Gumming method of continuous fiber-woven pultrusion tubes

A continuous fiber and fiber braided layer technology, applied in the field of impregnation of fiber braided reinforced resin pipes, can solve the problems that fiber pipes cannot be pre-impregnated with monofilament, pre-impregnated with single fibers, and difficult impregnation methods, etc., to achieve The effect of high strength, firm bonding and high surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

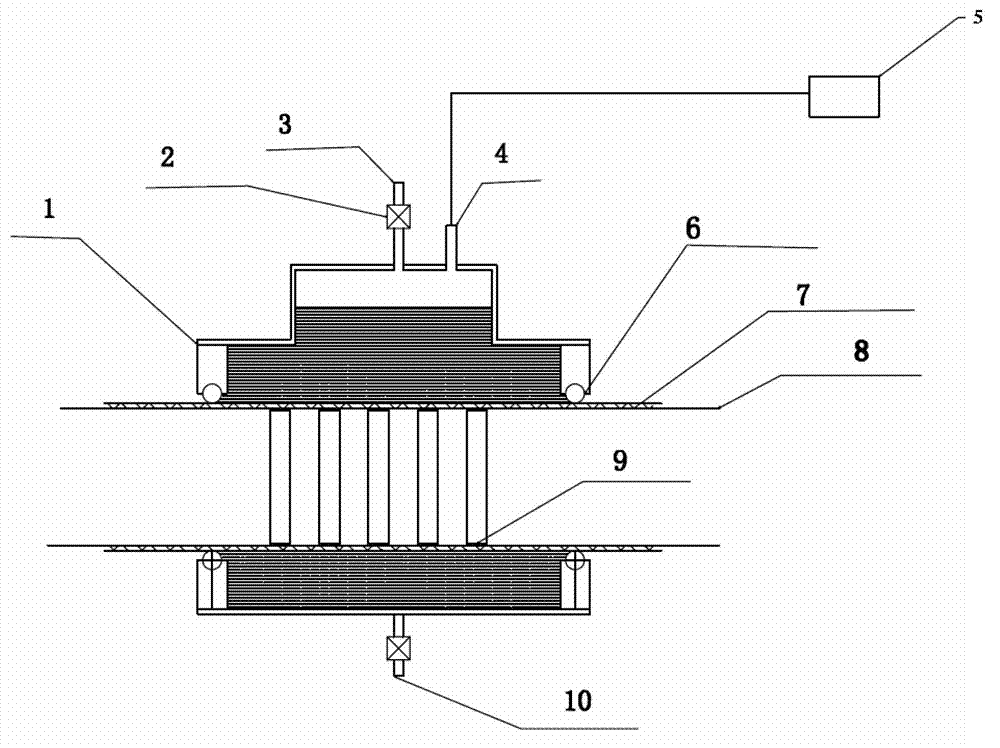

[0010] The following combination figure 1 The dipping system schematic diagram, the present invention is described for further operation, adopts vacuum technology to be very clear to the people of this specialty.

[0011] 1. Reference figure 1 , weaving the fiber layer (7) on the surface of various product molds (8);

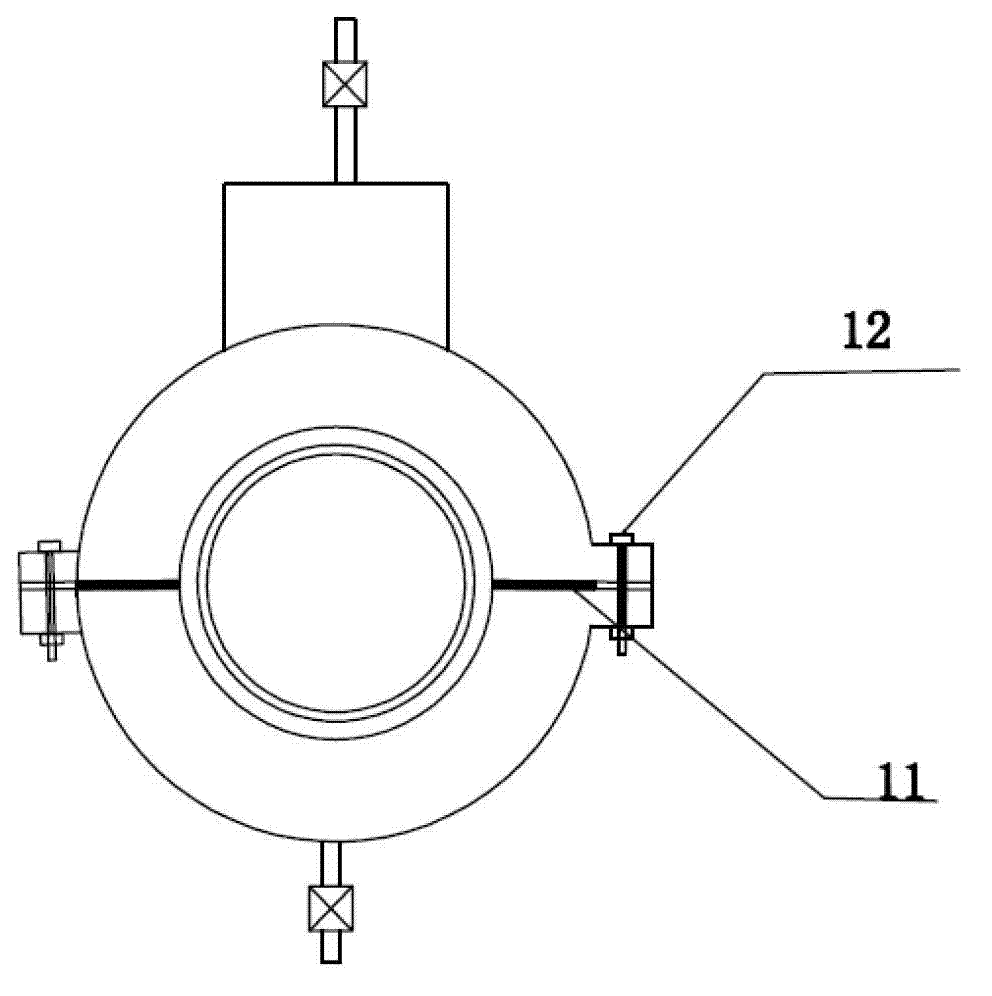

[0012] 2. Lock the two semi-cylinders of the vacuum box (1) with bolts (12), and add a sealing strip (11) and a circumferential sealing ring (6) to form a sealing system;

[0013] 3. Open the valve (2), let the resin enter the vacuum box (1) through the feed port (3);

[0014] 4. When the resin material reaches a certain amount, close the valve (2), start the vacuum pump (5), and start vacuuming.

[0015] 5. Start the main machine, the fiber layer (7) starts to move, the fiber layer has been dipped in glue, and enters the next process;

[0016] 6. When the resin is consumed to a certain extent, open the valve (2) to replenish the resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com