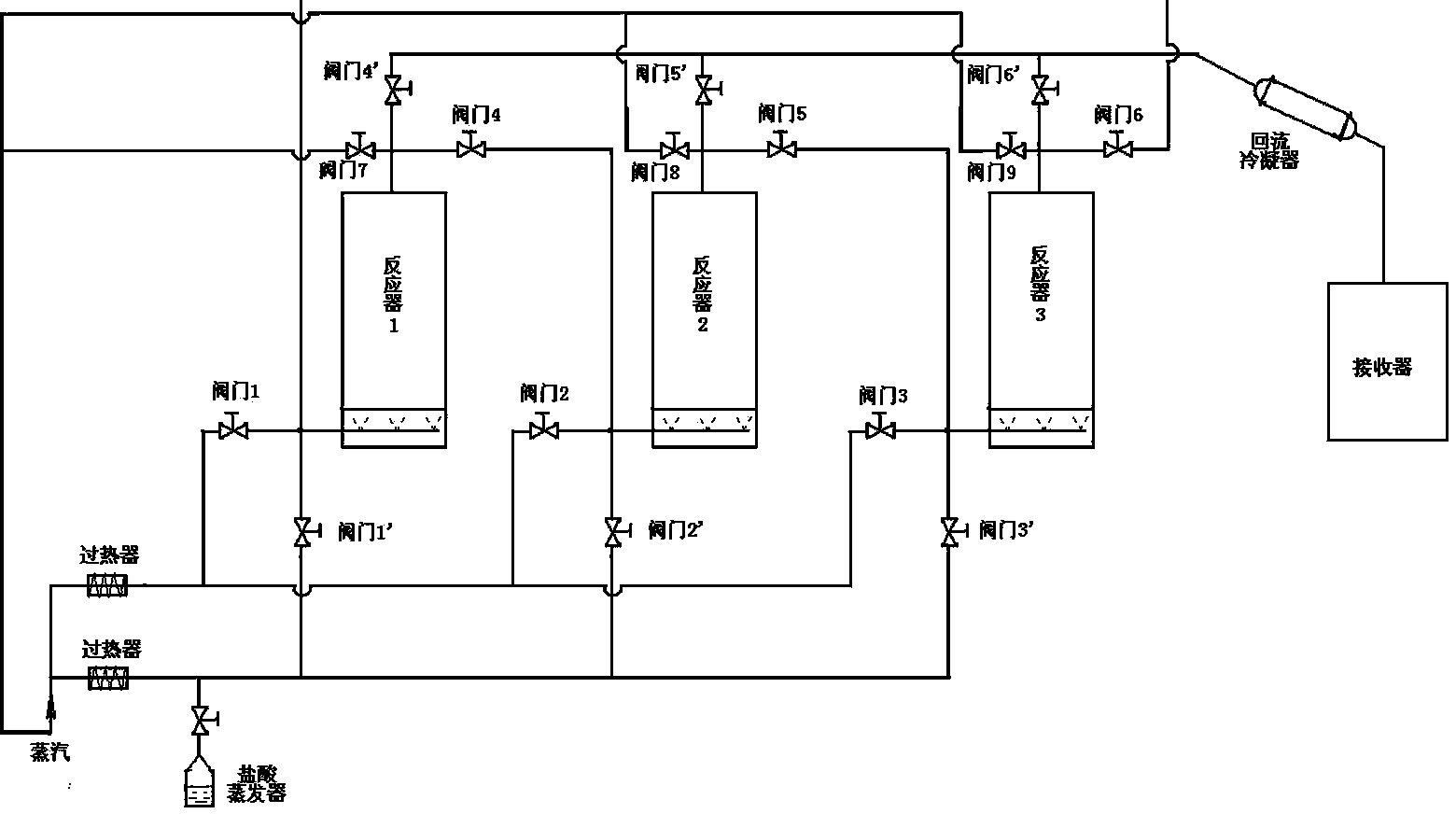

Image

Examples

Embodiment 1

[0030] The diameter-to-height ratio of the reactor is 1:100, the amount of straw in a single reactor is 1500g, the total amount of straw in one cycle is 4500g, the mass concentration of hydrochloric acid is 5%, the steam flow rate is 15 mL / min, and the temperature in the reactor is 165 o C, according to the above operation steps, when the concentration of furfural at the outlet of reactor 3 is reduced to below 0.1%, 20.2 kg of furfural aqueous solution with a content of 1.4% is obtained, and the yield is 40%.

Embodiment 2

[0032] The ratio of diameter to height of the reactor is 1:100, the amount of straw in a single reactor is 1500g, the total amount of straw in one cycle is 4500g, the mass concentration of hydrochloric acid is 5%, the steam flow rate is 30 mL / min, and the temperature in the reactor is 155 o C, according to the above operation steps, when the concentration of furfural at the outlet of reactor 3 is reduced to below 0.1%, 15.2 kg of furfural aqueous solution with a content of 2.8% is obtained, and the yield is 60.2%.

Embodiment 3

[0034] The ratio of diameter to height of the reactor is 1:100, the amount of straw in a single reactor is 1500g, the total amount of straw in one cycle is 4500g, the mass concentration of hydrochloric acid is 5%, the steam flow rate is 25 mL / min, and the temperature in the reactor is 145 o C, according to the above operation steps, when the concentration of furfural at the outlet of reactor 3 is reduced to below 0.1%, 8.0 kg of furfural aqueous solution with a content of 8% is obtained, and the yield is 90.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com