Antenna plate, touchpad, electronic device and manufacturing method of antenna plate for touchpad

A manufacturing method and technology of electronic equipment, which is applied in the field of touch panels, electronic equipment, and antenna boards for touch panels, can solve the problems of slow ultrasonic embedding speed, increased machine loss, and low production efficiency, so as to improve the embedding speed , Improve the yield and improve the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

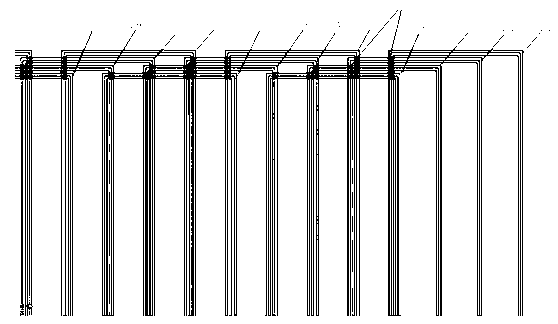

[0032] figure 1 It is a schematic diagram of the coil arrangement of the antenna board made by the ultrasonic buried wire method in the prior art.

[0033] The coils in the antenna board include coils arranged in the lateral direction (hereinafter referred to as the X direction) and coils arranged in the longitudinal direction (hereinafter referred to as the Y direction). figure 1 Shown are coils arranged in the X direction.

[0034] like figure 1 As shown, the coils 101 , 104 and 107 respectively have intersections with the coil 110 . In the prior art, the antenna board fabricated by the ultrasonic buried wire method often adopts the skipping method when encountering the intersections between the coils. This method reduces production efficiency and yield.

[0035] The study found, figure 1 The middle coils 101, 102, and 103 do not c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com