Axial vibration-resistant connector

A vibration-resistant, connector technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the problems of short-term disconnection, high cost, large volume, etc., and achieve convenient installation or disconnection, contact resistance Small, well adapted to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

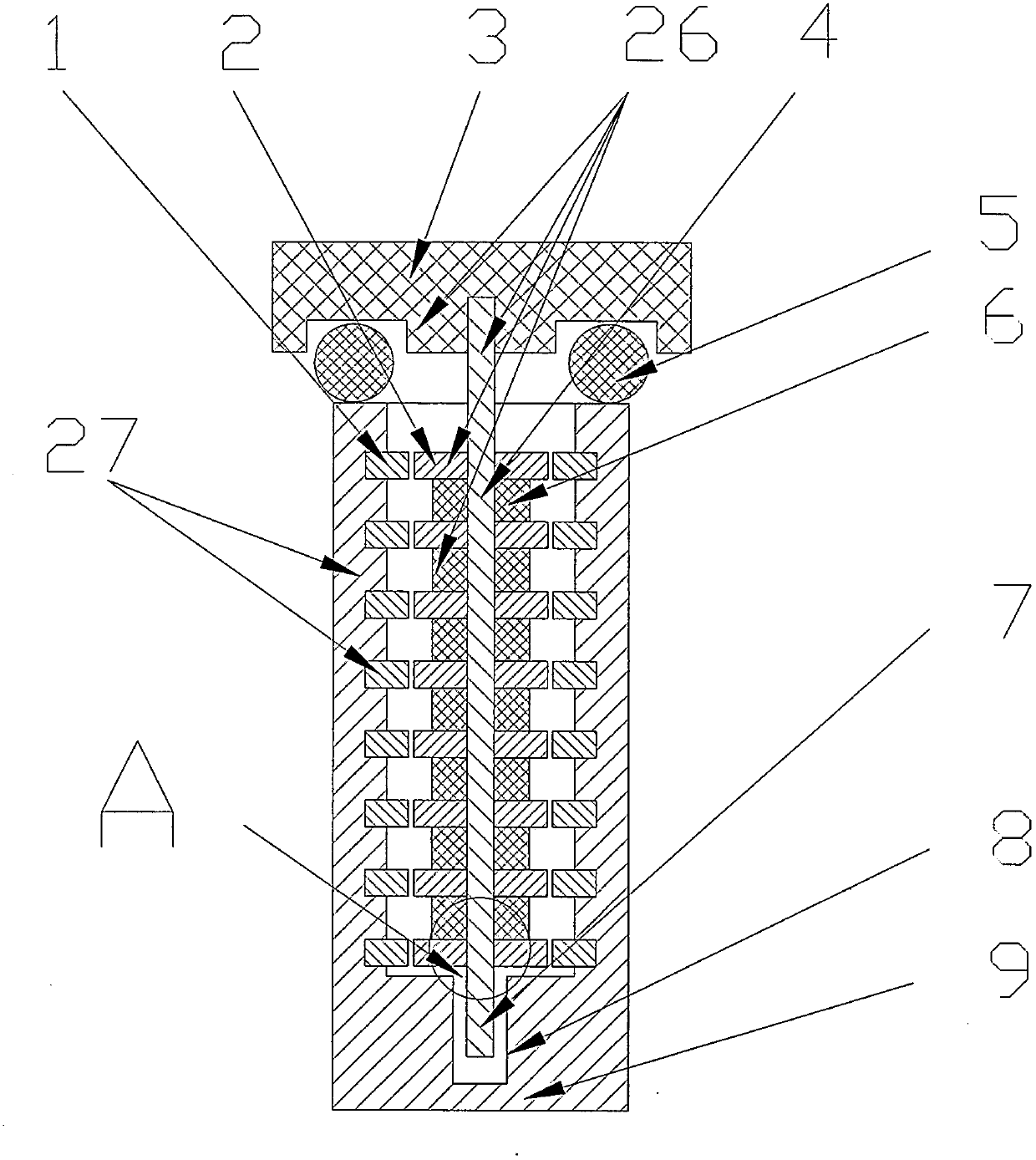

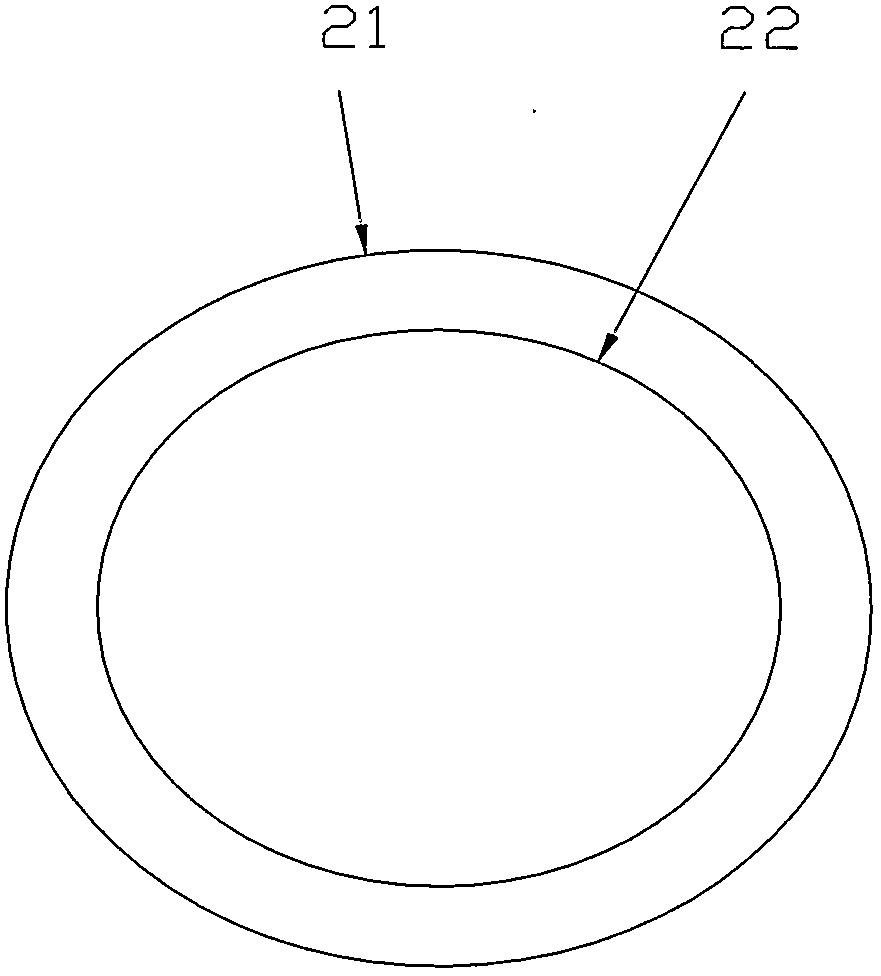

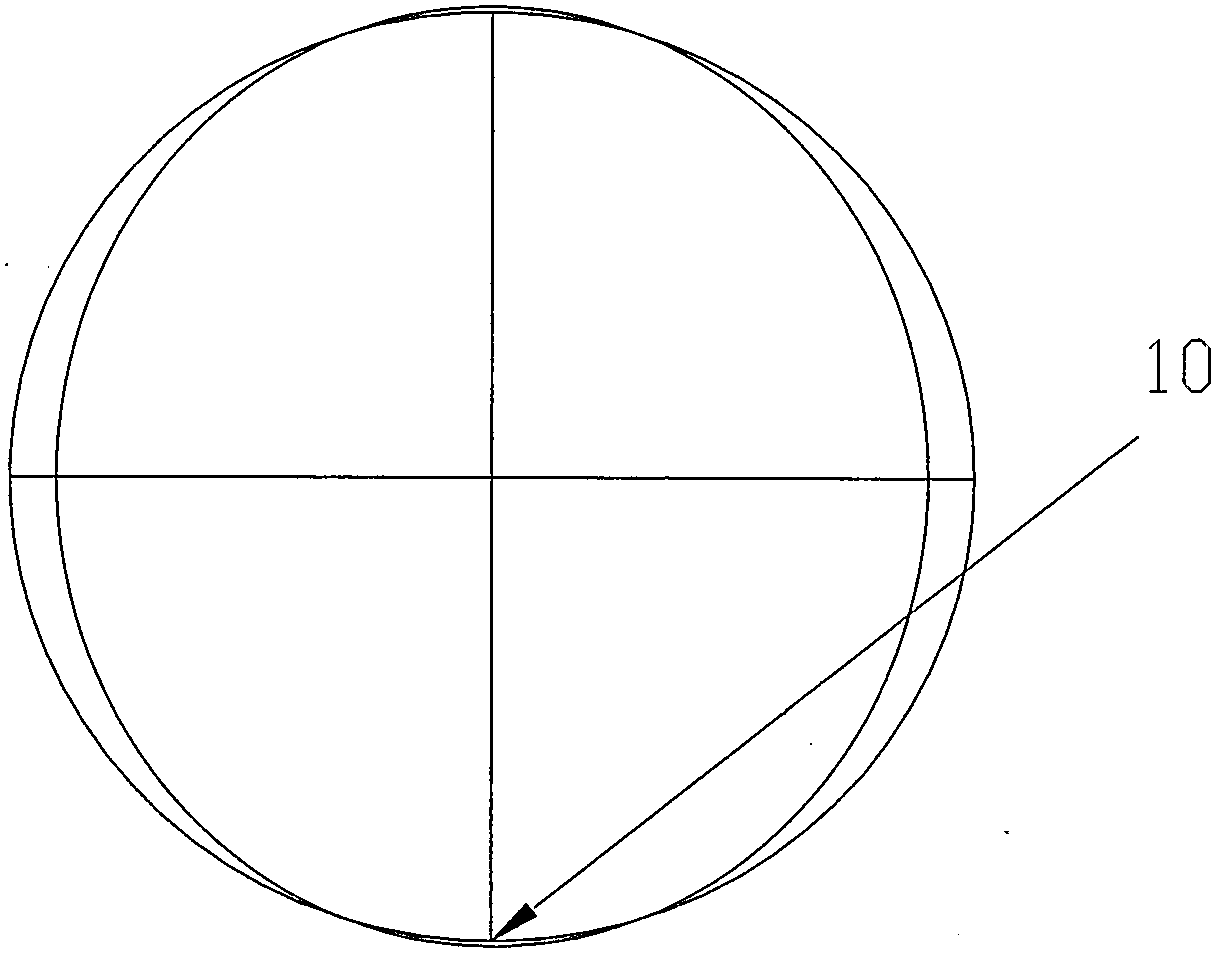

[0021] Refer to attached figure 1 , a shaft-type vibration-resistant connector is characterized in that: the plug shaft group (26) is composed of a plug (2), a plug shaft end cover (3), a plug shaft (4) and an insulating spacer (6), and the plug (2) 8 pieces are set, coaxially fixedly installed on the periphery of the plug shaft (4), and the insulating spacers (6) and the insulating spacers (6) are fixedly installed between the plugs (2) Coaxial fixedly installed on the periphery of the plug shaft (4), the long axis of the plug (2) is 24.4mm, the short axis is 24mm, the thickness is 3mm, the material is red copper, the plug shaft (4) is fixed and installed For the plug shaft end cover (3), the size of the plug shaft (4) is 12mm×12mm×30mm, the material is bakelite, and the socket hole group (27) is composed of a socket (1) and a socket shell (9). The socket (1) is provided with 8 pieces, and the socket (1) is coaxially fixedly mounted on the socket shell (9), and the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com