High-Al2O3 content high-aluminum steel continuous casting slag powder

A technology for continuous casting mold powder and high-aluminum steel, which is applied in the field of mold mold powder for continuous casting of high-alumina steel and mold powder for continuous casting of high-alumina steel slabs, and can solve the problems of poor glass morphology, increased melting temperature of mold powder, Unfavorable problems such as mold flux melting and casting billet lubrication, to achieve the effect of inhibiting content, reducing reaction, mold flux composition and performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] a high Al 2 o 3 The content of high-alumina steel continuous casting mold flux, its composition mass percentage is: CaO: 7%, BaO: 14.5%, Al 2 o 3 : 31%, B 2 o 3 : 8%, SiO 2 : 5%, flux: CaF 2 : 11.3%, Na 2 O: 12.8%, Li 2 O: 1.5%, MnO: 2.5%, C: 5%, and the rest are unavoidable impurities. The melting temperature of the mold flux is 988°C, the viscosity at 1300°C is 0.24 Pa.s, and the vitrification rate is 95%.

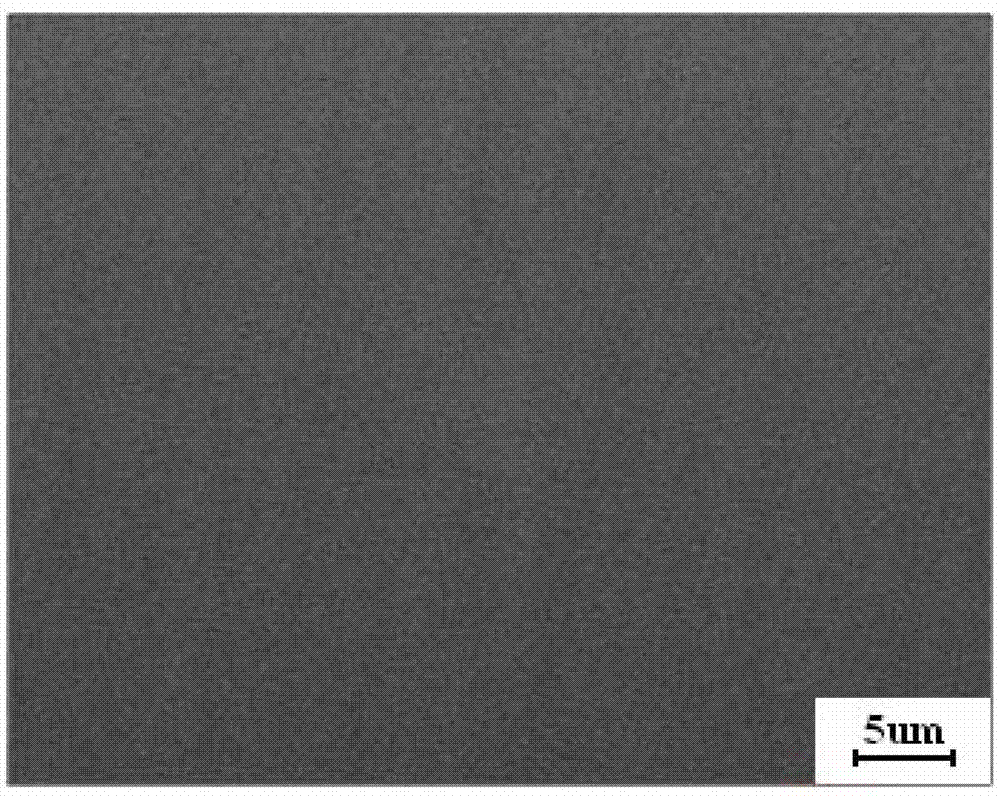

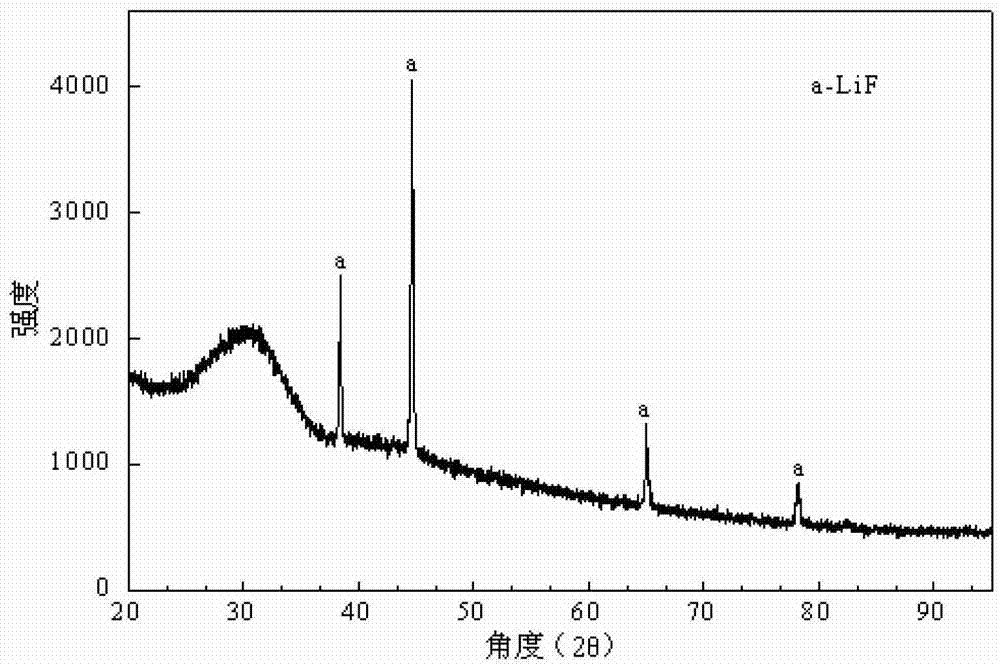

[0031] in, figure 1 High Al for this example 2 o 3 Scanning electron microscopy (SEM) of mold flux for continuous casting of high-alumina steel, figure 2 High Al for this example 2 o 3 X-ray diffraction pattern (XRD) of mold flux for continuous casting of high aluminum content steel. Depend on figure 1 It can be seen that the mold flux is mainly a single homogeneous phase; figure 2 It can be seen from the XRD analysis that the mold flux is mainly glassy and contains a small amount of LiF crystal phase.

Embodiment 2

[0033] a high Al 2 o 3 The content of high-alumina steel continuous casting mold flux, its composition mass percentage is: CaO: 8.5%, BaO: 18%, Al 2 o 3 : 25.5%, B 2 o 3 : 7.3%, SiO 2 : 4.8%, Flux: CaF 2 : 9%, Na 2 O: 12.7%, Li 2 O: 1.5%, MnO: 2%, C: 8.4%, and the rest are unavoidable impurities. The melting temperature of the mold flux is 1020°C, the viscosity at 1300°C is 0.20 Pa.s, and the vitrification rate is 90%.

Embodiment 3

[0035] a high Al 2 o 3 The content of high-alumina steel continuous casting mold flux, its composition mass percentage is: CaO: 9%, BaO: 13.5%, Al 2 o 3 : 33%, B 2 o 3 : 10%, SiO 2 : 4.2%, Flux: CaF 2 : 8.5%, Na 2 O: 9.3%, Li 2 O: 2.5%, MnO: 3.4%, C: 6%, and the rest are unavoidable impurities. The melting temperature of the mold flux is 1070°C, the viscosity at 1300°C is 0.30 Pa.s, and the vitrification rate is 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com