Preparation method of acidic crosslinking agent applied to carboxymethyl guar gum

A technology of carboxymethyl guar gum and cross-linking agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that cannot fully meet the requirements of the site, and achieve good sand-carrying performance and high temperature resistance , the effect of simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

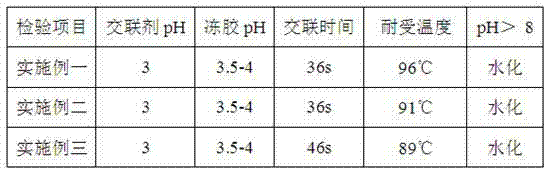

Embodiment 1

[0028] Mix 3 parts by weight of citric acid, 57 parts by weight of water, and 20 parts by weight of sucrose evenly. When the temperature of the system rises to 50°C, add 20 parts by weight of zirconium oxychloride, maintain the temperature at 55°C, and react for 3 hours. The obtained transparent and uniform liquid is the acidic organic zirconium crosslinking agent.

Embodiment 2

[0030] Mix 3 parts by weight of citric acid, 77 parts by weight of water, and 1.5 parts by weight of glucose evenly. When the temperature of the system rises to 50°C, add 5 parts by weight of zirconium oxychloride, maintain the temperature at 50°C, and react After 3.5 hours, the obtained transparent and uniform liquid is the acidic organic zirconium crosslinking agent.

Embodiment 3

[0032] Mix 3 parts by weight of citric acid, 77 parts by weight of water, and 10 parts by weight of sorbitol evenly. When the temperature of the system rises to 50°C, add 10 parts by weight of zirconium oxychloride, keep the temperature at 50°C, and react for 4 hours . The obtained transparent and uniform liquid is the acidic organic zirconium crosslinking agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com