Automatic controlling and operating system for whole mine

An automation control and mine technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of lack of portability and reference, low management decision-making level of coal enterprises, and low degree of informatization , to achieve the effect of avoiding sick operation, increasing the alarm range and increasing the service life of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

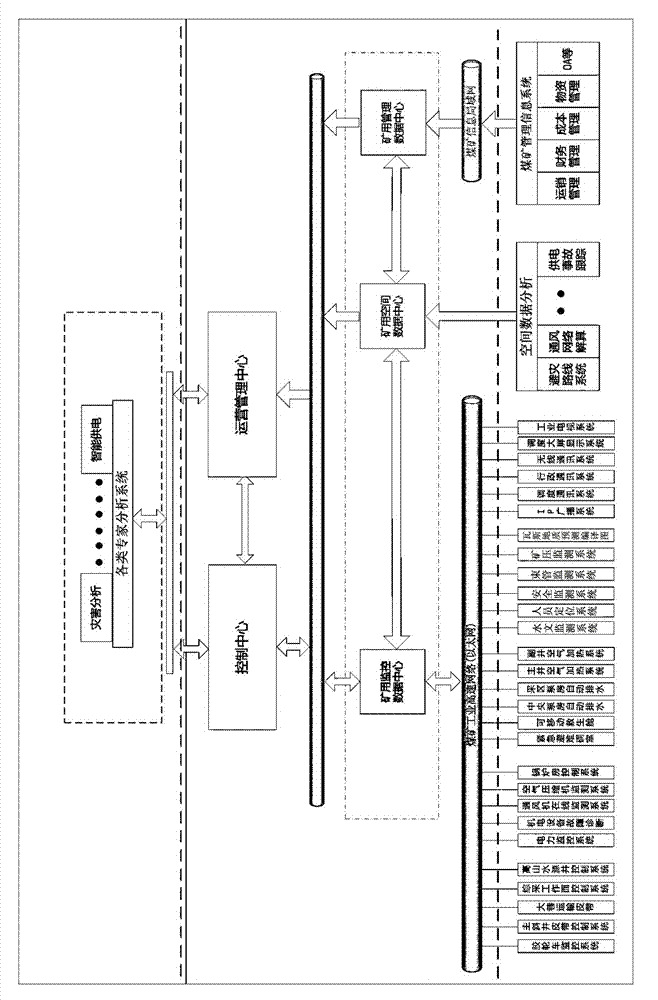

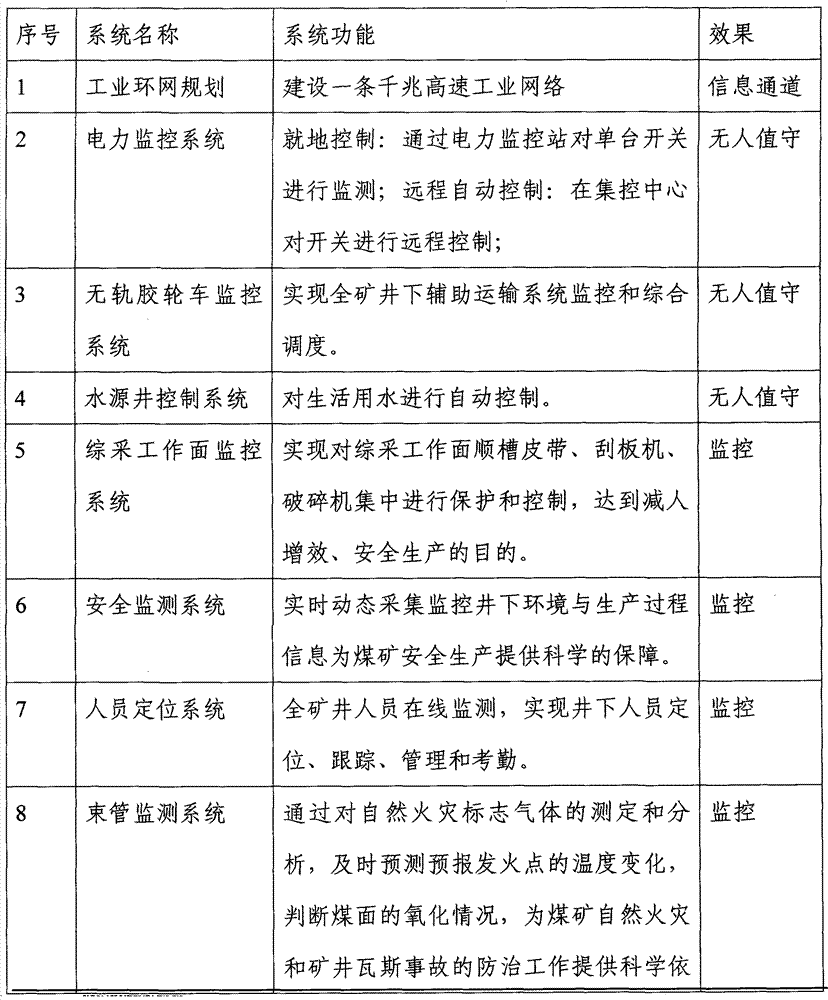

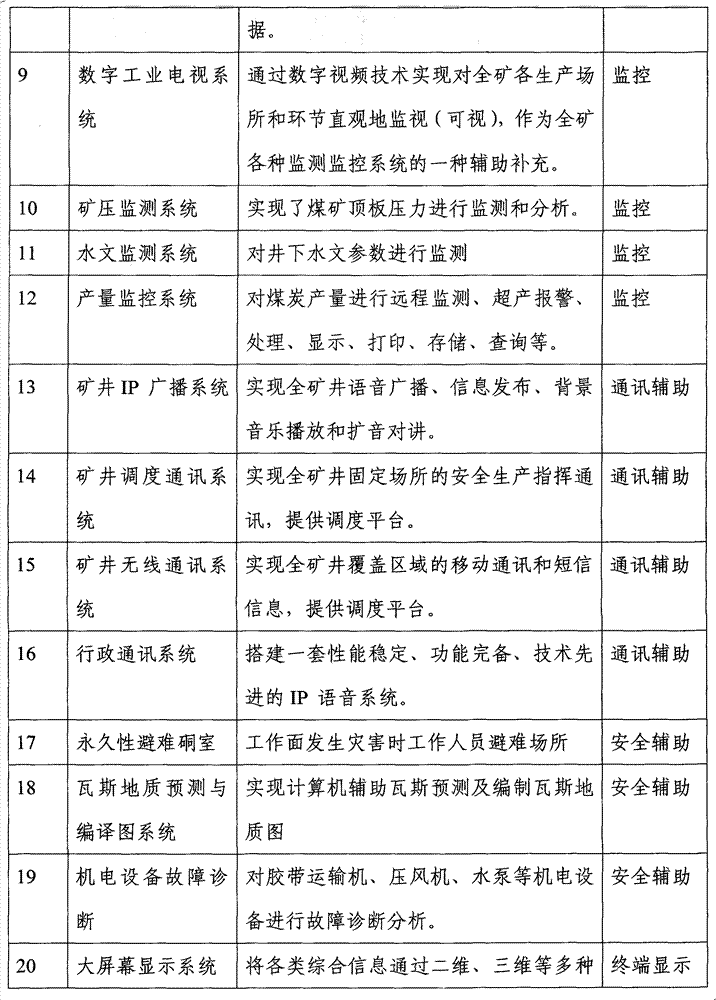

[0057] Such as figure 1 As shown, the present invention is a full mine automatic control and operation system, including expert analysis system, control center, operation management center, mine monitoring data center, mine space data center, mine management data center; expert analysis system, control center, operation management center, mining monitoring data center, mining space data center, and mining management data center are interconnected through the Gigabit industrial Ethernet ring network, and the expert analysis system reads the mining monitoring data center and mining space through the control center. The data in the database of the data center and mining management data center is analyzed by the expert analysis system or the instructions issued by the operator, and then the control center controls each subsystem; after each subsystem collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com