Sleeve gas collection device and method

A technology for collecting device and casing gas, which is used in earth-moving drilling, fluid production, wellbore/well components, etc., can solve problems such as impracticality, and achieve the effects of simple construction, reduced environmental pollution, and reduced waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

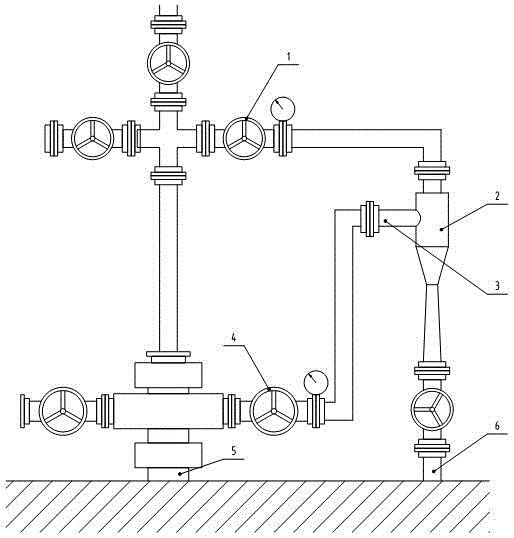

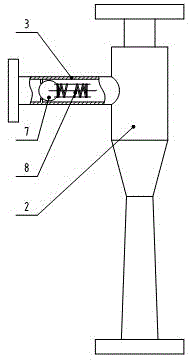

[0011] see figure 1 and figure 2 , figure 1 It is a schematic diagram of the installation of an embodiment of the casing gas collection device on the electric submersible pump well, figure 2 It is a structural diagram of an embodiment of the casing gas collection device. Install a jet pump 2 between the oil outlet valve 1 of the oil tree and the oil delivery pipeline 5, connect the suction pipe 3 and the casing valve 4 through the pipeline, install a one-way valve 7 in the suction pipe 3, and install a one-way valve in the one-way valve 7 Return spring 8, the fluid can only pass in the direction of the jet pump 2, and cannot pass in the opposite direction. When the oil well is pumped, the oil with a certain pressure and speed enters the jet pump 2, and a negative pressure is formed in the jet pump 2, the check valve 7 in the suction pipe 3 opens, and the natural gas in the casing 5 passes through the suction pipe 3 It is sucked into the jet pump 2, mixed with the oil in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com