Low-frequency dipole transmitting transducer

A technology for transmitting transducers and dipoles, which is used in surveying, wellbore/well components, earth-moving drilling, etc. To achieve high-power transmission and other issues, to achieve the effect of broadening the bandwidth and facilitating high-power design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

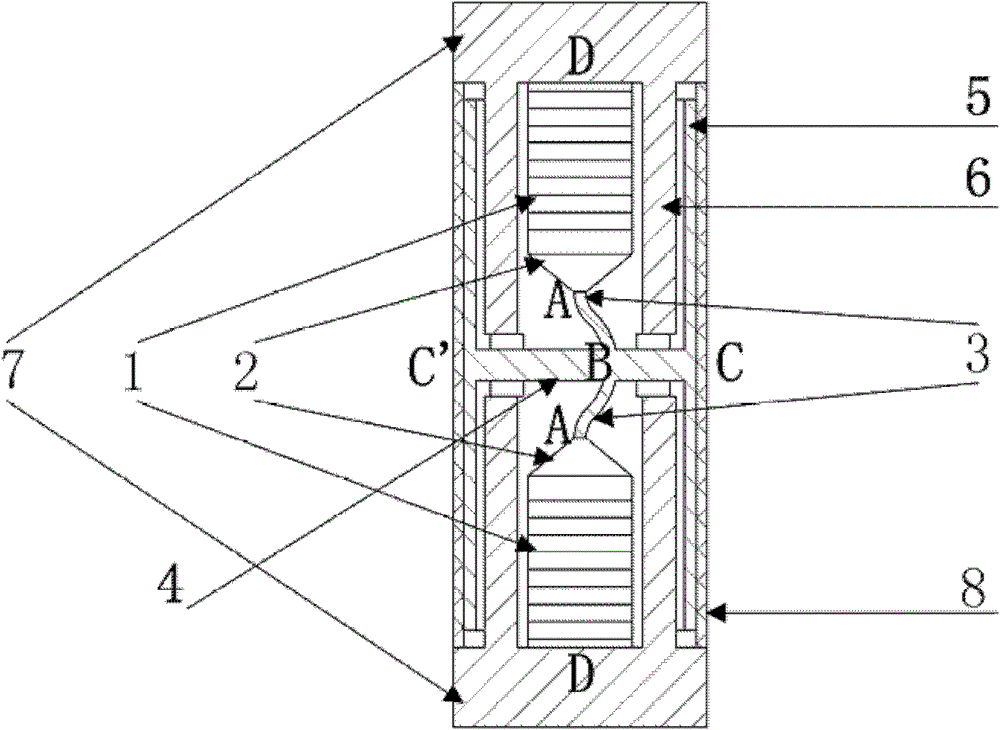

[0026] Next, the present invention will be further described according to the accompanying drawings

[0027] The transducer consists of two sets of ceramic stacks 1, transition rods 2, curved beams 3, transition beams 4, swing columns 5, rigid beams 6, end cover plates 7 and watertight layers 8. The overall length of the transducer in the embodiment is 193mm. Among them, the ceramic stack 1 is made of PZT-4 piezoelectric ceramics; the transition rod 2, the bending beam 3, the transition beam 4, and the swing column 5 are all made of TC4 titanium alloy; the rigid beam 6 and the end cover plate 7 are made of 45# steel, watertight Layer 8 adopts JA-2S polyurethane rubber.

[0028] The ceramic stack 1 is divided into two groups, and each group of ceramic stacks is mechanically bonded in series by eight φ30mm×5mm polarized ceramic sheets and one φ30mm×2mm non-polarized ceramic sheet. The direction of the electrodes of the sheet ceramics is opposite, and the unpolarized ceramic sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com