Gas-liquid separator combining centrifugal separation, baffle flow direction change and porous medium filtration

A gas-liquid separator and porous media technology, applied in separation methods, dispersed particle separation, combined devices, etc., can solve the problems of high pressure drop, difficult to effectively improve the separation degree, and no efficient combination of gas-liquid separators, etc. The effect of meeting the separation requirements and having a simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

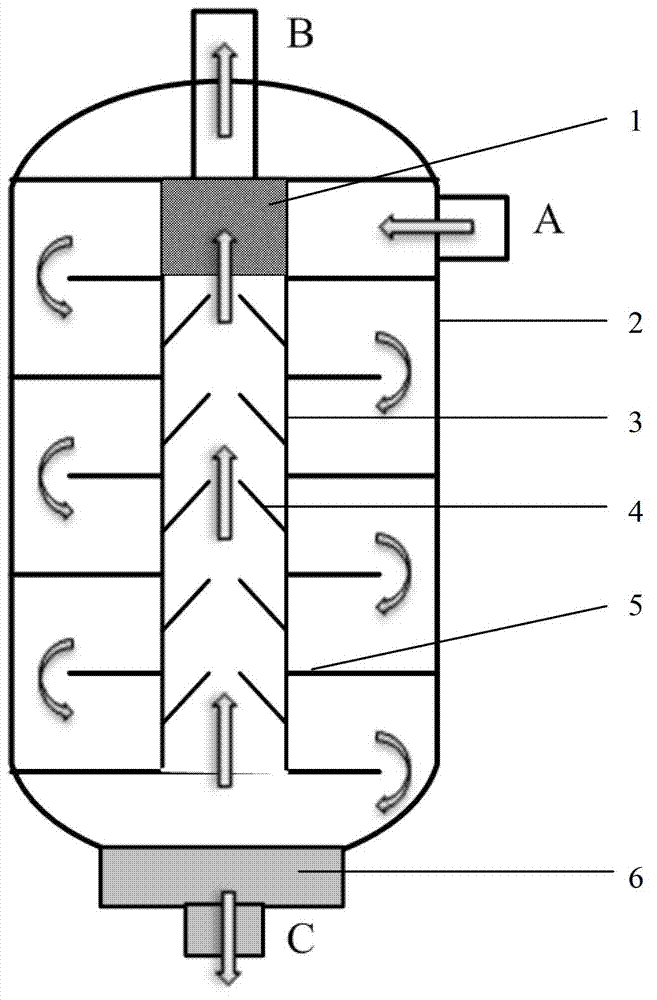

[0023] The upper and lower ends of the cylindrical separator housing 2 (diameter of 40 centimeters and height of 1 meter) placed vertically in the axial direction of this embodiment are respectively equipped with a top cover and a bottom oil collection chamber 6; 4 horizontal baffles 5 on the inner wall of the body 2 are staggered; To the center; a hollow cylindrical cavity 3 is installed in the axial center of the cylindrical separator housing 2, and the hollow cylindrical cavity 3 passes through each horizontal baffle plate 5 in turn, and the vertical inner wall of the hollow cylindrical cavity 3 5 conical baffle plates 4 with upper openings distributed up and down are installed on the top; a cylindrical adsorption filter 1 is installed on the upper end of the hollow cylindrical cavity 3; one side of the upper part of the cylindrical separator housing 2 is provided with The mixed gas inlet A connected to it; the top of the cylindrical separator housing 2 is provided with the...

Embodiment 2

[0026] The upper end and the lower end of the cylindrical separator housing 2 (60 cm in diameter and 1.5 m in height) placed vertically in the axial direction of this embodiment are equipped with a top cover and a bottom oil collection chamber 6 respectively; 20 horizontal baffles 5 on the inner wall of the cylindrical separator housing 2 are placed in a staggered manner; the horizontal baffles 5 are located below the top cover of the cylindrical separator housing, and the outer edges of the horizontal baffles 5 exceed the cylinder The radial center of the separator housing 2; a hollow cylindrical cavity 3 is installed in the center of the cylindrical separator housing 2; the hollow cylindrical cavity 3 passes through each baffle in turn, and the hollow cylindrical cavity 3 25 conical baffles 4 with upper openings distributed up and down are installed on the inner wall; a cylindrical adsorption filter 1 is installed on the upper end of the hollow cylindrical cavity 3; Mixed ga...

Embodiment 3

[0028] This embodiment is basically the same as Embodiment 1, except that there is one horizontal baffle and three conical baffles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com