Quick pipeline quick leakage stopper and processing and forming method thereof

A technology of plugging device and pipeline, applied in the direction of pipe elements, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of difficulty in centering the upper and lower sealing strips, weakening the side sealing force, and increasing the cost of sealing strips. Easy positioning, reduced rubber material consumption, ease of use and effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

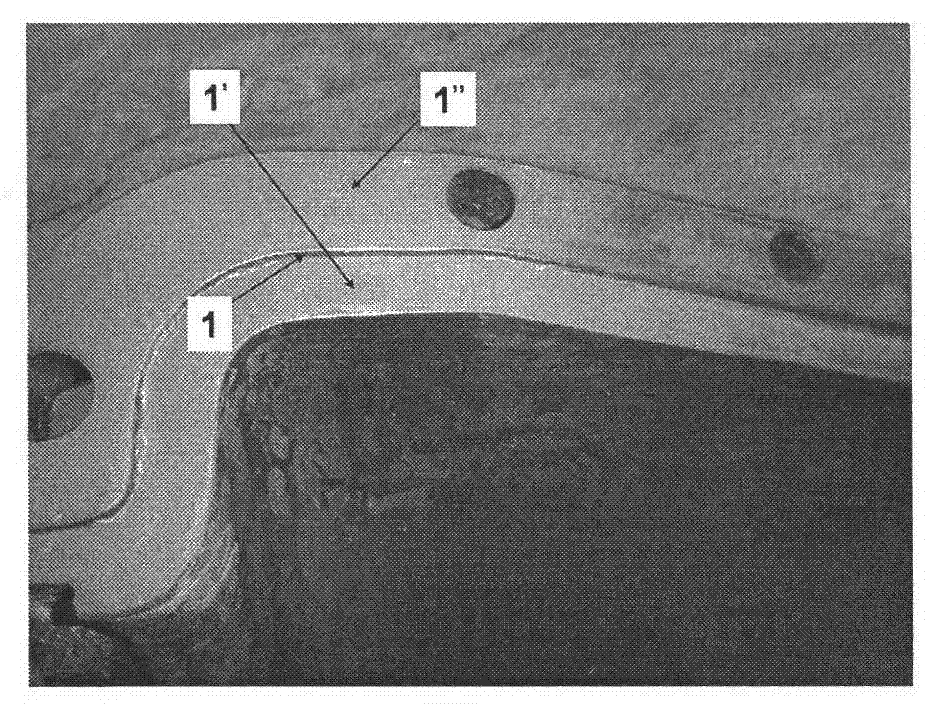

[0045] Cement pipes are still one of the main pipes for water supply in many cities in my country. The connection between cement pipes and pipes mainly adopts the socket method. The outer surface of the tail end of the previous section of pipe is covered with a sealing ring and then inserted into the front end of the subsequent section of pipe. The sealing ring at the socket is the most likely to be damaged and leak. One of them, the leak stopper used for rapid plugging at this position is called the cement pipe socket type Huff joint.

[0046] According to the national standard of DN300 cement pipe socket joint, determine its basic external dimensions, and then according to the design experience, after enlarging a certain proportion, determine the internal dimensions of the cement pipe socket DN300 leak stopper shell.

[0047] The thickness of the side flange is determined according to the flange design specification of DN300, and the material performance data is obtained by ...

Embodiment 2

[0050] Also for the DN300 cement pipe socket plugging device, its shell is prepared by molding.

[0051] Based on the material performance data obtained by dividing the tensile properties of the molded glass fiber reinforced resin material by the safety factor, the shell size of the DN300 cement pipe socket plugging device is designed, and then the metal convex and concave molds are designed and processed. After the two molds are closed The mold cavity space is the shell structure size of the leak stopper, and electric heating tubes are respectively embedded in the metal convex and concave molds for heating the mold. The die is fixed on the base of a 1000-ton press, and the punch is fixed on the movable platen of the press, and the punch and the die are matched by moving down the platen of the press. First, after closing the convex and concave molds, heat up to make the temperature in the mold cavity reach 150°C. Then, move the convex mold up and put a sufficient amount of phe...

Embodiment 3

[0053] Also for the DN300 cement pipe socket plugging device, its shell is prepared by spray molding.

[0054] Based on the modulus and strength of the chopped fiber reinforced composite material, the shell size of the DN300 cement pipe socket leak stopper is designed, and the metal convex and concave molds are further designed and processed. The mold cavity space after the two molds are closed is the leak stopper The size of the shell structure, the feed port and the air outlet connected with the cavity are set at the appropriate part of the mold, and the outer cover of the metal plug is placed in the die, and the feed port of the cavity is connected with the screw extruder. The discharge port is connected, and a cooling water flow channel is arranged in the mold. Mix chopped glass fiber and nylon pellets at a weight ratio of not less than 20% (that is, the weight ratio of chopped fiber in the mixture is not lower than 20%), and then put them into the feeding bin of the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com