Numerical control spherical roller grinding machine

A technology of spherical rollers and grinding machines, which is applied in the direction of spherical grinding machines, grinding machines, and parts of grinding machine tools, and can solve problems such as low precision and shaking of the bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

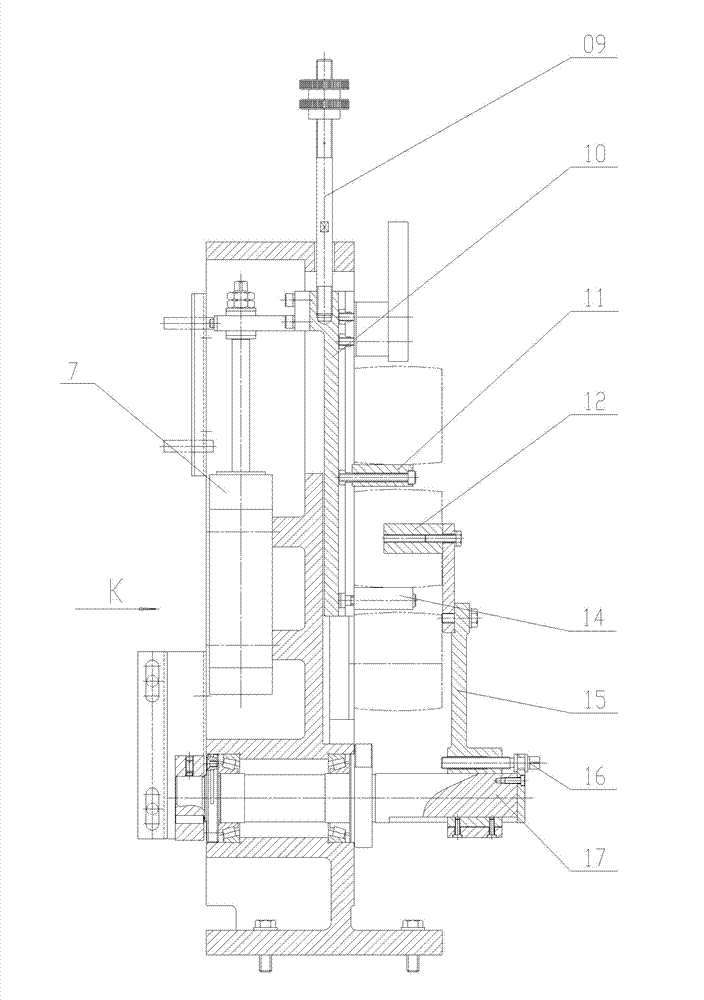

[0016] See figure 1 , which includes a bed 23, a motor 24, the motor 24 is supported on a motor base 25, the motor base 25 is located outside the bed 23, and the output end of the motor 24 is connected to the input end of the dynamic pressure grinding wheel spindle 32. The bed 23 is equipped with a workpiece shaft rotation mechanism 26, a centerless fixture and an electromagnetic chuck 27, a workpiece feeding mechanism 28, an automatic loading and unloading mechanism 29, a workpiece drive shaft 30, and a grinding wheel (not shown in the figure, which belongs to the existing mature structure) , grinding wheel cover 31, dynamic pressure grinding wheel spindle 32, single point dresser 33, dresser axial feed mechanism 34, dresser compensation feed mechanism 35, workpiece feed mechanism 28 supported on bed 23, workpiece rotary mechanism 26 Supported on the workpiece feed mechanism 28, the workpiece drive shaft 30 is connected to the base of the workpiece feed mechanism 28, the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com