Device for collecting oil well natural gas

A technology of collecting device and natural gas, which is applied in wellbore/well valve device, wellbore/well components, production fluid, etc., can solve the problems affecting well flushing operation and measuring dynamic liquid level, etc., to achieve simple construction and reduce environmental pollution. The effect of pollution and resource waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

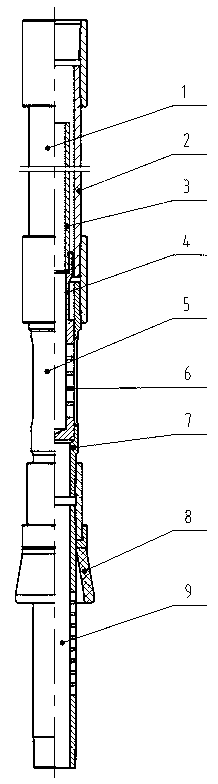

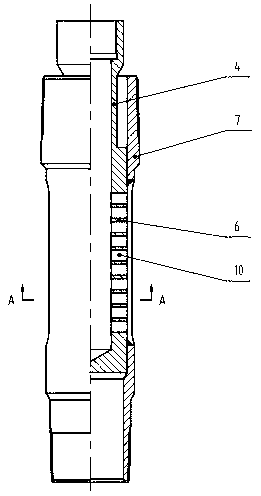

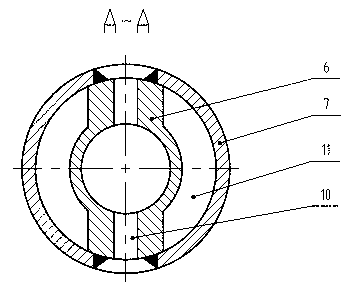

[0016] see figure 1 , is a structural diagram of an embodiment of the oil well natural gas collection device of the present invention, which is sequentially connected from bottom to top by a gas-liquid collector 9, a packer 8, an oil jacket communication valve 5 and a gas-liquid separator 1. The gas-liquid collector 9 is located at the bottom of the whole device to collect the oil and natural gas in the well fluid. The upper part of the gas-liquid collector 9 is equipped with a packer 8 to separate the oil casing annulus up and down. The upper part of the packer 8 Connect the oil jacket communication valve 5, and the oil collected by the gas-liquid collector 9 can enter the oil jacket annulus at the upper part of the packer 8 through the oil jacket communication valve 5 to form a dynamic liquid surface. The upper part of the oil jacket communication valve 5 is connected to the gas-liquid Separator 1, to separate the mixture of incoming natural gas and oil. The gas-liquid sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com