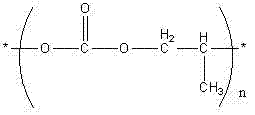

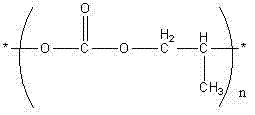

Fully-degradable poly propylene carbonate/wood meal composite foaming material and preparation method thereof

A polymethylethylene carbonate and composite foaming technology, which is applied in the field of fully degradable polymethylethylene carbonate/wood powder composite foaming materials and its preparation, can solve the mechanical properties of toughness, impact strength and bending strength Reduce problems such as limitations in the application field of wood-plastic composite materials, and achieve the effects of high toughness, high impact strength, and good woody feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0053] The fully degraded polymethylethylene carbonate / wood powder composite foam material of embodiment 1~4 is prepared by the formula listed in table 1. Its preparation process is:

[0054] (1) Add polymethylethylene carbonate and wood flour to a high-speed mixer with a rotation speed of 800 rpm and a temperature of 115°C for hot mixing. After mixing for 8 minutes, add plasticizers, coupling agents, and lubricants agent and heat stabilizer, mixed for another 6 minutes, transferred the mixed material to a cold mixer and cold mixed to 40°C, added a foaming agent, a foam stabilizer and a nucleating agent, and mixed evenly to obtain a mixed material;

[0055] (2) Put the mixed material into an embedded planetary screw extruder at 150°C and extrude, then foam through a foaming mold, cool and shape.

[0056] Table 1

[0057] Example 1 2 3 4 PPC (parts by weight) 80 60 40 30 Wood flour (parts by weight) 20 40 60 70 DBP (parts by weight) 10 10...

Embodiment 5~8

[0061] The formula listed in Table 2 and the process of Table 3 were used to prepare the fully degradable polymethylethylene carbonate / wood flour composite foaming material of Examples 5-8.

[0062] Table 2

[0063] PPC (parts by weight) 60 Wood flour (parts by weight) 40 DBP (parts by weight) 10 Titanate (parts by weight) 2 Zinc stearate (parts by weight) 3 AC (parts by weight) 10 Methyl silicone oil (parts by weight) 5 Calcium carbonate (parts by weight) 1 Talc powder (parts by weight) 2

[0064] table 3

[0065] Example 5 6 7 8 High speed mixer speed 500 700 800 1000 High speed mixer temperature 110 115 115 110 extruder temperature 110 120 130 150 Cell morphology □ □ ○ ○ Density / (g·cm -3 ) 1.10 0.96 0.85 0.82 Elongation at break / % 2.8 2.9 3.3 3.4 Bending strength / MPa 29.5 32.0 36.5 36.9 Impact strength / (kJ m -2 ) 4.0 4.3 4.8 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com