Production method of butyl alcohol by fermentation of biomass coupled with pervaporation separation

A biomass fermentation and pervaporation technology, which is applied in the field of biomass fermentation coupled with pervaporation separation and production of butanol, can solve problems such as high energy consumption, improve separation efficiency, improve fermentation yield and substrate utilization, and reduce inhibition effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. The fermentation substrate undergoes continuous fed-batch biomass fermentation to obtain butanol fermentation broth

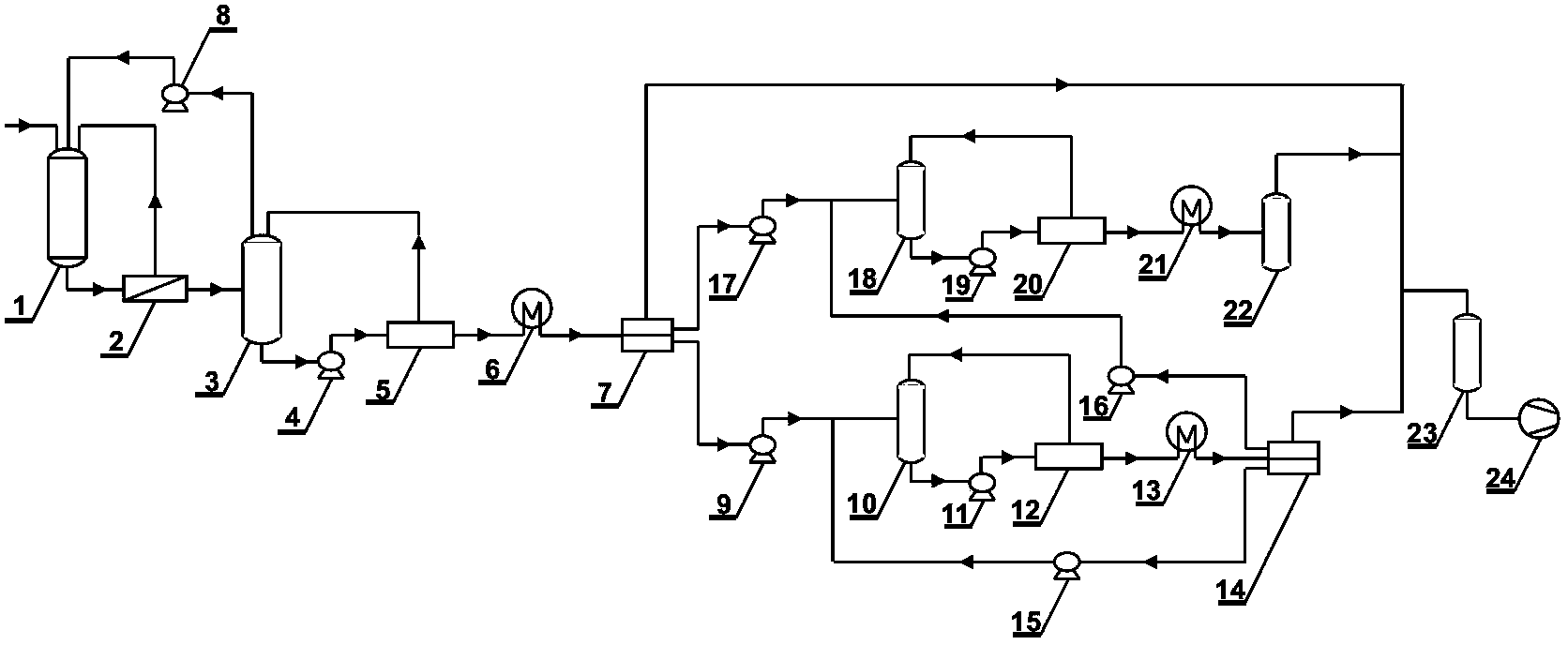

[0049] In this process, continuous fed-batch anaerobic fermentation is carried out with glucose as the fermentation substrate to obtain butanol fermentation broth. The process flow diagram is shown in figure 1 .

[0050] (1) Prepare culture medium

[0051] Prepare a synthetic medium with glucose as the fermentation substrate. The medium consists of glucose 60g / L, ammonium acetate 2.2g / L, potassium dihydrogen phosphate 1g / L, dipotassium hydrogen phosphate 1g / L, magnesium sulfate 0.3g / L and Other trace elements and growth factors. The prepared synthetic medium was transferred into the fermenter 1 for high-temperature sterilization, and after the temperature in the fermenter 1 dropped to 40° C., sterile nitrogen was introduced to create an oxygen-free environment.

[0052] (2) Vaccination

[0053] Inject the activated strain Clostridium acetobutylicu...

Embodiment 2

[0068] 1. The fermentation substrate is subjected to batch biomass fermentation to obtain butanol fermentation liquid

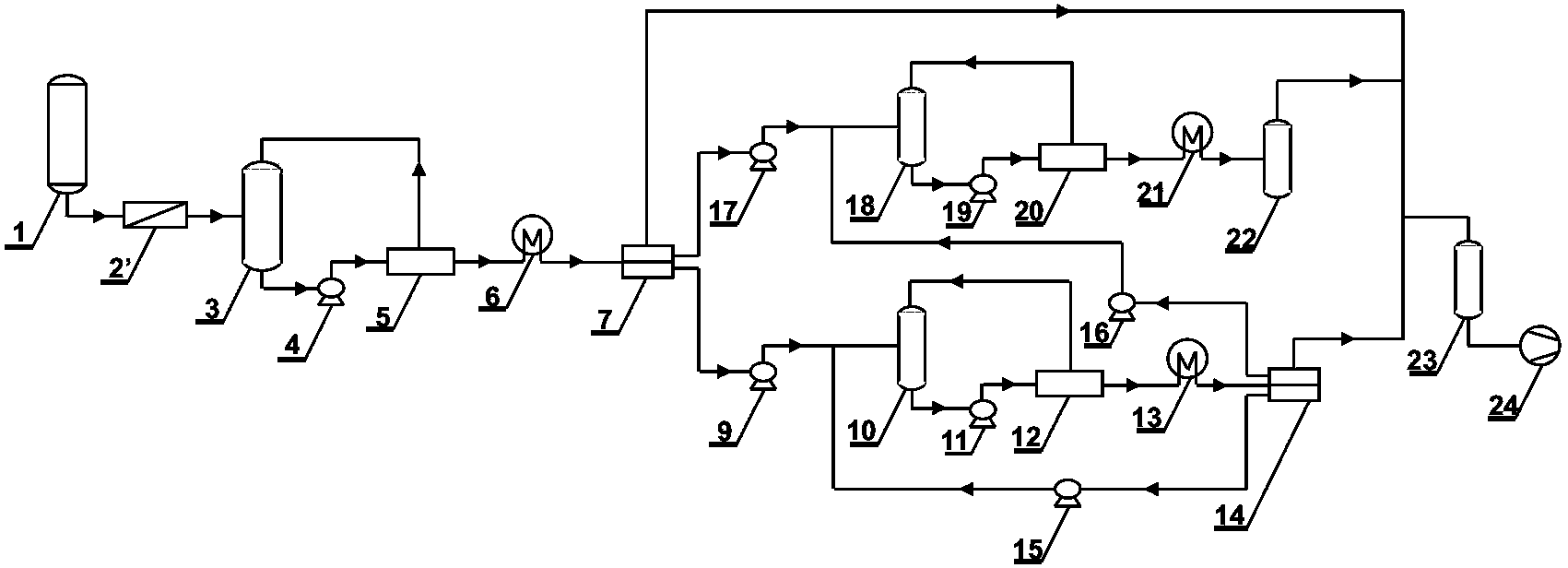

[0069] In this process, the butanol fermentation broth is obtained by intermittent anaerobic fermentation using sugars in the sweet sorghum slag hydrolyzate as a carbon source. The schematic diagram of the process is shown in figure 2 .

[0070] (1) Prepare culture medium

[0071] The medium is prepared with sweet sorghum slag hydrolyzate as the substrate, and the medium is composed of total sugar 50g / L, potassium dihydrogen phosphate 0.9g / L, dipotassium hydrogen phosphate 0.9g / L, magnesium sulfate 0.25g / L and other trace amounts elements and growth factors. The prepared medium was transferred into the fermenter 1 for high-temperature sterilization, and after the temperature in the fermenter 1 dropped to 40° C., sterile nitrogen was introduced to create an oxygen-free environment.

[0072] (2) Vaccination

[0073] Inject the activated strain Clostridium ...

Embodiment 3

[0087] 1. The fermentation substrate is fed-batch biological fermentation to obtain butanol fermentation liquid

[0088] In this process, the butanol fermentation liquid is obtained by fed-batch anaerobic fermentation with the carbohydrates in the sap of sweet sorghum stalk as the carbon source. The process flow diagram is shown in figure 2 .

[0089] (1) Prepare culture medium

[0090] Prepare the medium with sweet sorghum stalk juice as the substrate, the medium composition is 65g / L of total sugar, 0.8g / L of potassium dihydrogen phosphate, 0.8g / L of dipotassium hydrogen phosphate, 0.25g / L of magnesium sulfate and other trace amounts elements and growth factors. The prepared medium was transferred into the fermenter 1 for high-temperature sterilization, and after the temperature in the fermenter 1 dropped to 40° C., sterile nitrogen was introduced to create an oxygen-free environment.

[0091] (2) Vaccination

[0092] Inject the activated strain Clostridium acetobutylicu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com