Rotation vehicle of crane

A technology for cranes and trolleys, applied in the direction of heavy-duty pulleys, load hanging components, transportation and packaging, etc., can solve the problems of decreased product competitiveness, increased use costs of cranes, hidden safety hazards, etc., and achieves improved safety factor, convenient and quick assembly, The effect of strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

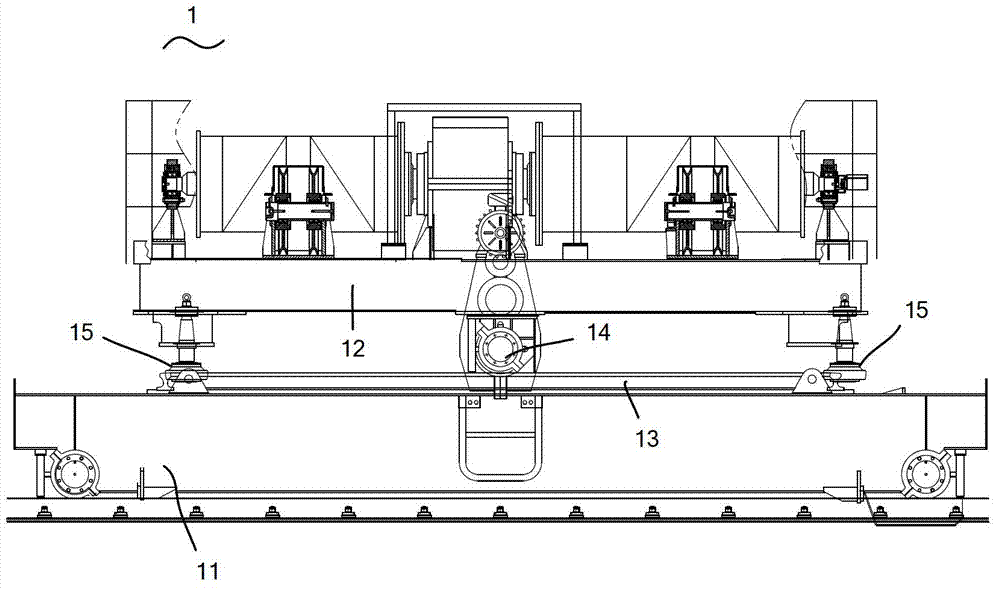

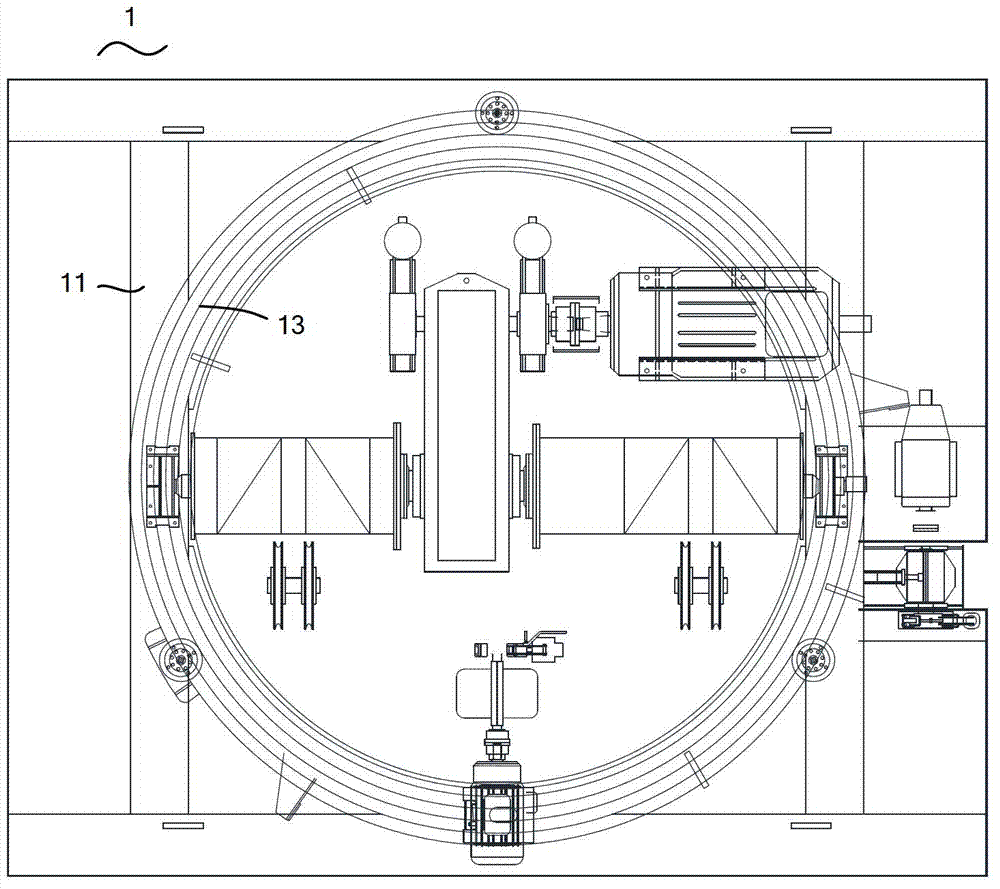

[0021] Crane rotary trolley 2 structure of the present invention is as Figure 4-Figure 6 Shown, comprise top dolly 22, bottom dolly 21 and slewing mechanism. The upper dolly 22 is installed on the top of the lower dolly 21 by a slewing mechanism, and can rotate on the top of the lower dolly 21 by a slewing mechanism.

[0022] Such as Figure 4 to Figure 7 As shown, the slewing mechanism includes a driving device 23 , a pinion 24 , a matching supporting outer ring gear 25 , a supporting inner ring 26 and a plurality of rollers 27 . The driving device 23 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com