Movable sling for mounting expansion joint of comb plate

A technology for expansion joints and installation, which is applied in the direction of hoisting devices, portable lifting devices, etc., can solve problems such as difficult movement of cranes, manpower restrictions, and uneconomical problems, so as to avoid personal safety problems, enhance strength and rigidity, and save economic costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

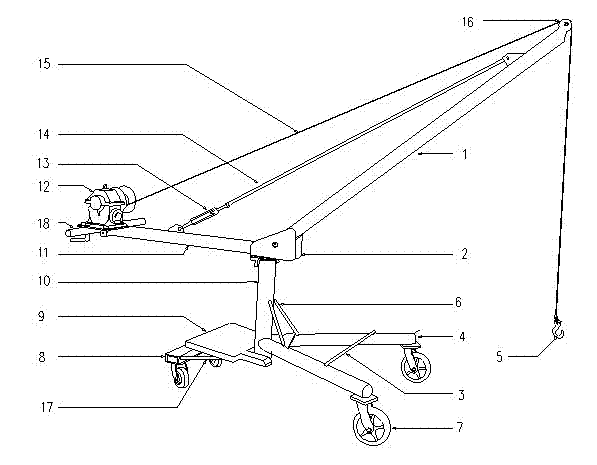

[0030] Embodiment: make according to the data in the following table,

[0031] mark structure name Specification Length (mm) material 1 jib O102X5 2300 Q2358 steel 2 connector L50X10 250 Q2358 steel 3 first reinforcement tube O20X3 400 Q2358 steel 4 support arm O102X5 800 Q2358 steel 5 hook 200Kg DG20 steel 6 second reinforcement tube O20X3 250 Q2358 steel 7 Universal wheel O152 cast iron 8 Bottom wheel stay L100X10 500 Q2358 steel 9 Weighted brace 20 400 Q2358 steel 10 support column O152X10 500 Q2358 steel 11 rear arm O102X5 1000 Q2358 steel 12 hoist JM0.3T 13 fastener 100KN Q2358 steel 14 Fasten the cable O20 2100 Hemp cored steel 15 active cable O11 5000 Hemp cored steel 16 fixed pulley 50KN cast iron 17 The third reinforcement tube O20X3 250 Q2358 steel 18 Four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com