Combined technique of separating and recycling VOCS (volatile organic compounds) from industrial waste gas by adsorption-desorption-rectification-pervaporation

A technology for industrial waste gas and pervaporation, which is applied in the separation/purification of hydroxyl compounds, separation methods, and dispersed particle separation. It can solve the problems of large equipment investment and high energy consumption, and achieve large equipment investment, large energy consumption and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

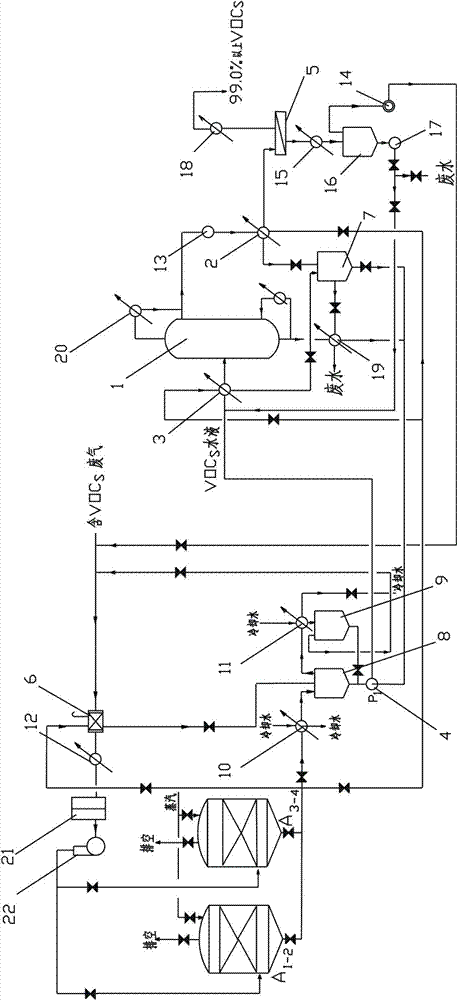

Image

Examples

Embodiment 1

[0024] Industrial wet exhaust gas of isopropanol, flow rate 15000m 3 / h, temperature 50°C, after cooling, drying and filtering, dry waste gas containing isopropanol at room temperature without suspended solids is sent to four GAC or ACF adsorption-desorber groups with high-pressure centrifugal blower, of which The two are in the state of adsorption, and the isopropanol in the exhaust gas is absorbed by it, and the purification reaches the national exhaust gas emptying standard, and then it is emptied. After GAC or ACF is saturated with isopropanol, the adsorber is switched to desorption operation, and saturated steam with a pressure of 0.15-0.20 Mpa is evenly sprayed into it from the top, GAC or ACF is heated, and the adsorbed isopropanol is desorbed at the same time. After the attachment is completed, go to the next adsorption, and so on. It contains a large amount of latent heat and sensible heat, isopropanol-containing steam-saturated water vapor, and its heat energy fract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com