Alternative adhesive powder for industrial flour and preparation method

A technology of gluing powder and flour, applied in the direction of starch-derived adhesives, adhesive types, adhesive additives, etc., can solve the problems of no increase in water resistance, toughness, inability to capture formaldehyde, single effect, etc., and achieve improved water resistance , Improve water resistance, reduce the effect of formaldehyde content

Inactive Publication Date: 2013-05-29

LANGFANG TAIHETONG CHEM

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In addition, traditional flour only has the functions of absorbing water, thickening, and instantly increasing viscosity in the glue mixing process. It has a single effect and cannot capture formaldehyde in wood-based panels, let alone increase water resistance and toughness.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment 1

[0041] Formula ratio: A material 30, B material 38, C material 14, D material 12, E material 1, F material 3, G material 0.8, H material 1.2;

specific Embodiment 2

[0042] Formula ratio: A material 20, B material 50, C material 10, D material 10, E material 2, F material 4, G material 1, H material 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

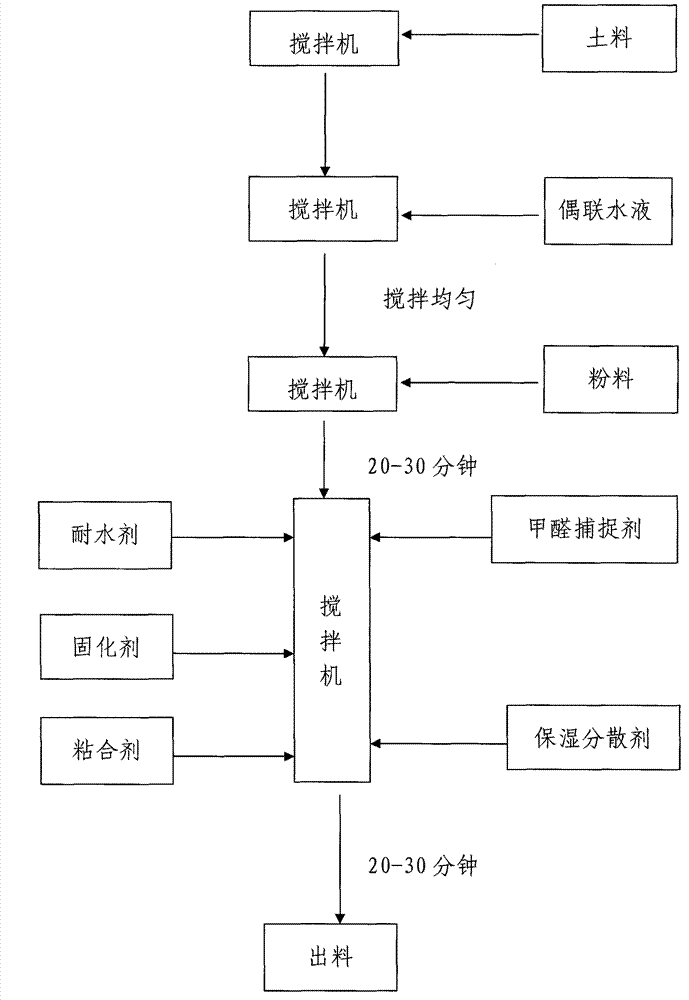

The invention discloses an adhesive powder capable of replacing the traditional industrial wheat flour, which is featured with grain saving, low cost and highly water resistance and is used for effectively catching formaldehyde and reducing formaldehyde content, and a preparation method. According to the invention, a formula of the adhesive powder comprises the following materials in percentage by weight: a material A: a soil material using 20-50% of sodium based soil; a material B: a powder material using 30-60% of cypress powder; a material C: an adhesive using 10-20% of solid oxidized starch adhesive; a material D: a water resistant agent using 10-15% of shale; a material E: a moisturizing dispersant using 0.8-2% of sodium lauryl sulfate; a material F: a formaldehyde catching agent using 2-4% of sodium percarbonate; a material G: a curing agent using 0.3-1.2% of aluminum sulfate and a material H: a coupling agent using 1-3% of K-602.

Description

technical field [0001] The invention relates to the field of rubber fillers for plate processing, in particular to a glue powder for replacing industrial flour and a preparation process thereof. Background technique [0002] Humans have a long history of using wood adhesives. In the 17th and 18th centuries, European and American countries had established adhesive factories. At the beginning of the 19th century, commercial casein was available in Europe, and the commercial production of adhesives gradually developed. At the end of the 19th century and the beginning of the 20th century, synthetic resins entered the field of adhesives. In the 1930s, the wood industry began to use phenolic and urea-formaldehyde resin glues. In order to prolong the shelf life, this kind of glue is generally made thinner when it leaves the factory. Therefore, wood-based panel companies add industrial wheat flour to the glue before production. , to absorb water, thicken and increase instant visco...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09J197/02C09J103/10C09J11/04C09J11/06

Inventor 吕文彰

Owner LANGFANG TAIHETONG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com