Special tungsten steel-tungsten steel welded type cutter for PCBs (printed circuit boards)

A technology of PCB board and tungsten steel, which is applied in the direction of milling cutters, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing pollution, wasting resources, increasing costs, etc., and achieve the effect of reducing production costs and saving rare metal tungsten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

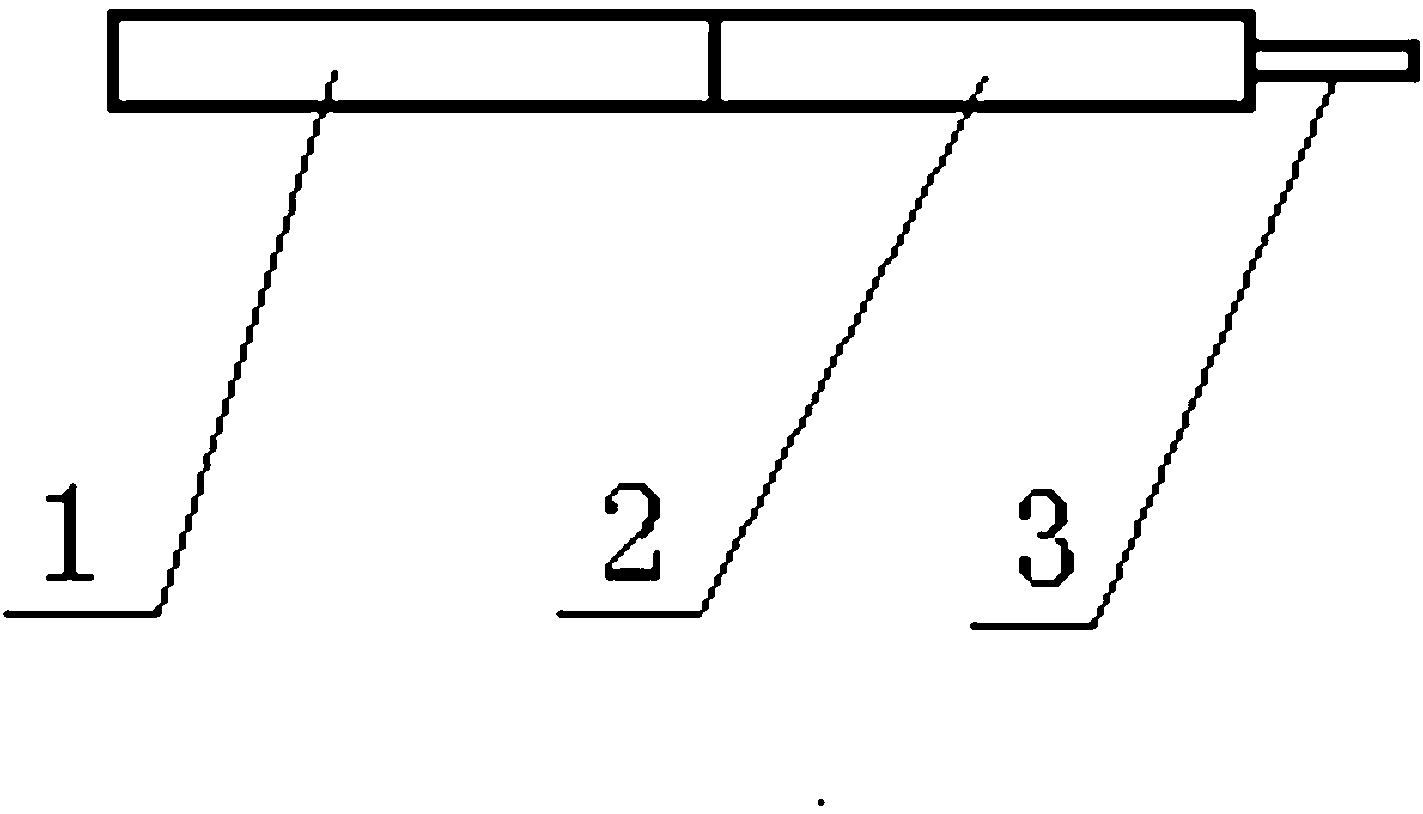

[0009] A special cutting tool for tungsten steel welding tungsten steel PCB boards, comprising a tungsten steel handle 1, a tungsten steel head 2, and a cutter head 3, the tungsten steel handle 1 and the tungsten steel head 2 are connected by silver soldering pieces. The silver welding temperature for connecting the tungsten steel shank 1 and the tungsten steel head 2 is 400°C-420°C.

[0010] The overall length of the cutter of the device of the present invention remains unchanged: 38.30mm, with 14.0mm, 14.40mm, 13.50mm, etc. of the head material of the tungsten steel head 2, and the corresponding tungsten steel handle 1 handle material has 24.40mm, 24.0mm, 24.90mm etc. The head and handle are welded together by silver welding. The temperature used during welding is between 400°C and 420°C. This temperature does not change the performance of the tungsten steel, and at the same time achieves the purpose of reuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com