Cast-in-place belt net rack self-limiting sandwiched heat insulation plate for construction wall

A sandwich insulation board, insulation board technology, applied in the direction of insulation, construction, building components, etc., can solve the problems of increasing difficulty in construction, moving up and down the insulation board, inconvenient and fast fixing, etc., to improve service life, enhance strength and The effect of overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

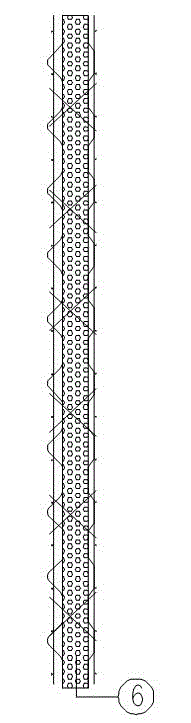

[0021] Attached below figure 1 , 2 , 3, 4, 5 describe the present invention in detail:

[0022] A kind of self-limiting sandwich insulation board with pouring grid frame for building wall, which includes insulation board (6), steel wire grid frame fixed to insulation board, and spacer for insulation board, and the steel wire grid frame fixed to insulation board includes the outer side The flat net 1, the inner flat net 2 of the insulation board, the outer flat net 1 of the insulation board, and the inner flat net 2 of the insulation board are connected and fixed by cross-connecting ribs 3;

[0023] The thermal insulation board limiter includes outer wave-shaped limit vertical ribs 4 and inner concave-convex limit vertical ribs 5 .

[0024] Horizontal ribs 7 are arranged between the outer flat net 1 of the insulation board and the inner flat net 2 of the insulation board to connect and fix them.

[0025] The crest position of the outer waveform limiting vertical ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com