Nox elimination injector firing control circuit

A technology of ignition control and injectors, which is applied in the direction of mufflers, machines/engines, chemical instruments and methods, etc., can solve problems such as sensitive lift tolerances, and achieve the effect of improving the closing response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

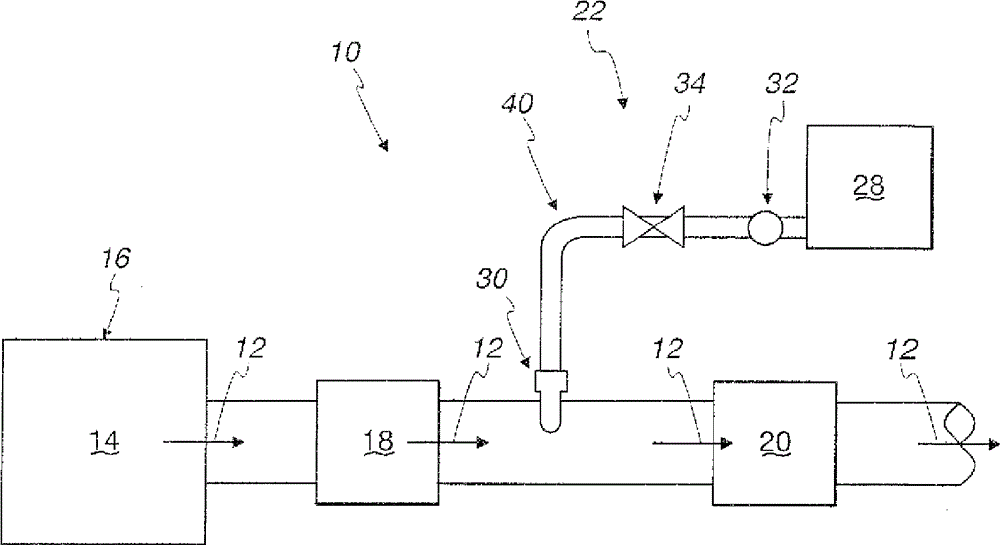

[0020] refer to figure 1 , a diesel exhaust aftertreatment system 10 is provided to treat emissions 12 from a diesel combustion process 14 (eg, a diesel compression engine 16 ). System 10 may include one or more exhaust treatment components 18 that clean and / or treat exhaust gas 12 , such as a diesel particulate filter (DPF), a combustor, a diesel oxidation catalyst (DOC), a lean NOx trap, and the like. There are many suitable types of configurations for such components, the choice of which is highly dependent on the parameters of each particular application.

[0021] System 10 also includes a selective catalytic reduction catalyst (SCR) 20 and a urea injection system 22 for injecting urea 24 into exhaust 12 upstream of SCR 20 . The urea injection system 22 will typically include a tank 28 or other type of container for the urea 24, one or more urea injectors 30, a pump 32 for pressurizing the urea 24 in the system 22, a pump 32 for controlling the A control valve 34 for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com