Cyanide based electrolytic gold plating solution and plating method using same

A technology of cyanide alloy and conductive salt, which is applied in the field of cyanide-based electrolytic gold plating baths, can solve problems such as inability to perform cathodic current plating, and achieve the effects of excellent liquid stability, increased productivity, and shortened plating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

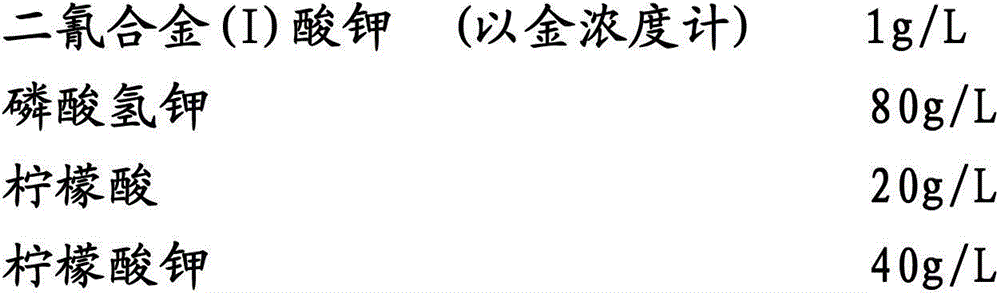

[0091] Under the plating conditions shown in Table 2, gold plating films were respectively formed on the samples and the BGA panel using a plating bath having the following composition.

[0092]

[0093] The film thickness of the obtained gold-plated film was 0.70-0.75 micrometers, and it was a uniform semi-glossy shape. As shown in Table 2, the cathode current density is 0.05~0.4A / dm 2Within the range of the cathode current efficiency, film thickness deviation, lead pull test and solder ball shear test results are good.

[0094] (Table 2)

[0095]

Embodiment 2

[0103] Under the plating conditions shown in Table 4, gold plating films were respectively formed on the samples and the BGA panel using a plating bath having the following composition.

[0104]

[0105] The film thickness of the obtained gold-plated film was 0.70-0.75 micrometers, and it was a uniform semi-glossy shape. As shown in Table 4, the cathode current density is 0.05~0.4A / dm 2 Within the range of the cathode current efficiency, film thickness deviation, lead pull test and solder ball shear test results are good.

[0106] (Table 4)

[0107]

Embodiment 3

[0109] Under the plating conditions shown in Table 5, gold-plated films were formed on the samples and the BGA panel, respectively, using a plating bath having the following composition.

[0110]

[0111]

[0112] The film thickness of the obtained gold-plated film was 0.70-0.75 micrometers, and it was a uniform semi-glossy shape. As shown in Table 5, the cathode current density is 0.05~0.4A / dm 2 Within the range of the cathode current efficiency, film thickness deviation, lead pull test and solder ball shear test results are good.

[0113] (table 5)

[0114]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cathode current density | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Cathode current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com