Formed cutter

A technology for forming milling cutters and cutterheads, which is applied in the direction of forming cutters, milling cutters, milling machine equipment, etc., can solve the problems of small cutting area, consuming a lot of man-hours, and low processing accuracy, so as to improve work efficiency, ensure product quality, and improve The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

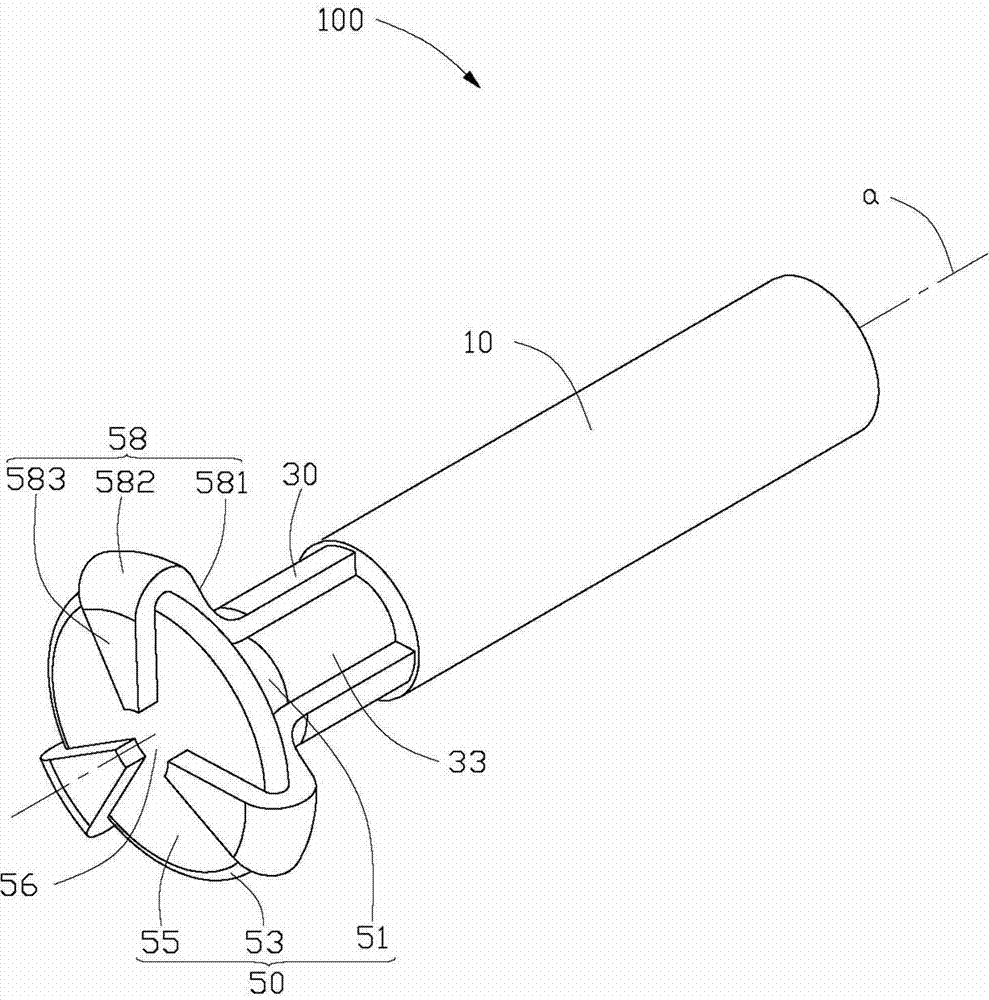

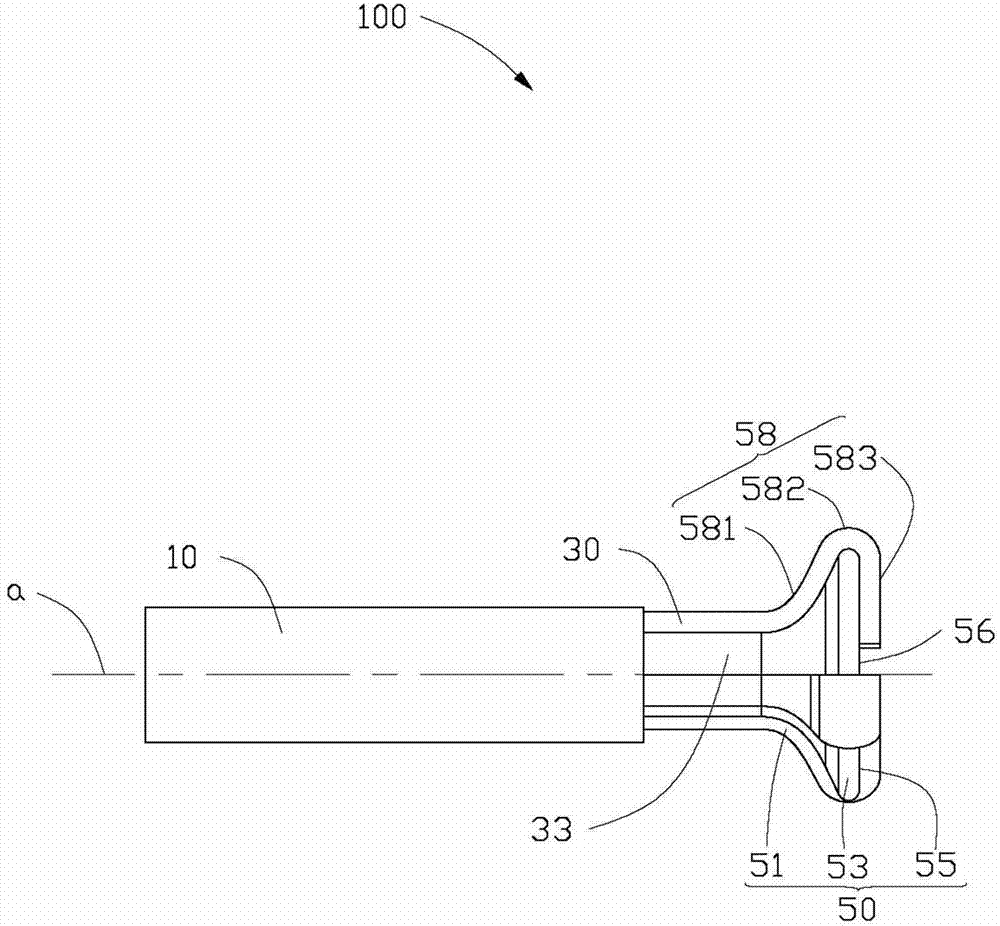

[0015] See figure 1 versus figure 2 , The forming milling cutter 100 according to the embodiment of the present invention includes a shank 10, a neck 30, and a cutter head 50 formed at the end of the neck 30. The knife handle 10 is rod-shaped, and the knife neck 30 is provided at one end of the knife handle 10 and is located between the knife head 50 and the knife handle 10. The cutter head 50 is arranged at the end of the knife neck 30 and is connected to the knife handle 10 through the knife neck 30 as a whole.

[0016] The tool holder 10 can be of a straight shank type, a tapered shank type, a crank type, etc., to facilitate clamping the forming milling cutter 100 to a driving device such as a machine tool driving shaft (not shown). In this embodiment, the tool holder 10 has a substantially cylindrical shaft shape. The tool holder 10 has a rotation axis a. During processing, the forming milling cutter 100 is driven to rotate around the rotation axis a of the tool holder 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com