Facility for detecting methane concentration of coal mine

A technology for concentration detection and coal mine methane, which is applied to measurement devices, material analysis by optical means, instruments, etc., can solve the problems of inaccurate detection and low detection accuracy of mine methane measurement devices, and achieve good use value and measurement range. The effect of broad and large economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

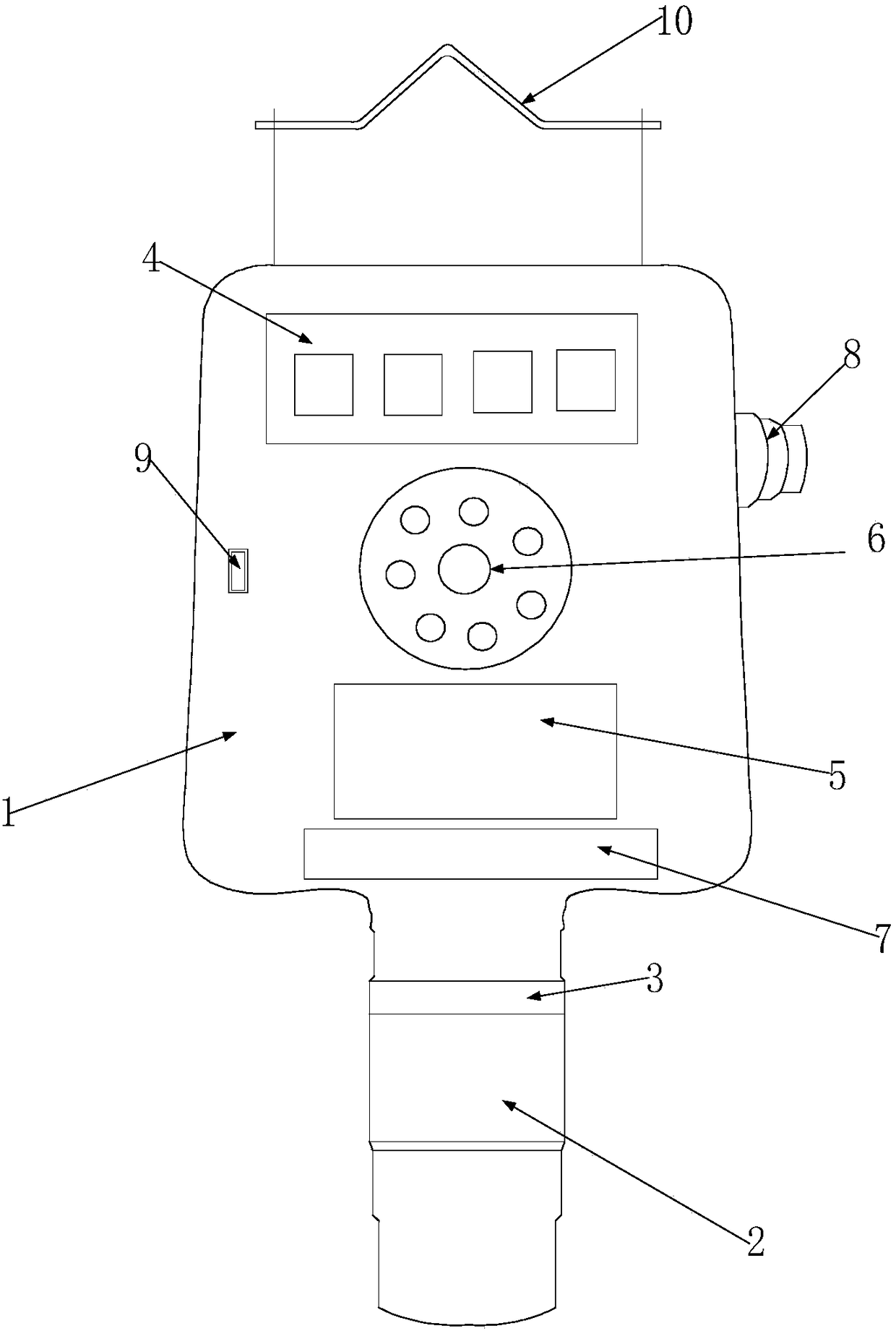

[0023] Such as figure 1 As shown, the equipment used for detecting methane concentration in coal mines includes a casing. The casing 1 is a cuboid structure. The casing 1 is stamped from 304 stainless steel. The casing 1 includes a front cover and a matching front cover. The back cover, the front cover and the back cover form a cavity structure, a rubber sealing ring is set between the front cover and the back cover, a handle 10 is set on the top of the casing 1, and an aviation joint 8 is set on the side of the casing 1 , the inside of the casing 1 is provided with a processor, the bottom of the casing 1 is provided with a laser gas detection assembly 2, a silicone sealing ring is provided between the laser detection element and the casing 1, and the laser gas detection assembly 2 includes sequentially connected Lasers, splitters, incident fiber collimators, incident light slots, sampling gas chambers, exit light slots, exit fiber collimators and array photodetectors, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com