Blowing and refining device and method used for removing tundish molten steel inclusion

The technology of a refining device and a blowing device is applied in the field of improving the flow of molten steel in the tundish and protecting the molten steel from being oxidized, which can solve the problems of secondary oxidation of molten steel, limited ability to capture and remove inclusions, etc. Effect of secondary oxidation and slag entrainment, prolongation of average residence time, improvement of molten steel flow behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

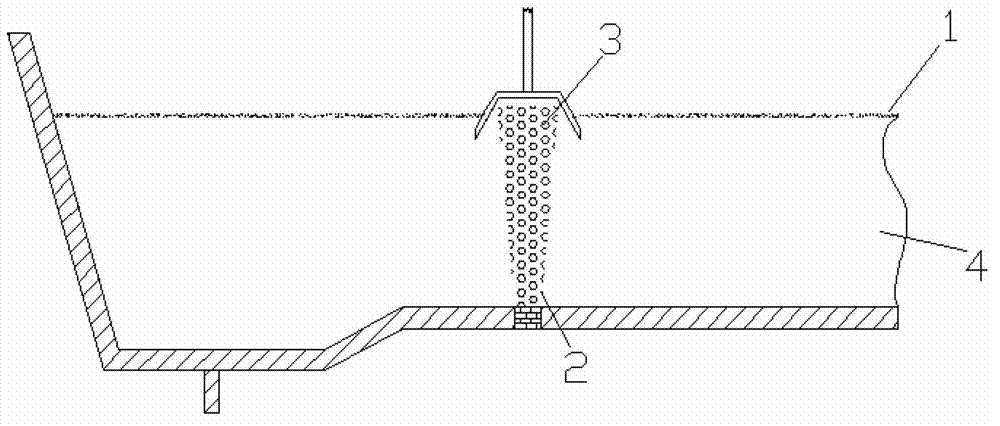

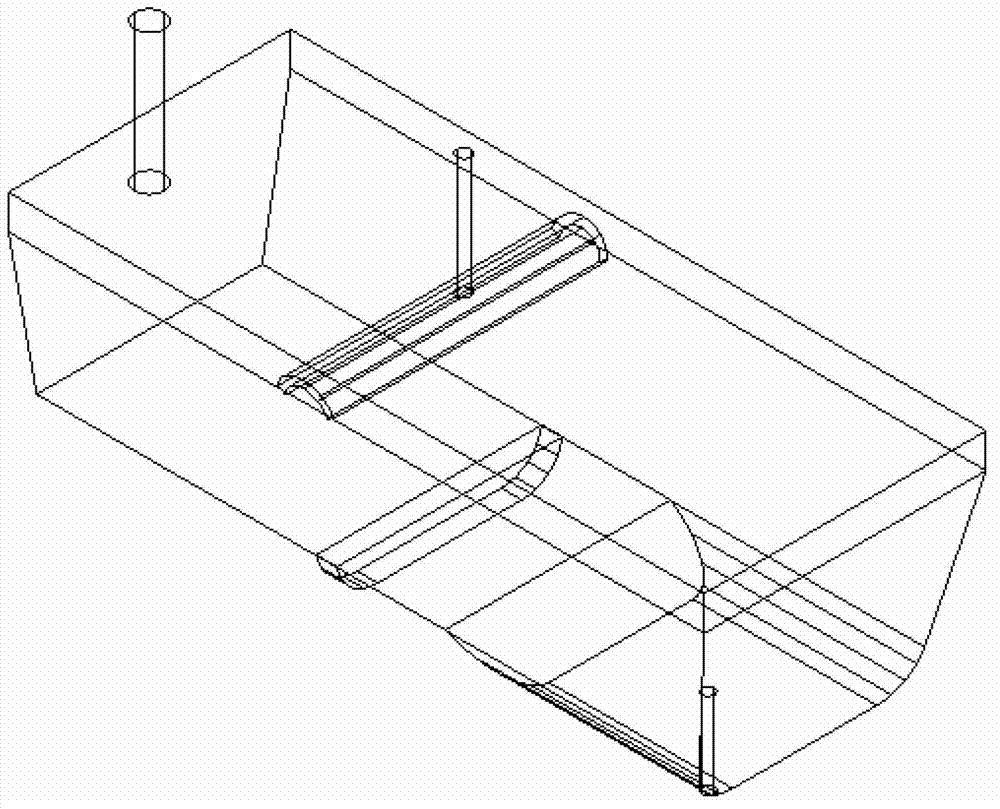

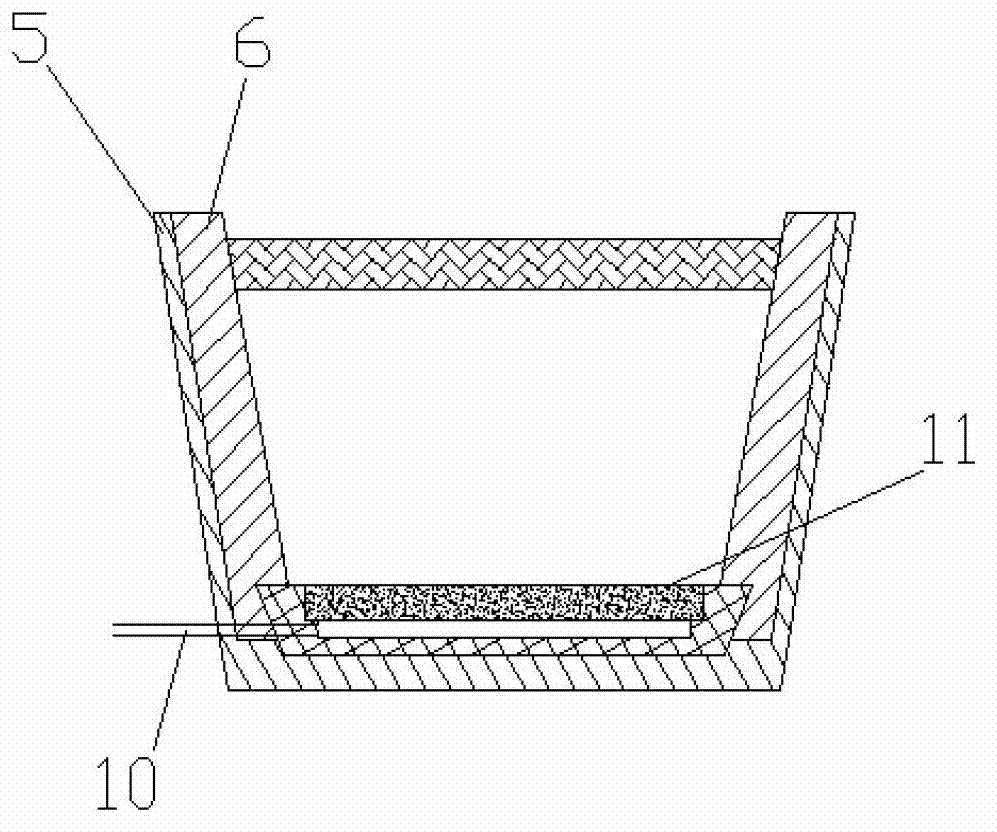

[0019] Such as figure 1 As shown, the overall structure diagram of the tundish gas blowing refining device of the present invention, the gas blowing refining device suitable for removing tundish molten steel inclusions in the present invention includes a tundish 1, a gas blowing device 2 and an impregnation cover 3, the tundish It includes a permanent layer 5 and a working layer 6 arranged on the inner surface of the permanent layer. The bottom of the permanent layer is provided with an air blowing device 2. The air blowing device includes a ventilation brick 11 and a ventilation pipe 10. The ventilation brick includes a dense Layer 7 and air-permeable layer 8. There is an air chamber 9 in the middle of the air-permeable layer. External air is blown into the air chamber through the air pipe. The impregnation cover 3 is a refractory material cover supported by a steel plate. It is composed of the immersion part 13, is provided with an exhaust hole 15, is connected with the auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com