Vacuum packaging equipment for polymer lithium batteries after electrolyte injection

A vacuum packaging and lithium battery technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of low packaging efficiency and inconvenient packaging, improve production efficiency, ensure production quality, personnel Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

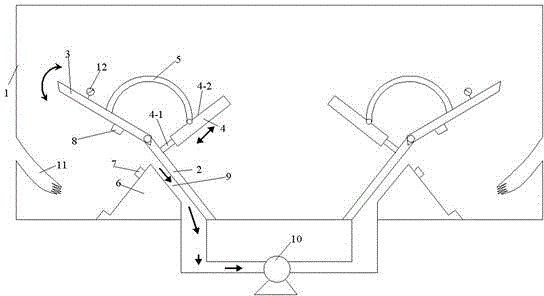

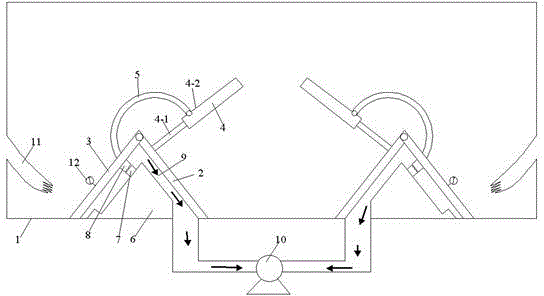

[0010] refer to figure 1 and figure 2 , the present invention relates to a vacuum packaging equipment for a polymer lithium battery after electrolyte injection, comprising a sealing cover 1, a packaging mechanism is arranged inside the sealing cover 1, and the packaging mechanism includes a fixed sealing plate 2 arranged obliquely and a hinged joint The movable sealing plate 3 on the upper part of the fixed sealing plate 2 and used to form the packaging space, the movable sealing plate reciprocates in an arc shape, the piston rod 4-1 of the driving cylinder 4 is fixedly connected to the fixed sealing plate 2, The cylinder body 4-2 of the driving cylinder 4 is connected to the movable sealing plate 3 through the connecting rod 5. In order to avoid the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com