Locking and automatic unlocking mechanism for two-dimensional tracking rotating-tables

An automatic unlocking and tracking turntable technology, applied in the direction of the locking device when the movable parts of the measuring device are not in use, can solve the problem of small locking torque and cannot be provided, and achieve high reliability, simple and reliable structure, pollution-free safety The effect of reliable recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

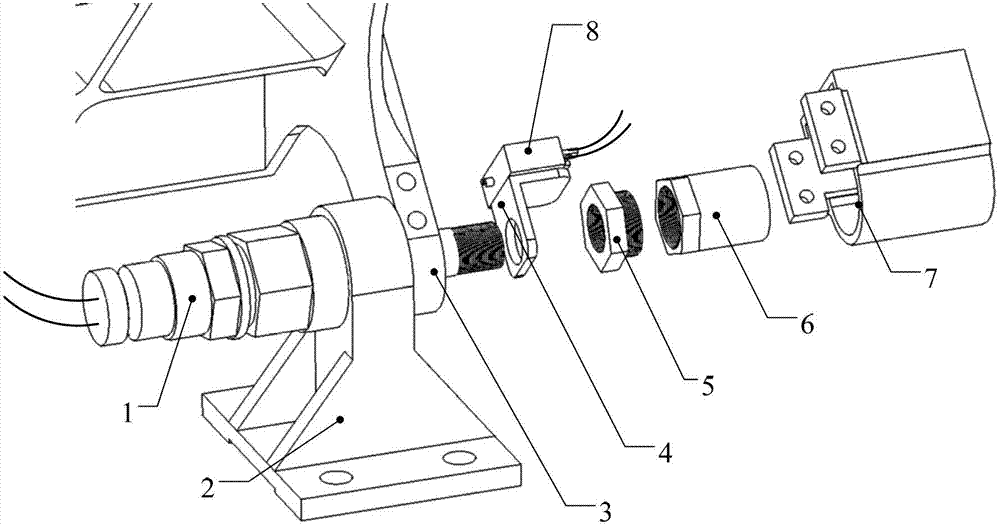

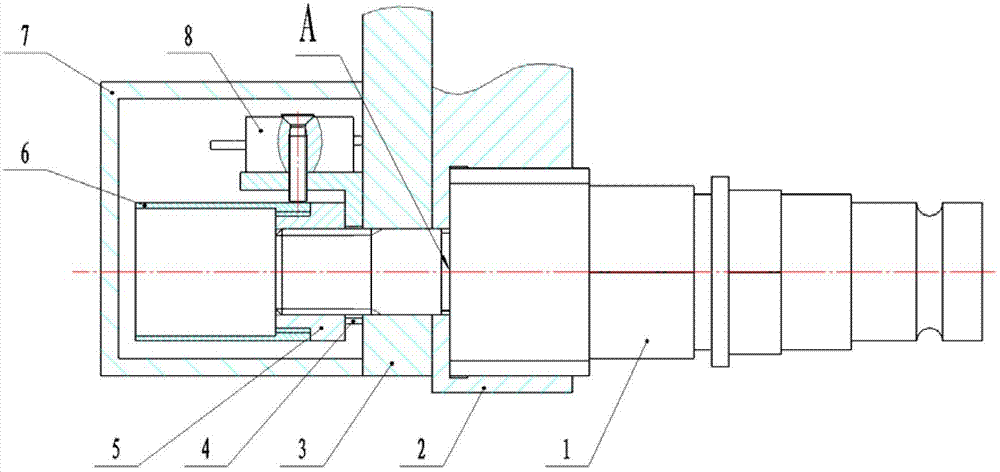

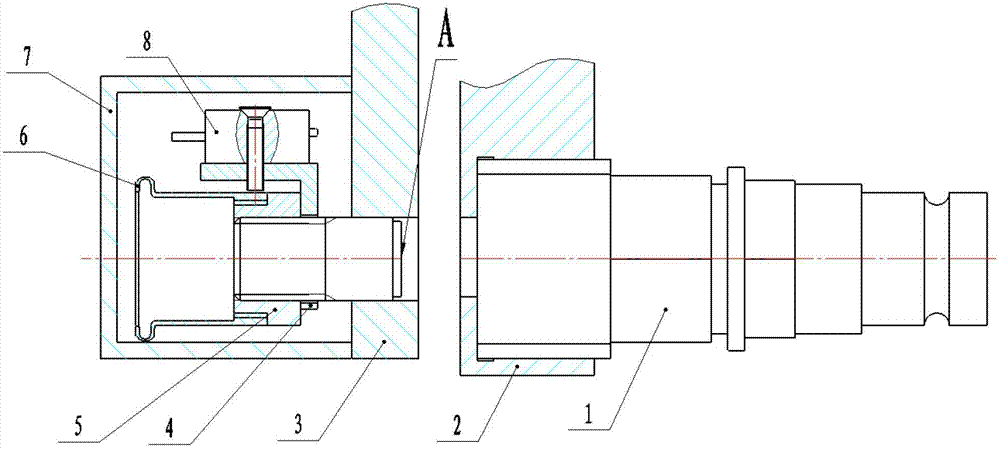

[0018] The invention is mainly used for the locking of the two-dimensional tracking turntable in the non-working state, can realize automatic unlocking according to the instruction, and is in the working state after unlocking. The mechanism and its use are illustrated below in conjunction with the accompanying drawings.

[0019] see figure 1 , the fixed support is fixedly connected with the installation datum, which is used to fix the explosion bolt and play the role of the mechanical limit of the turntable; the explosion bolt is the main force-bearing part of the mechanism, and bears the rotation moment and bending moment caused by vibration; the inside of the lock nut While the thread is firmly connected to the explosion bolt, the micro switch is pressed down through the micro switch mounting seat to generate a locking signal (indicating the current locking state), and its external thread is firmly connected to the buffer ring.

[0020] The rotating part and the fixed suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com